Newsroom

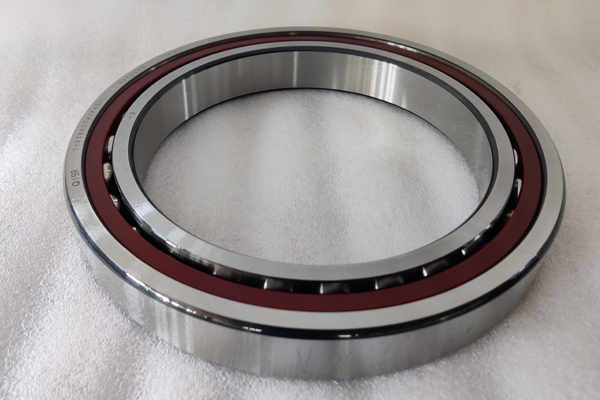

How to Determine Whether Angular Contact Ball Bearings Have Reached Wear Failure?

2025-10-17We use the following diagnostic technologies to determine whether angular contact ball bearings have reached wear failure.

I. Floating Oil Resistance Diagnosis

Technical Features:

This method evaluates the lubrication state by measuring the resistance of the oil film. The same evaluation standard can be used for different operating conditions. However, it is less effective for diagnosing abnormalities such as surface flaking, indentations, or cracks.

Application Field:

Suitable for installations where the rotating shaft is exposed.

2.Vibration Diagnosis

Technical Features:

Vibration analysis is a widely applied diagnostic technology. It allows online monitoring, provides quick results, and is supported by a mature theoretical foundation.

Application Field:

Highly suitable for fault detection in angular contact ball bearings used in rotating machinery.

3.Ferrography Diagnosis

Technical Features:

This method does not require disassembling the equipment. It offers low investment and significant effectiveness. It can detect early fatigue failures in oil-lubricated bearings and is useful for studying wear mechanisms.

Application Field:

Suitable for fault diagnosis in angular contact ball bearings lubricated with oil. However, it is more difficult to apply to bearings lubricated with grease.

4.Temperature Diagnosis

Technical Features:

A simple diagnostic method that performs well in identifying bearing overheating or burn damage.

Application Field:

Used for basic and simple condition monitoring of bearings in operating equipment.

5.Fiber-Optic Detection Diagnosis

Technical Features:

Fiber-optic angular displacement sensors offer high sensitivity. They can directly collect signals from the surface of oil-free bearings, improving frequency stability. This method can directly reflect the manufacturing quality, surface wear degree, load condition, lubrication state, and clearance of angular contact ball bearings.

Application Field:

Applicable to equipment where the sensor can be installed inside the bearing housing.

6. Acoustic Emission Diagnosis

Technical Features:

Fast and simple diagnostic method; can be used for online monitoring.

Application Field:

A relatively new technology that has been gradually applied to bearing condition monitoring but is still not widely used.

7.Maintenance and Handling Notes

During inspection, when manually handling oil-free bearings, clean off all sweat from your hands and apply high-quality mineral oil before touching the bearing. Extra care should be taken during the rainy season and summer to prevent rust.

Under certain special operating conditions, angular contact ball bearings may achieve longer service life than conventional theoretical calculations suggest — particularly under light loads. These favorable conditions occur when the rolling surfaces (raceways and rolling elements) are effectively separated by a stable lubricating film and protected from contaminants that could cause surface damage.

In fact, under ideal conditions, a so-called “permanent bearing life” is theoretically possible.