Newsroom

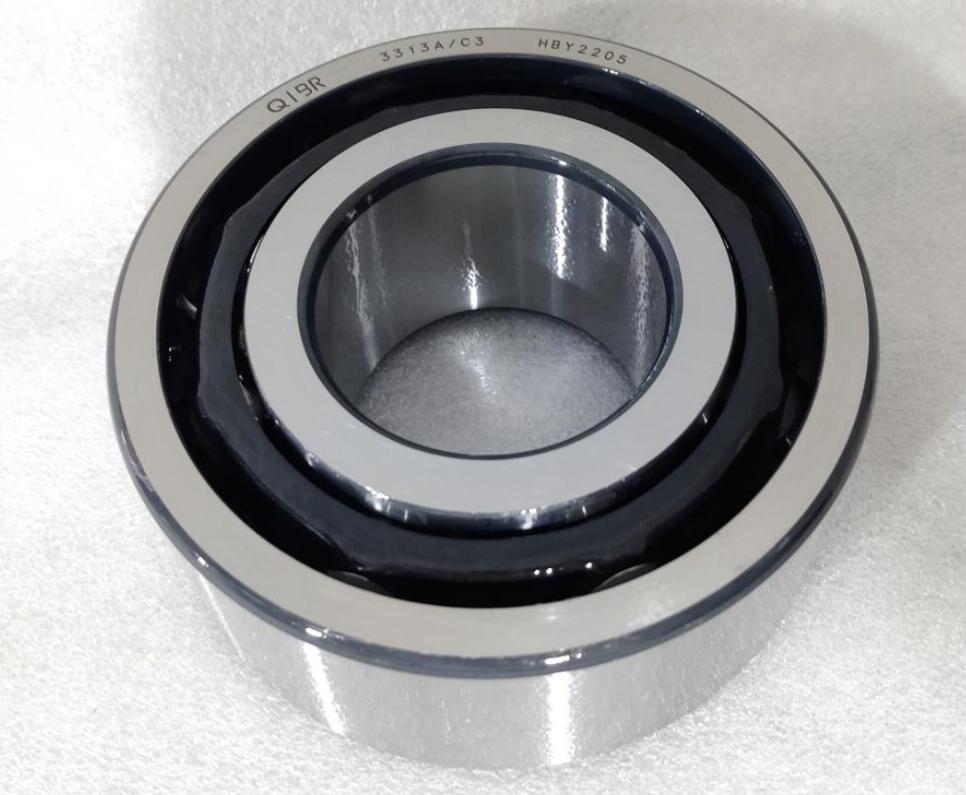

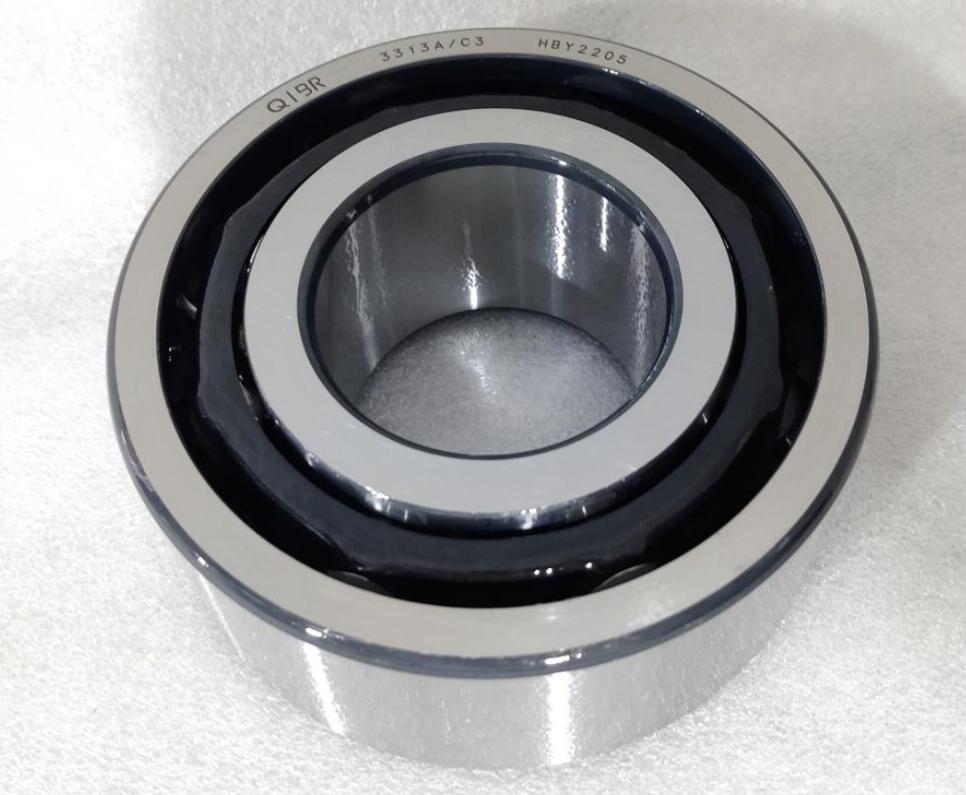

Double-Row Angular Contact Bearings for Automotive Air Conditioning Compressor Electromagnetic Clutches

