Newsroom

How to use slewing bearings?

2022-06-24How to use slewing bearings?

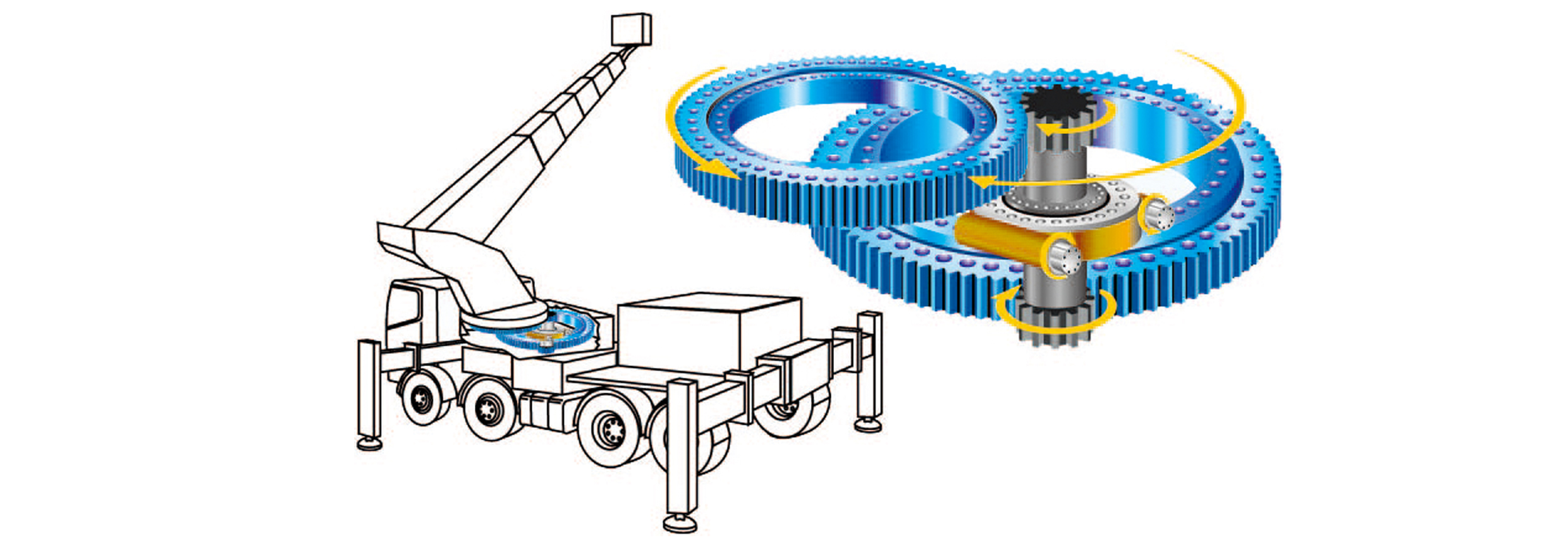

Slewing bearings are indispensable key components in modern machinery, widely used in equipment requiring rotational movement and load-bearing capacity. They are typically installed at the end of each shaft in the equipment, ensuring smooth rotational motion. Whether in large cranes, heavy grapples, forklift attachments, or other devices needing rotational capability, slewing bearings play a crucial role.

Classification and Function of Slewing Bearings

Slewing bearings are primarily categorized into three types: internal gear, external gear, and gearless. Internal gear slewing bearings have the gear portion inside the bearing, a design often used in equipment requiring compact installation space. External gear slewing bearings, in contrast, have the gear portion on the outside of the bearing, suitable for external installation and maintenance. Gearless slewing bearings lack a gear portion and rely on other methods for rotational movement, typically used in specialized applications or equipment with specific gear drive requirements.

The core function of slewing bearings is to bear various forces exerted on rotating equipment, including axial force, radial force, and tilting moment. Axial force refers to the force acting along the axis of the bearing, while radial force is perpendicular to the axis. The tilting moment is the torque resulting from uneven distribution of external loads, causing the bearing to tilt. Slewing bearings, through their unique design and structure, effectively distribute and bear these forces, ensuring the smooth operation of equipment.

Application Areas of Slewing Bearings

In practical applications, slewing bearings are widely used in various equipment requiring rotational movement and load-bearing capabilities. For instance, in large cranes, slewing bearings are typically installed at the base of the rotating platform, bearing the weight of the entire upper structure of the crane and allowing for 360-degree rotational operations. In heavy grapples, slewing bearings support the rotational movement of the grapple, enabling it to flexibly grab and place heavy objects.

Additionally, slewing bearings are extensively applied in construction equipment, transportation equipment, and wind power generation equipment. In construction equipment, such as tower cranes and excavators, slewing bearings are crucial components that determine the stability and operational precision of the equipment. In transportation equipment, such as large trucks and wheel loaders, slewing bearings ensure the smooth rotation of the wheels and the stable operation of the equipment. In wind power generation equipment, slewing bearings support the rotation of wind turbine blades, enabling them to efficiently capture wind energy and convert it into electricity.

Design and Selection of Slewing Bearings

The design and selection of slewing bearings are key to ensuring optimal performance in specific applications. During the design process, factors such as bearing capacity, rotational speed, working environment, and specific equipment requirements need to be considered. For high-load applications, slewing bearings with strong load-bearing capacity should be selected, while for high-speed rotational applications, bearings capable of withstanding high-speed operations are necessary. Additionally, factors such as temperature, humidity, and possible corrosive substances in the working environment must also be considered during design and selection.

In practical applications, the installation and maintenance of slewing bearings are also crucial. Proper installation ensures the normal operation of the bearings, while regular maintenance can extend their service life. Typically, during installation, it is essential to align the bearing's center with the rotation center of the equipment to avoid excessive wear due to misalignment. Additionally, regularly checking the bearing's lubrication, and timely adding or replacing lubricant, can effectively reduce friction and wear, prolonging the bearing's lifespan.

Future Development Trends

With technological advancements and the ever-changing industrial demands, slewing bearings are continuously evolving and innovating. In the future, slewing bearings will move towards becoming more lightweight, precise, and reliable. The application of new materials and processes will further enhance the bearing's load-bearing capacity and durability. Meanwhile, with the development of automation and intelligent technologies, slewing bearings will gradually integrate into intelligent monitoring and control systems, enabling real-time monitoring of bearing conditions and fault prediction.

In summary, slewing bearings, as a crucial rotating structural component, have already played an irreplaceable role in various industries and fields. Through continuous technological innovation and optimized design, slewing bearings will continue to play an important role in future machinery, providing strong support for the stable operation of various equipment.