Newsroom

Is the surface roughness of the slewing bearing as small as possible? How to choose?

Is the surface roughness of the slewing bearing as small as possible? Surface roughness refers to the unevenness of the small spacing and tiny peaks and valleys on the machined surface. The roughness of the bearing surface may affect the wear resistance, stability, fatigue strength, stability and other properties of the bearing. Generally speaking, the smaller the roughness of the bearing surface, the better, but it still needs to be determined according to the equipment use requirements and process accuracy.

I.The surface roughness of the slewing bearing is not as small as possible

Is the surface roughness of the slewing bearing as small as possible? It can be analyzed from the following aspects:

1. Physical properties of materials

The surface roughness of the bearing is often represented by Ra. Generally speaking, from the working principle, we hope that the surface roughness of the slewing bearing is as small as possible. Generally, the higher the tolerance accuracy level of the bearing, the better the surface quality and the finer the workmanship. However, two too smooth surfaces are prone to bonding when in contact under pressure (exchange between the same or similar materials, which is similar to the "dyeing phenomenon" in our lives, but here it belongs to the exchange of metal substances), while too rough surfaces are prone to peeling off under force (which is what we often call wear).

2. Processing cost

Theoretically, the smaller the value of the surface roughness of the slewing bearing, the better. The smaller the roughness, the smoother the surface and the more beautiful the appearance. However, the degree of roughness is determined by the processing technology and other factors, such as friction and cutting between the tool and the bearing surface, and high-frequency vibration in the process processing.

However, the smaller the surface roughness, the higher the processing cost. Whether the cost of using the parts matches the consumption speed and the profit of the equipment production output value. These are all things that need to be considered. Some spare parts do not require high surface roughness of the bearing. Excessive pursuit of surface roughness will affect the economy of processing.

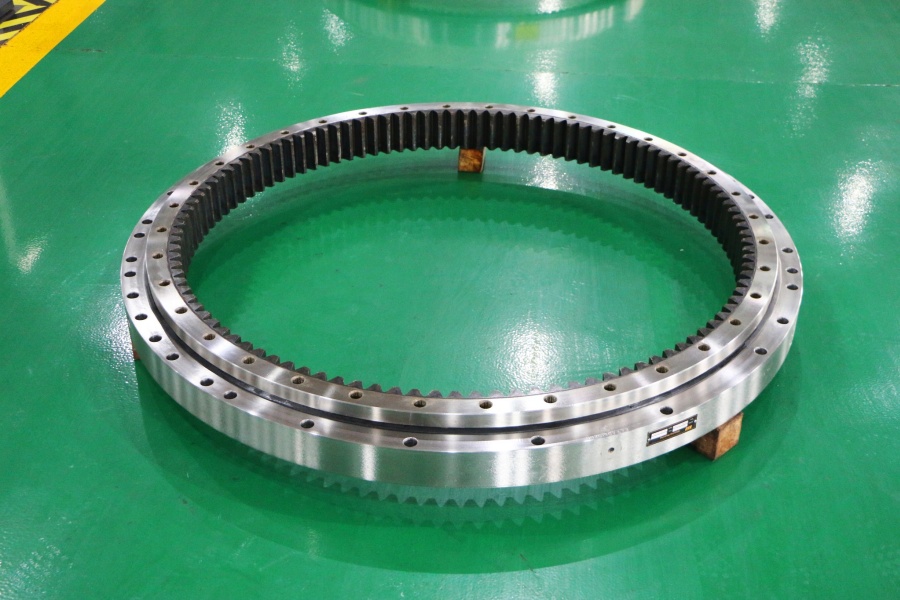

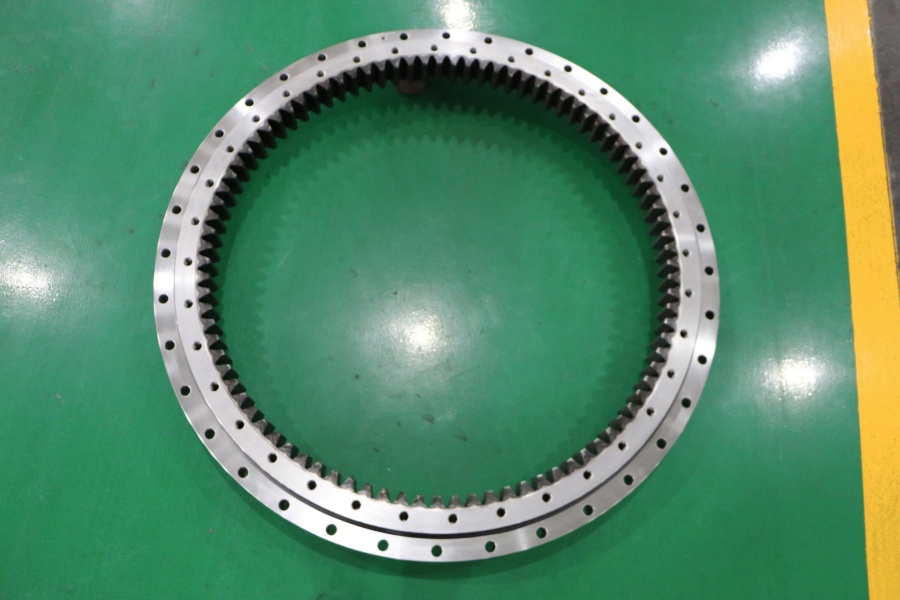

Three-row roller internal gear structure model

II. Principles for selecting the surface roughness of the slewing bearing

1. Economic perspective: From an economic perspective, on the basis of meeting the performance requirements of the slewing bearing, the lower the accuracy, the better. This can reduce production costs.

2. Function of use:

(1) The roughness value of the working surface is smaller than that of the non-working surface.

(2) The roughness value of the friction surface is smaller than that of the non-friction surface.

(3) The roughness value of the clearance fit is smaller than that of the interference fit.

(4) The roughness of the mating surface should be equivalent to its dimensional accuracy requirements. The smaller the size, the smaller the roughness value.

(5) The roughness value of the surface subjected to periodic loads and the inner fillet and groove where stress concentration may occur should be smaller.