Newsroom

How Structure and Material of Bearing Cage Determine Functional Differences?

2025-11-05As the "framework" of bearings, the core function of bearing cage is to evenly separate rolling elements and prevent friction-induced jamming. Their structural design and material selection directly affect three critical performance indicators of bearings:

- Rotational speed

- Service life

- Applicable working conditions

Industry data highlights a critical point: approximately 35% of bearing failures stem from improper cage selection. Therefore, clarifying the functional differences between different bearing cage is essential for optimal bearing performance.

The structural design of bearing cage must balance three core factors: space occupation, rotational speed requirements, and assembly convenience. Currently, three mainstream structural types dominate the market, each tailored to specific scenarios:

I. Snap-type Cages: Ideal for Small-section Bearings

Fixing Method: Secured above rolling elements via elastic deformation of the snap feature.

Core Advantages:

- No need for additional assembly space.

- Guided by rolling elements at ambient temperature.

- Adaptive adjustment via raceway shoulder when temperature changes.

- Precise control of roundness and wall thickness reduces friction effectively.

Limitations:

- Only applicable to Type C and Type X bearings.

- Cannot meet the needs of ultra-small bearings with a cross-section below Class C.

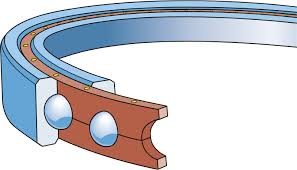

II. Circular Pocket-type Cages: Enhanced Load-bearing for Medium-speed Equipment

Design Feature: Adopts an integrated structure to accommodate more rolling elements.

Performance Boost: Load-bearing capacity increased by over 15% compared to traditional structures.

Key Specifications:

- Assembled via outer ring thermal expansion process.

- Compatible with Type A bearings.

- Supports processing with multiple materials (e.g., brass, nylon 66).

- Typical Applications: Motors, fans, and other medium-speed equipment.

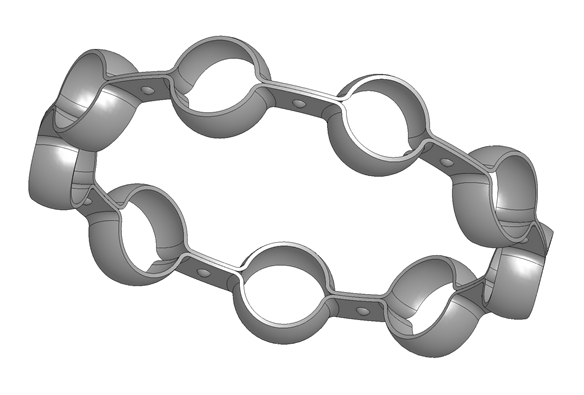

III. Two-piece Riveted Cages: Specialized for Ultra-high-speed Scenarios

Material Advantage: Machined phenolic laminate enables adaptation to high-speed environments.

Target Application: Equipment like centrifuges.

Limitations:

- Riveting process requires reserved space.

- Only suitable for bearings with a cross-section of Class D or above.

- Not ideal for small precision equipment.

Material properties directly determine three key characteristics of bearing cage: strength, temperature resistance, and friction performance. Below is a detailed comparison of three mainstream materials:

I. Steel Cages: Reliable for Medium-low Speed, Heavy-load Conditions

Main Types: Stamping steel cages and solid steel cages.

Key Properties:

- High strength and light weight.

- Maximum operating temperature: 300°C.

- Suitable Scenarios: Deep groove ball bearings and other heavy-load applications.

Drawbacks:

- Prone to rust, limiting use in humid environments.

- Maximum rotational speed approximately 30% lower than brass cages.

II. Brass Cages: Preferred for High-speed Equipment

Core Advantages:

- Low friction coefficient.

- High maximum rotational speed.

- Unaffected by lubricants like synthetic oils.

- Ideal Applications: Gearboxes, machine tool spindles, and other high-speed equipment.

Limitations:

- Cost over 40% higher than steel cages.

- Prone to failure in environments above 300°C or containing ammonia.

III. Nylon 66 Cages: Suitable for Precision, Low-load Scenarios

- Outstanding Features:

- Excellent self-lubricating properties.

- Strong anti-vibration capabilities.

- Operating temperature range: -40°C to 120°C.

- Typical Uses: Household appliances, precision instruments.

Shortcomings:

- Becomes brittle in a vacuum.

- Cannot withstand heavy loads, making it unsuitable for mining machinery.

Selection Guide: Matching Working Conditions is the Key

To select the right bearing cage, enterprises need to consider multiple factors and match them to specific working conditions. Below are targeted recommendations for common scenarios:

- For high-speed scenarios: Prioritize phenolic laminate riveted cages or nylon pocket-type cages. Both options can withstand high rotational speeds without experiencing performance degradation, ensuring stable operation even in fast-running equipment like centrifuges or high-speed motors.

- For high-temperature environments: Opt for stainless steel cages or brass cages. These materials maintain structural stability and functional integrity at elevated temperatures—brass cages, for example, can operate reliably up to 300°C, making them suitable for heat-intensive applications such as industrial ovens or high-temperature motors.

- For humid working conditions: Choose brass cages or nylon 66 cages. Avoid ordinary steel cages, as they are prone to rust when exposed to moisture. Brass and nylon 66 both offer good corrosion resistance, ensuring long-term performance in damp environments like water treatment equipment or outdoor machinery.

- For cost-sensitive equipment: Select stamping steel cages. They strike a balance between performance and affordability, meeting basic load and speed requirements while helping reduce overall equipment costs—ideal for mass-produced devices like household appliances or entry-level industrial machinery.