Newsroom

QIBR T01-00675PAA Bearing: The Invisible Cornerstone of Precision Machinery

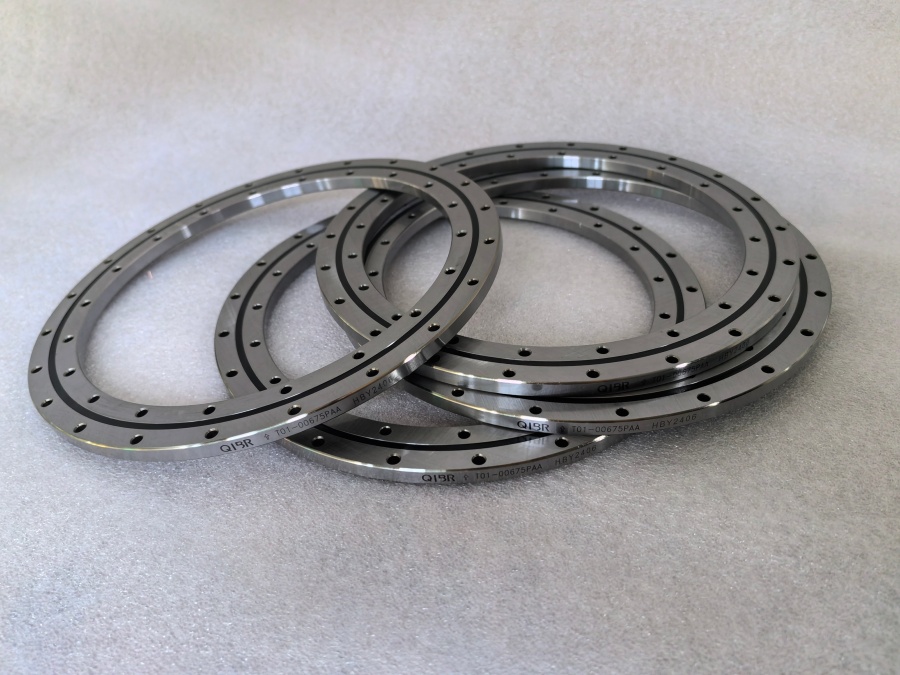

In the realm of high-end manufacturing, even minute deviations can lead to the failure of entire systems. Against this backdrop, the T01-00675PAA bearing from QIBR’s iconic REALI-SLIM TT series emerges as a paragon of precision in slewing bearings. It is providing critical support to sectors such as industrial automation, aerospace, and medical equipment. Its unassuming size belies its role as a linchpin in sustaining the accuracy and reliability of advanced machinery.

Understanding the T01-00675PAA: Series, Model, and Core Design

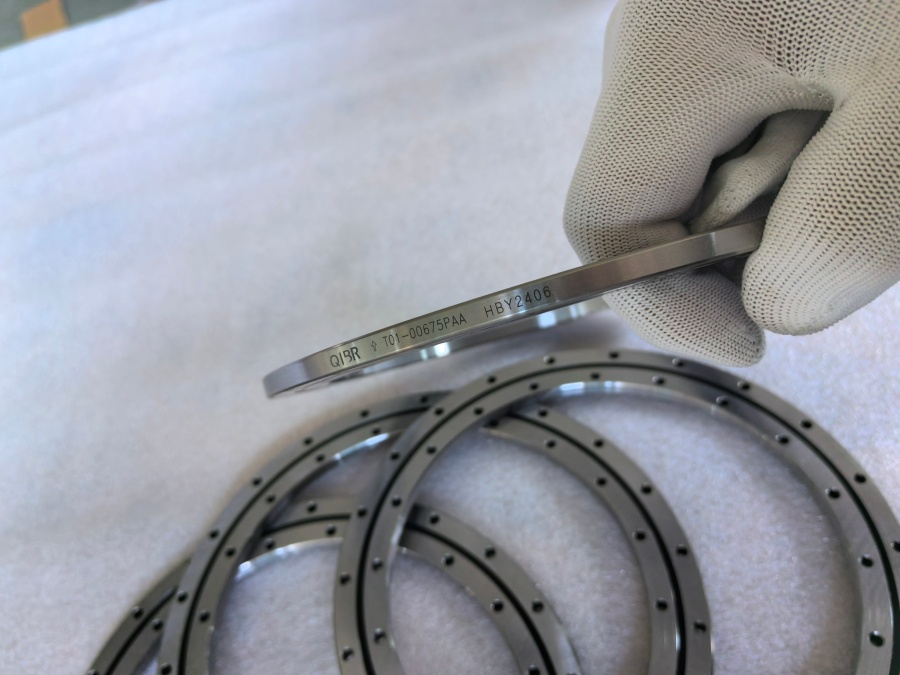

The T01-00675PAA belongs to QIBR’s thin-section bearing lineup—a category renowned for its ability to balance compactness with performance. To decode its model, industry conventions suggest that “T01” identifies the base product series, laying the groundwork for its structural design; “00675” specifies key dimensional parameters (such as inner/outer diameter or width), which dictate its compatibility with specific equipment; and “PAA” likely denotes critical performance attributes, such as precision class or sealing configuration. This coding system aligns it with counterparts like the T01-00675NAA, hinting at shared foundational designs while distinguishing its unique functional traits.

