Newsroom

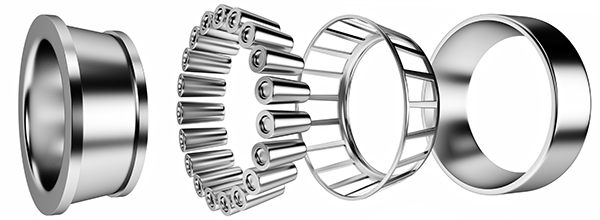

How to disassemble bearings?

2018-12-25Importance of bearing disassembly

Ensure equipment maintenance and replacement and prolong the service life of equipment.

Correct disassembly avoids damage to bearings and other parts.

I. Safety first is the key

Dangers are prone to occur during operation, such as metal fragments flying due to bearing breakage.

It is strongly recommended to add a protective blanket to ensure operation safety.

II. Classification of bearing disassembly

For clearance fit bearings, those without deformation or corrosion can be directly removed.

Interference fit bearings are the core problem, which can be divided into inner ring interference and outer ring interference.

III. Disassembly methods for inner ring interference and outer ring clearance fit

Cylindrical shaft

- For small-sized bearings, use a puller, which can be divided into threaded and hydraulic types.

- For special designs, two-piece splints or quick-disassembly hydraulic devices can be used.

- For large-sized bearings, special tooling needs to be designed. The inner ring can be expanded by pressurizing through oil holes.

- For oversized bearings, use the heating disassembly method. Prepare tools to heat the inner ring with a coil to make it expand.

Conical shaft

Disassemble by heating the large end face of the inner ring. When used in pairs, removing one can expose the other.

For large-sized conical shafts, use the disassembly oil hole and disassemble by applying pressure in sequence.

Do not completely remove the clamping nut before disassembly to prevent the bearing from falling.

IV. Disassembly methods for different types of bearings

Bearings installed on cylindrical shaft diameters

- For cold disassembly, punches or mechanical pullers can be used. For small bearings, the heating method can also be used.

- For hot disassembly, there are heating rings and adjustable induction heaters.

Bearings installed on conical shaft diameters

For small bearings, use mechanical or hydraulic-assisted pullers. For large ones, use the oil injection method.

Bearings installed on adapter sleeves

- For small bearings, small steel blocks or special sleeves can be struck, or hydraulic nuts can also be used.

- For adapter sleeves with oil holes and oil grooves, the oil injection method can be used.

Bearings installed on withdrawal sleeves

For small and medium-sized ones, use tools such as lock nuts. For medium and large-sized ones, use hydraulic nuts.

V. Common disassembly methods and precautions

Percussion method

Apply the percussion force to the inner ring. Pay attention to the position of the cushion block and the force application point.

Pulling method

The puller hooks the inner ring. Pay attention to aligning the screw rod with the center hole and preventing the puller from slipping off.

Pushing method

The press applies pressure smoothly and reliably. The force application point is at the center of the shaft.

Hot disassembly method

Heat to about 100°C and pour in engine oil. Pay attention to installing the puller in advance and wrapping the shaft.

VI. Other methods for disassembling equipment bearings

The percussion method should be gradual to avoid damaging the shaft or bearing by heavy percussion.

- For the pulling method, use a special hydraulic puller. For small ones, a mechanical puller can be used.

- For the hot disassembly method, pay attention to the position of the pull claw, the wire is not skewed, prevent the pull claw from slipping off, and heating matters.

By following these steps, you can effectively find and use interchangeable bearings for your applications. If you have a specific bearing in mind that you need to interchange, let me know, and I can help further!