Newsroom

How to install full-complement needle roller bearings?

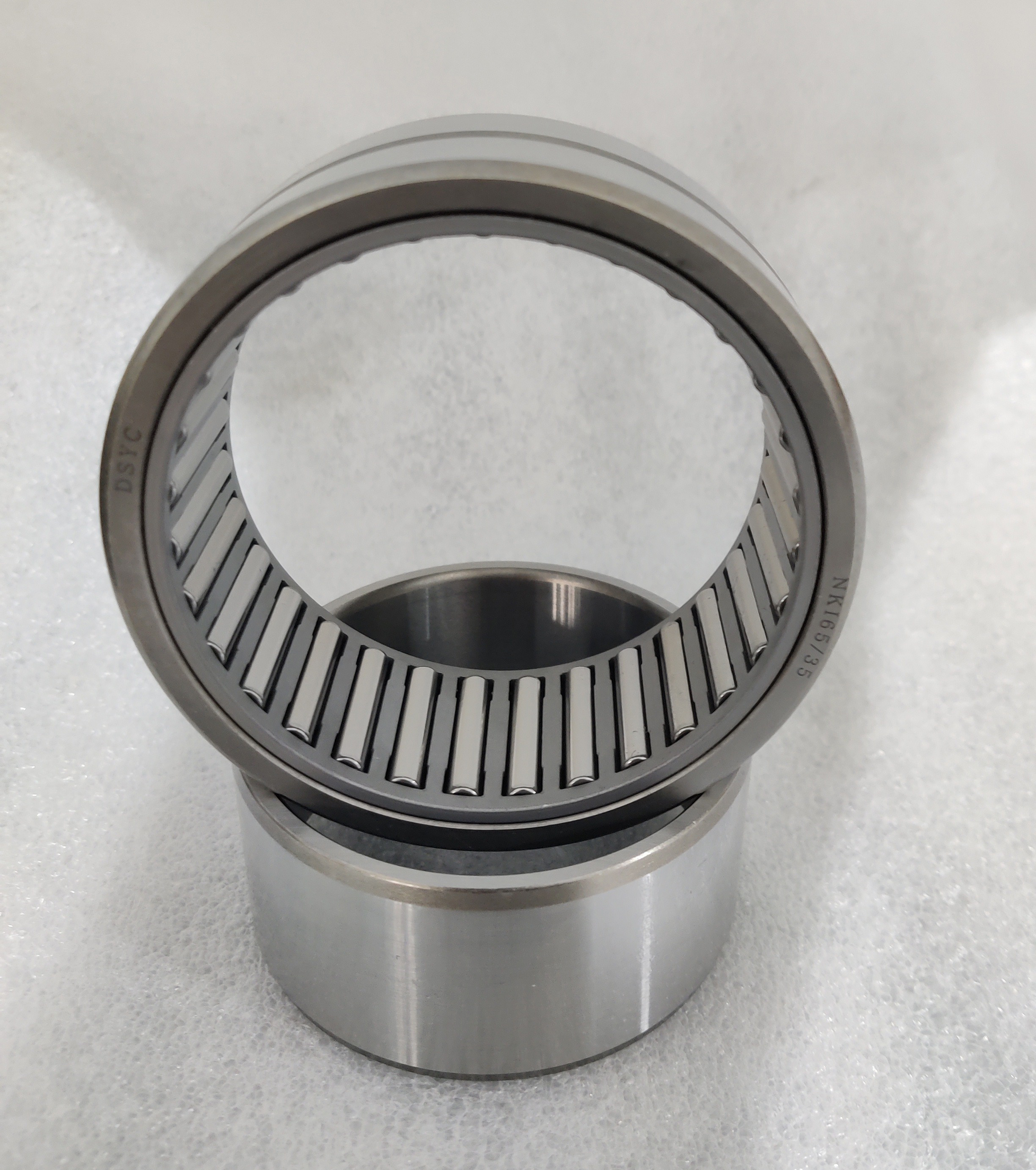

2025-08-08Full-complement needle roller bearings are a variant of standard needle roller bearings. They differ by eliminating the cage, allowing the bearing to be fully filled with rollers between the inner and outer rings. As there is no cage to retain the rollers, careful handling during installation is essential to ensure the rollers remain in place and properly aligned.

1.Preparation Before Installation Needle Roller Bearings

- Check Fit Dimensions: Ensure the shaft and housing bore meet the bearing’s fit tolerance.

- Lubrication: Apply a thin layer of grease to the inner surface of the bearing’s outer ring to hold the rollers in place.

- Prepare Auxiliary Tools: Use an auxiliary sleeve or roller to assist with installation. The outer diameter should be 0.1–0.3 mm smaller than the shaft diameter.

