Newsroom

QIBR Joint Bearings Fit Selection Guide

2025-11-07Precision Fit, Smooth Motion, Reliable Performance

In construction machinery, aerospace systems, and automated equipment, joint bearings play a crucial role in enabling precise motion and carrying multi-directional loads.

Their performance depends not only on material and structure — but also on fit tolerance between the shaft and housing.

Even a minor mismatch in fit can turn smooth operation into frequent jamming or premature wear.

That’s why at QIBR, we emphasize:

Correct fit selection is the first step toward bearing reliability.

1.Different Conditions Require Different Fits – Precision Matching Is the Key

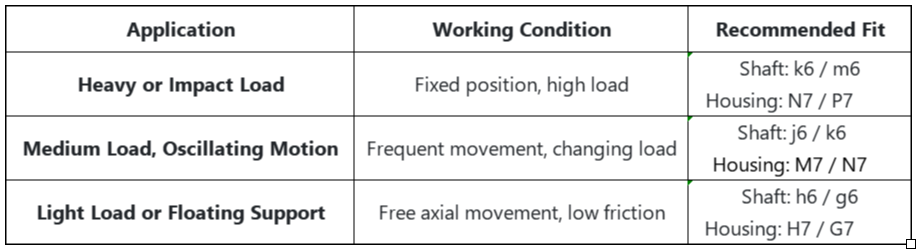

The appropriate bearing fit varies greatly depending on load type, support mode, and motion pattern.

Based on years of experience and industry standards, QIBR recommends the following fit guidelines:

QIBR Tip:

Use a slight interference fit on the fixed side to prevent fretting wear,

and maintain proper clearance on the floating side to allow free thermal expansion and smooth operation.

2. Interference Fit: Tight Isn’t Always Right – Managing Internal Clearance

Many engineers believe a tighter fit means better fixation.

However, excessive interference can compress the joint bearing’s internal clearance, leading to preload or even seizure.

In high-temperature or high-frequency oscillating environments, thermal expansion further worsens this effect.

QIBR Solution:

For applications requiring interference fits, choose joint bearings with C3 or C4 internal clearance.

These joint bearings are designed with slightly larger internal gaps to compensate for the effects of press-fitting and heat, ensuring smooth and reliable operation.

3.Real Case Study: A Small Fit Error, a Big Downtime Loss

A robotic arm on an automated production line experienced frequent jamming.

Inspection revealed the bearing’s outer ring had galled and fused with the housing.

The root cause? The floating support used an m6 shaft fit instead of the correct h6, locking the bearing axially.

As the shaft expanded from heat, stress built up, causing excessive temperature rise and lubrication failure.

Lesson Learned:

Even high-precision joint bearings can fail rapidly if the fit is wrong.

Always distinguish between fixed and floating supports — and never use a tight fit on the floating end.

4.A Systematic Approach: From Single Parameter to Full Reliability

At QIBR, we view fit selection as part of a system-level design strategy, not just a tolerance number.

- Engineers should evaluate:

- Load magnitude and direction

- Support type (fixed or floating)

- Oscillation frequency and angle

- Operating temperature and lubrication conditions

Only by integrating all these factors can you truly achieve the optimal tolerance match for maximum equipment stability and lifespan.

With QIBR’s extensive expertise and precision manufacturing capabilities, we provide comprehensive technical support — from joint bearings selection to assembly — helping our customers achieve longer service life, smoother motion, and easier maintenance.

QIBR — Engineered for Precision Motion.

Smart fit selection starts with the right tolerance.