2025-09-24  The double-row angular contact ball bearing used in the electromagnetic clutch of an automotive air conditioning compressor is a key precision component tailored to the special operating conditions of this core part. Its design features and performance advantages all center on the core requirements of "high load capacity, impact resistance, low friction, and long service life". A detailed breakdown is provided below:

The double-row angular contact ball bearing used in the electromagnetic clutch of an automotive air conditioning compressor is a key precision component tailored to the special operating conditions of this core part. Its design features and performance advantages all center on the core requirements of "high load capacity, impact resistance, low friction, and long service life". A detailed breakdown is provided below:

I. Core Structural and Performance Features

Double-row angular contact ball bearing (mostly of the 32 series such as 3203 and 3204) is designed with a special structure to adapt to the complex operating environment of electromagnetic clutches. Their main features are as follows:

1. Double-Row Rolling Elements + Symmetrical Contact Angle Design

Structural Characteristics:

The bearing contains two independent rows of steel ball rolling elements, and the outer ring (or inner ring) adopts a "symmetrical double raceway" structure. The contact angles of the two rows of steel balls (usually 15°, 25°, or 40°; 25° is commonly used in air conditioning compressor scenarios to balance axial and radial load-bearing capacity) are symmetrically distributed, together forming a "bidirectional load-bearing unit".

Function:

Unlike single-row angular contact bearings, which can only withstand axial loads in one direction, the double-row angular contact ball bearing can bear bidirectional axial loads and radial loads simultaneously. There is no need to match additional bearings, which simplifies the overall structure of the electromagnetic clutch.

2. Integrated Sealing/Dustproof Design

Structural Characteristics:

In response to the "high temperature, oil contamination, and dust" conditions of automotive air conditioning systems (the compressor is close to the engine and prone to contact with engine oil vapor and road dust), this type of bearing is mostly equipped with double-sided contact seals (2RS) or non-contact dust covers (2Z). It is pre-filled with long-life grease (usually polyurea-based grease resistant to high and low temperatures, suitable for a temperature range of -30℃ to 150℃).

Function:

- Prevent external oil contamination and dust from entering the bearing interior, avoiding wear on rolling elements and raceways;

- Prevent internal grease leakage, reduce maintenance needs, and ensure reliable lubrication of the bearing throughout its service life.

3. High-Rigidity Outer Ring and Compact Dimensions

Structural Characteristics: The outer ring is made of high-strength bearing steel processed by quenching and grinding, with a hardness of HRC 58-62, ensuring strong deformation resistance. Meanwhile, compared with the combination of two single-row bearings, the double-row design is more compact under the same radial dimensions, making it suitable for the "limited space" installation requirement of electromagnetic clutches.

Function:

- Withstand the instantaneous impact load when the compressor starts, preventing outer ring deformation;

- The compact dimensions reduce the overall volume of the electromagnetic clutch, improving the flexibility of engine compartment layout.

4. Low Friction Torque and High-Speed Adaptability

Performance Characteristics: By optimizing the precision of steel balls, the surface roughness of raceways (Ra ≤ 0.2μm), and adopting lightweight cages (e.g., nylon 66 cages), the friction torque of the bearing during operation is reduced. At the same time, the "force dispersion" of the double-row structure can increase the limiting speed of the bearing (usually up to 8,000-12,000 r/min, covering the conventional speed range of automotive air conditioning compressors: 1,500-8,000 r/min).

Function:

- Reduce the power loss of the electromagnetic clutch and lower engine fuel consumption;

- Prevent bearing failure due to frictional overheating at high speeds, improving reliability.

II. Core Advantages for Automotive Air Conditioning Electromagnetic Clutches

Compared with other types such as single-row angular contact bearings and deep groove ball bearings, double-row angular contact bearing excel in "operating condition adaptability" and "system reliability" in electromagnetic clutch scenarios.

First, in terms of bidirectional axial load capacity, the bearing can simultaneously bear the "electromagnetic coil engagement force" (axially inward) and the "compressor main shaft endplay reaction force" (axially outward) without the need for additional bearings—this simplifies the bearing layout of the electromagnetic clutch, reduces the number of components, and lowers both assembly complexity and failure rates.

Second, it offers excellent impact and vibration resistance: the double-row rolling elements can disperse instantaneous impact loads (such as torque impact during air conditioning start/stop), while the high-rigidity outer ring resists vibration transmission from the engine. This prevents "early spalling" of the bearing caused by impact, extending the service life of the electromagnetic clutch (with a conventional design life of ≥ 5,000 hours).

Third, it features maintenance-free operation and good environmental adaptability. Thanks to its sealed design and long-life grease, the bearing can operate stably in a temperature range of -30℃ to 150℃ and in environments with oil contamination and dust, without the need for intermediate grease replenishment. This makes it well-suited to the "harsh operating conditions" of automobiles, reducing after-sales maintenance costs and preventing air conditioning failure due to bearing damage.

Finally, it delivers high integration and low energy consumption. Its compact dimensions improve space utilization, while its low friction torque reduces power loss—compared with single-row bearings, friction torque can be reduced by 15%-20%. This complies with the automotive industry’s trends of "lightweight and low energy consumption" while ensuring the electromagnetic clutch’s response speed (with no delay in engagement or disengagement).