2.Installation with Inner and Outer Ring

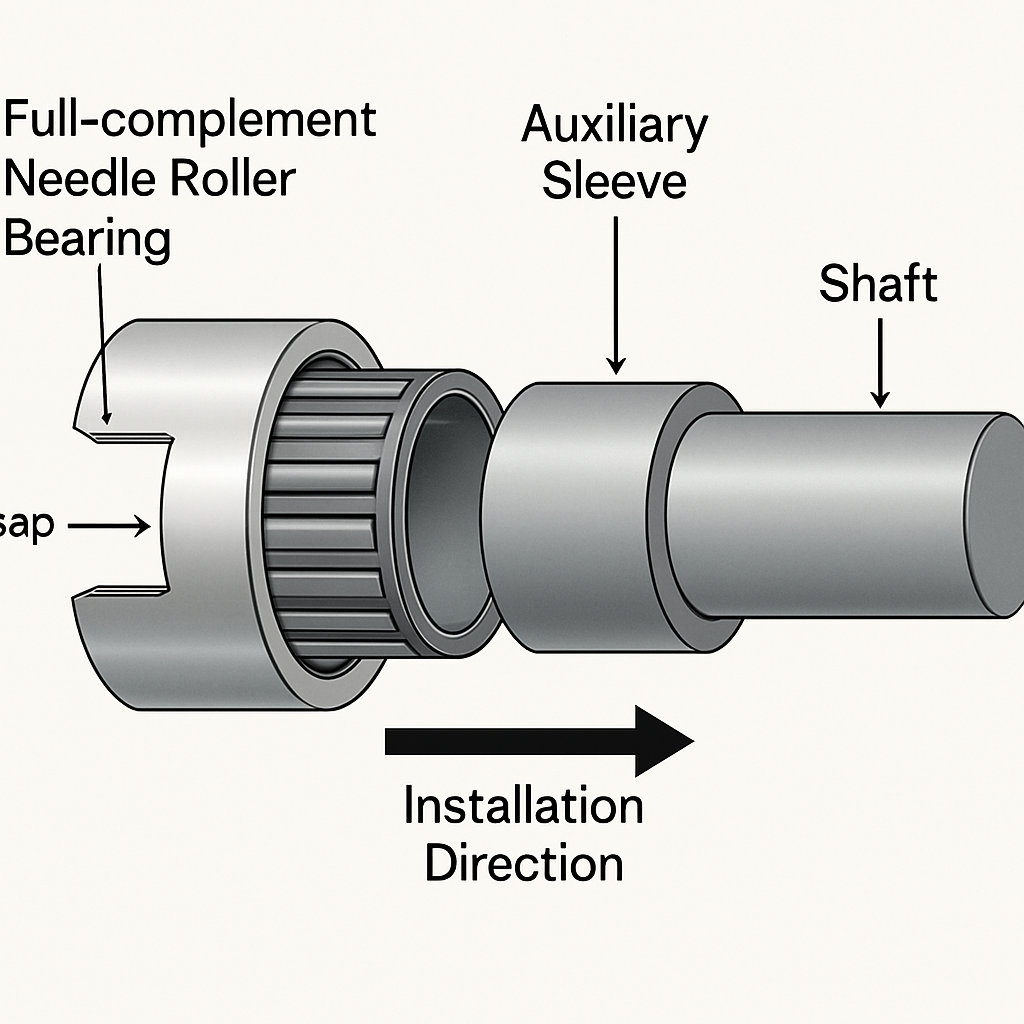

- Method 1: Using an Auxiliary Sleeve to Guide Rollers into Position

I. Apply grease to the inner surface of the outer ring.

II. Insert the rollers one by one along the raceway (leave a 0.5 mm gap when placing the last roller).

III. Insert the auxiliary sleeve (used in place of the shaft or inner ring) into the outer ring, forming a continuous guide path.

IV. Align the sleeve with the shaft end face (or inner ring) and press the bearing inward slowly using a press or soft-faced hammer.

V. As the bearing moves inward, the shaft will push out the auxiliary sleeve, completing the installation.

- Method 2: Insert Sleeve First, Then Install Rollers

I. Lightly oil the outer surface of the auxiliary sleeve.

II. Insert the sleeve into the outer ring to form an annular space.

III. Place the rollers into the annular gap one by one (leaving 0.5 mm gap for the last roller).

IV. Insert the shaft to push out the auxiliary sleeve, completing the process.

3. Installation for Needle Roller Bearings Without Inner or Outer Rings

Without Inner Ring:

- Apply grease to the shaft surface.

- Attach rollers one by one directly onto the shaft.

- Leave a 0.5 mm gap before placing the final roller.

- Press the outer ring or mating component into place.

Without Inner Ring:

- Apply grease to the housing bore.

- Place rollers directly into the bore one by one.

- Leave a 0.5 mm gap at the end.

- Insert the inner component (e.g., shaft) to complete installation.

4. Important Notes

- Do not forcibly insert the last roller, as it may cause the bearing to jam.

- Do not omit a roller, as this may lead to excessive clearance, causing roller skewing or breakage during operation.

- For drawn cup needle roller bearings, use a press for installation instead of a hammer to avoid localized deformation of the thin-walled outer ring.

For more information, feel free to contact QIBR