Newsroom

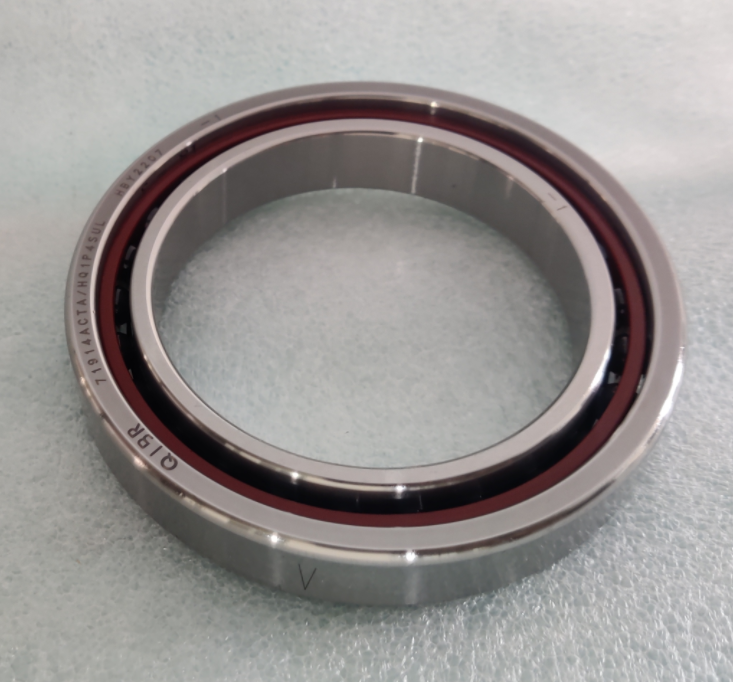

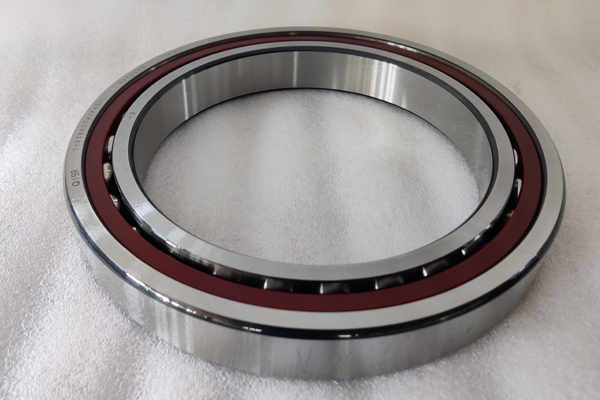

Key Points for Visual Inspection of Precision Angular Contact Ball Bearings?

2025-06-27When conducting a visual inspection of precision angular contact ball bearing, attention should be paid to the following aspects:

1.Crack Inspection:

Check for any of the following types of cracks on precision angular contact ball bearing components:

- Raw material cracks

- Forging cracks

- Heat treatment cracks

- Grinding cracks

Risk:

These cracks act as stress concentration points during precision angular contact ball bearing operation, leading to rapid crack propagation and bearing fracture. This severely impacts precision angular contact ball bearing life and operational safety.

Control Measures:

For critical applications, QIBR performs 100% magnetic particle or radiographic inspection on precision angular contact ball bearing components to ensure they are free from cracks.

2.Mechanical Damage Inspection:

Look for surface damages such as:

- Scuff marks

- Scratches

- Indentations

- Impact marks

Impact:

Such damages can cause improper installation, misalignment, and stress concentration, leading to reduced rotation accuracy and service life.

3.Surface Corrosion and Defects:

- Rust

- Scale (Black Oxide Layer)

- Pitting

Risk:

Scale and pitting can trap moisture and contaminants, making the precision angular contact ball bearing prone to rust. Rust can result in poor installation, early wear, and fatigue failure. Severely rusted bearings should be rejected.

4.Material Defects:

- Laps

- Folds

Risk:

These areas have poor bonding with the base metal and are often accompanied by decarburization or low-carbon zones. They are prone to flaking, indentation, and wear, severely affecting precision angular contact ball bearing accuracy and lifespan.

5.Cage Quality Inspection:

Key points to check:

- Riveting quality: Check for misalignment, skewed rivets, looseness, material deficiency, or double-layer defects (“double eye-lid” effect).

- Welding quality: Ensure correct welding position and appropriate weld size. Check for weak welds or excessive welding that may cause rolling elements to jam.

- Forming quality of the cage: Inspect crimping, edge finishing, seam closing, and notch quality.

- Rolling element retention: Rolling elements must not fall out and should rotate freely.

Impact:

Poor cage quality may lead to noise, reduced rotational accuracy, or, in severe cases, cage breakage causing machine failure or accidents.

6.Marking Quality:

- Markings must be clear and legible.

- Blurred or damaged markings will classify the bearing as defective.

- Serious marking defects may lead to outright rejection.

7.Assembly Surface Inspection:

No visible burns or tempering marks are allowed on the assembly surfaces.

Impact:

Burns or tempering marks affect surface hardness and bearing performance.

8.Assembly Surface Inspection:

If any of the above defects are found during inspection, the precision angular contact ball bearing must be rejected.

For more information, feel free to contact QIBR