Newsroom

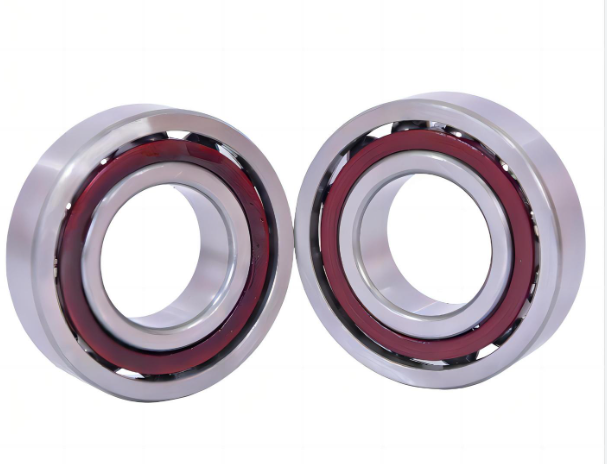

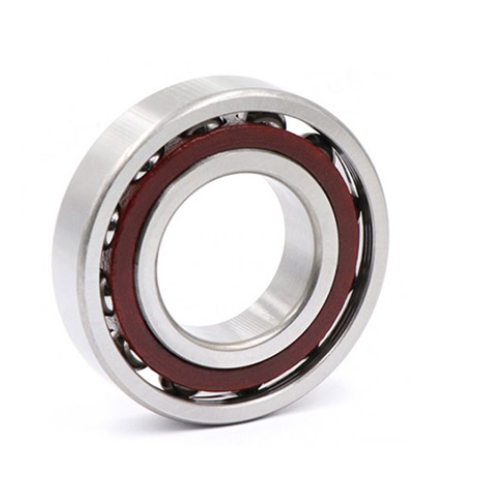

How to Prevent Failure of Miniature Angular Contact Bearings?

2025-05-09To effectively prevent the failure of miniature angular contact bearings, the following measures can be taken:

1.Select bearings suitable for the application

When choosing miniature angular contact bearings, it's important to consider operating conditions such as speed, load, ambient temperature, and humidity. Selecting bearings appropriate for the application can enhance their service life and reliability.

2.Control lubrication

Proper lubrication is essential to reduce friction and wear. Choose the right lubricant and control its quantity and viscosity to avoid insufficient or excessive lubrication.

3.Prevent contamination

Miniature angular contact bearings are highly susceptible to contamination from fine particles and foreign matter, which can increase friction and wear. Measures should be taken to prevent contaminants from entering the bearing environment, such as using sealed bearings or filters.

4.Proper installation and removal

Use the correct tools and techniques when installing and removing miniature angular contact bearings to avoid damaging them. Follow the manufacturer’s recommendations for installation and adjustment to ensure proper operation.

5.Regular maintenance and inspection

Periodic maintenance and inspection—including checking the lubrication condition, cleaning or replacing lubricants, and inspecting for damage or wear—can help identify and resolve issues early, preventing bearing failure.

6.Choose high-quality bearings

Using high-quality miniature angular contact bearings ensures better material quality and manufacturing precision, reducing the risk of failure.

7.Consider the operating environment

The service life of miniature angular contact bearings can be affected by their environment. High temperature, humidity, or corrosive conditions can shorten bearing life. Take appropriate measures such as enhancing cooling, moisture protection, and corrosion resistance based on the working environment.

8.Design the bearing housing properly

An improperly designed bearing housing can lead to uneven load distribution, local overload, or unbalanced forces, which may cause bearing failure. The housing design should take into account the characteristics and requirements of miniature angular contact bearings to ensure stable support and balanced loading.

9.Replace bearings periodically

Miniature angular contact bearings have a finite service life and should be replaced when due. Develop a replacement schedule based on the actual usage and the manufacturer's recommendations to prevent unexpected failure.

Preventing failure of miniature angular contact bearings requires a comprehensive approach that includes proper selection, maintenance, and management. Additionally, attention should be paid to the operating environment and working conditions to ensure optimal performance.

For more information, feel free to contact QIBR