Newsroom

In which fields are 6000z bearings applied?

2024-09-26As an indispensable key component in mechanical equipment, bearings play an important role in various industrial fields. As a common deep groove ball bearing, 6000z bearings are widely used in many fields due to their unique performance and characteristics.

Structure and characteristics of 6000z bearings

6000z bearings are a kind of deep groove ball bearings, which are composed of inner rings, outer rings, steel balls and cages. Its main characteristics include:

Simple structure: The structure of deep groove ball bearings is relatively simple and easy to install and disassemble.

Moderate load-carrying capacity: It can bear a certain radial and axial load.

Good high-speed performance: Suitable for high-speed rotation occasions.

Low friction coefficient: Reduce energy loss and improve the efficiency of equipment.

Good sealing performance: 6000z bearings are equipped with metal dust covers (Z indicates a single-sided metal dust cover), which can effectively prevent dust and impurities from entering the bearing interior and protect the normal operation of the bearing.

The specific applications of 6000z bearings are in the following fields:

Household appliances

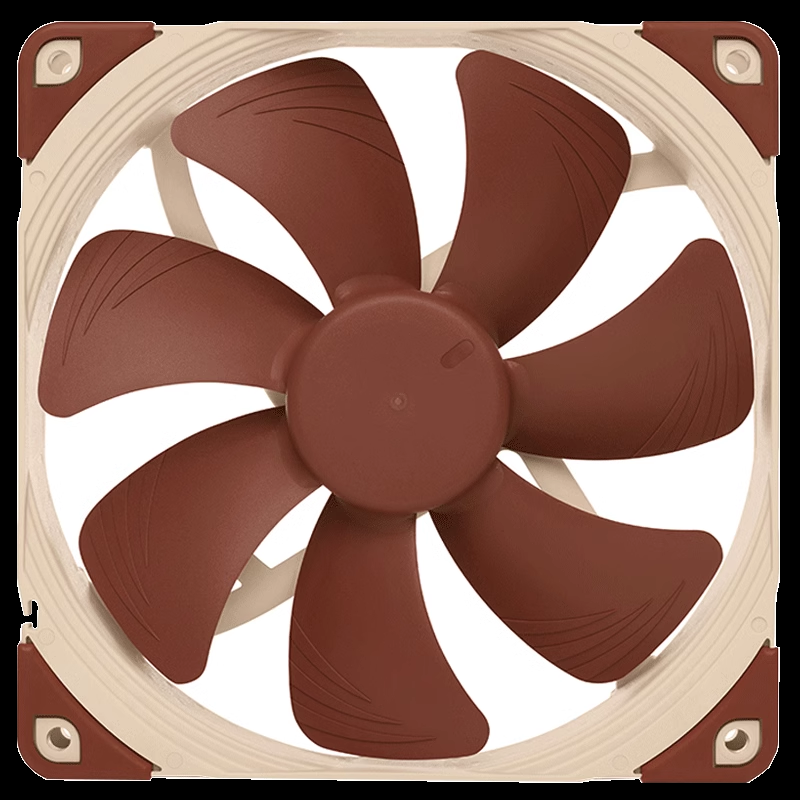

In household appliances such as washing machines, electric fans, and air conditioners, 6000z bearings are widely used in components such as motors and fans. Its high-speed performance and low-noise characteristics can provide stable operation and a good user experience for household appliances.

For example, the motor of a washing machine usually needs to use bearings to support the rotation of the rotor. The load-carrying capacity and stability of 6000z bearings can meet the needs of washing machines in different working states.

Power tools

In power tools such as electric drills, angle grinders, and electric saws, 6000z bearings are often used in motors and transmission components. Power tools need to bear large impact loads and high-speed rotations during operation. The impact resistance and high-speed performance of 6000z bearings can ensure the reliability and service life of power tools.

For example, 6000z bearings are usually installed on the motor shaft of an electric drill to ensure high-speed rotation and stable output of the motor.

Office equipment

In office equipment such as printers, copiers, and scanners, 6000z bearings are used in components such as motors and transmission gears. Office equipment requires low noise, high precision and high reliability. The characteristics of 6000z bearings can meet these requirements.

For example, 6000z bearings are usually used on the ink cartridge drive shaft of printers to ensure the accurate movement of ink cartridges and printing quality.

Medical devices

In medical devices such as blood glucose meters, blood pressure monitors, infusion pumps and other equipment, 6000z bearings also have certain applications. These devices have high requirements for precision and reliability. The low friction coefficient and high-speed performance of 6000z bearings can provide stable operation and accurate measurement results for medical devices.

For example, 6000z bearings may be used in the motor and transmission components of blood glucose meters to ensure the accuracy and reliability of the equipment.

Industrial machinery

In various industrial machinery such as machine tools, fans, pumps and other equipment, 6000z bearings are also widely used. Industrial machinery usually needs to bear large loads and high-speed rotations. The load-carrying capacity and high-speed performance of 6000z bearings can meet these requirements.

For example, 6000z bearings may be used on the main shaft and feed shaft of machine tools to ensure the machining precision and efficiency of machine tools.

Before installing 6000z bearings, carefully check the appearance of the bearings to ensure that there are no defects such as damage, cracks, and rust. At the same time, check whether the size of the bearing meets the requirements to ensure the fitting accuracy with the installation part. Regularly check the operating status of the bearing. If any abnormality is found, it should be dealt with in time to avoid affecting the normal operation of the bearing.

For more information, feel free to contact QIBR