Newsroom

Needle Roller Bearing: Empowering the Automotive Industry, Bearing "Great Power" with "Compact Size"

2025-10-22  Amid the wave of the automotive industry's transformation towards new energy and intelligence, needle roller bearing, with their unique advantages, have become core components ensuring the efficient operation of vehicles. This article analyzes their key applications and development trends in the automotive industry starting from their core characteristics.

Amid the wave of the automotive industry's transformation towards new energy and intelligence, needle roller bearing, with their unique advantages, have become core components ensuring the efficient operation of vehicles. This article analyzes their key applications and development trends in the automotive industry starting from their core characteristics.

I. Core Advantages of Needle Roller Bearings

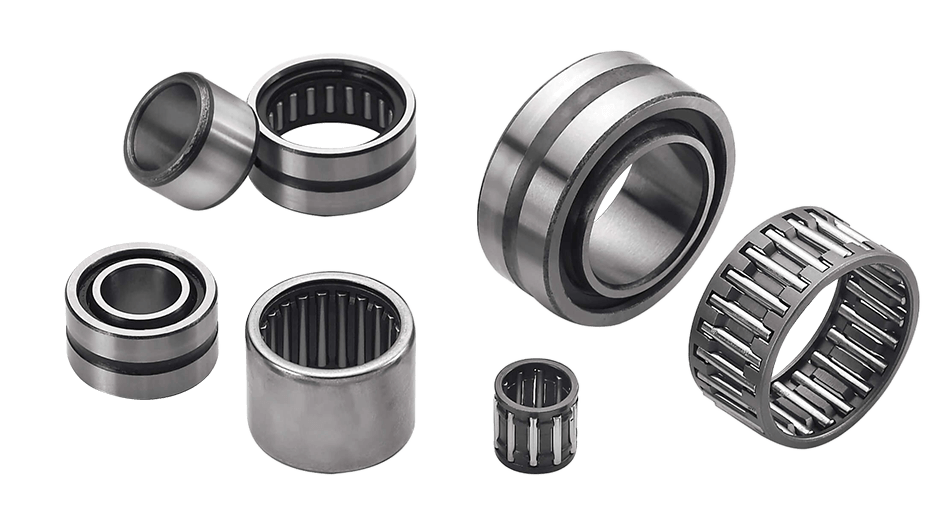

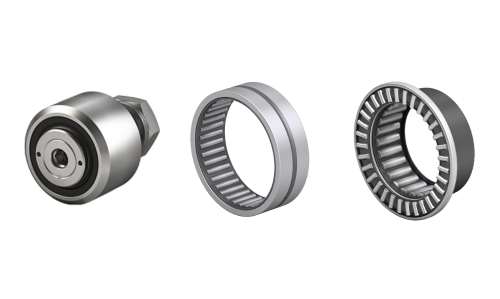

- High Load-Bearing Capacity + Compact Structure: The rolling elements are slender steel needles with a diameter ≤ 5mm, forming line contact with the inner and outer rings. Under the same space, their radial load-bearing capacity is 2-8 times higher than that of ball bearings, making them perfectly suitable for space-constrained and heavy-load scenarios in automobiles such as gearboxes and engines.

- Low Friction + Low Noise: The steel needles undergo precision grinding and are matched with dedicated cages, resulting in a friction coefficient as low as 0.001-0.002. This can reduce power loss and adapt to the high-speed operating conditions of engines (6,000-8,000 rpm) and new energy vehicle motors (over 20,000 rpm).

- Rich Variety + Strong Adaptability: They include drawn cup needle roller bearing (lightweight and low-cost), solid needle roller bearing (high strength and precision), and needle roller thrust bearing (bearing radial + axial loads), etc., to meet the needs of multiple automotive systems.

II. Core Applications in the Automotive Industry

(I) Gearboxes: Ensuring Smooth Gear Shifting

- Shift Fork Shafts: Planar needle roller bearing disperses the impact during gear shifting and reduce resistance. For example, the INA bearings used in the Volkswagen MQ200 gearbox reduce gear-shifting resistance by 15%-20% and extend the service life by 3 times.

- Planetary Gears: Solid needle roller bearings or needle roller thrust bearings ensure stable rotation. The bearings developed by NSK for the Toyota Aisin 6AT can bear an axial load of 1,500N and reduce friction loss by 20%.

- Domestic Breakthrough: QIBR Bearing supplies bearings for the BYD gearbox, with a fatigue life of over 8,000 hours.

(II) Engines/Motors: Improving Power Efficiency

- Internal Combustion Engines (ICE) for Fuel Vehicles: Needle roller bearing is used in piston pins, converting sliding friction into rolling friction, which increases mechanical efficiency by 3%-5%. Luoyang LYC Bearings, which supplies bearings for Changan Blue Core engines, improves fuel economy by 2%-3%.

- New Energy Vehicle Motors: The high-speed bearings developed by QIBR use silicon nitride ceramic needles, adapting to motors with a speed of 20,000 rpm and reducing energy loss by 10%-12%.

- Differentials: INA bearings, after carburizing and quenching, can bear a torque of 3,000N·m and are used in BMW X5 and Mercedes-Benz GLE.

(III) Auxiliary Systems: Optimizing Driving Experience

- Air Conditioning Compressors: Needle roller bearing from QIBR Bearing reduce energy consumption by 8%-12%.

- Steering Systems: INA engineering plastic bearings are maintenance-free at -40℃ to 120℃, installed in Audi A6L and Volkswagen Magotan to improve steering accuracy.

- Clutches: Schaeffler planar bearings reduce pedal force by 20%-30% and have a service life of over 150,000 kilometers, used in Volkswagen Golf.

III. Innovative Upgrades Adapting to Automotive Trends

- Material Innovation: Application of silicon nitride ceramics and graphene coatings. The graphene bearings from China enable maintenance-free wheel ends of heavy-duty trucks for 500,000 kilometers.

- Process Upgrades: Ultra-precision CNC grinding (roughness Ra 0.02μm) and automated production lines. The production line of QIBR has a pass rate of 99.9%, and its market share of new energy vehicle bearings reached 14.3% in 2024.

- Intelligent Integration: Schaeffler's intelligent bearings integrate sensors to monitor status in real time, with a fault prediction accuracy of 98%, installed in Porsche Taycan and Audi e-tron.