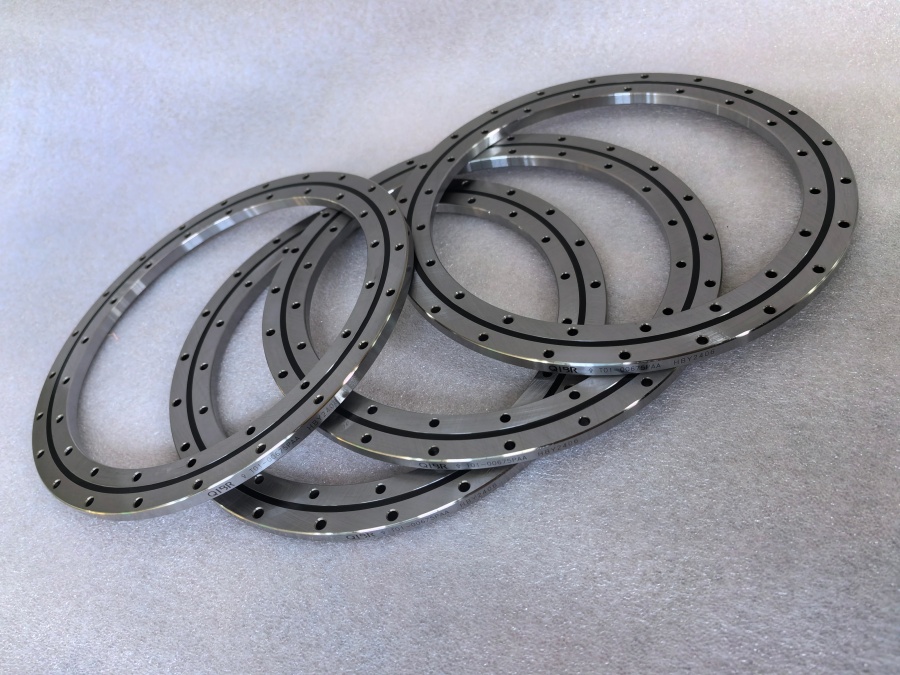

The defining feature of thin-section bearings like the T01-00675PAA is their small ratio of outer diameter to inner diameter. This design allows them to fit into space-constrained environments— a critical advantage in modern machinery, where miniaturization and integration are paramount. Unlike bulkier traditional bearings, it occupies minimal space while still delivering robust load-bearing capacity, making it indispensable for equipment where every millimeter of design real estate matters.

Core Competitiveness: Internal Preload Technology

What truly sets the T01-00675PAA apart is its advanced internal preload technology— a innovation that directly addresses the limitations of conventional bearings. Traditional bearings often suffer from “clearance” (the gap between rolling elements and raceways), which causes vibration, positioning errors, and reduced stability when operating at high speeds or under variable loads. The T01-00675PAA eliminates this flaw by using balls slightly larger than the natural clearance of the raceways, creating a “zero clearance” or even “negative clearance” state.

When external loads are applied, the balls and raceways undergo controlled elastic deformation, distributing contact stress evenly across the bearing’s interior. This not only boosts the system’s overall rigidity but also tightens control over positioning accuracy. In practical terms, this means the T01-00675PAA can maintain repeat positioning accuracy at the micron level— a requirement for high-precision applications like CNC machining or satellite antenna alignment, where even a fraction of a millimeter of error could render results useless.

Application Scenarios: Versatility Across High-Tech Sectors

The T01-00675PAA’s combination of compact design and precision performance makes it adaptable to a wide range of high-stakes scenarios.

In CNC turntables— a core component of machining centers— the bearing ensures the worktable rotates smoothly at high speeds, preventing wobble that would compromise the precision of cutting or milling operations. This directly translates to higher-quality finished parts and reduced waste.

In aerospace and satellite communications, it is used in antenna pedestals, where it must withstand complex loads (including axial, radial, and moment loads) while maintaining the antenna’s precise pointing angle. For satellite ground stations or radar systems, this stability is critical for receiving or transmitting signals without interference.

In medical equipment, particularly CT scanners, the T01-00675PAA balances two conflicting demands: high rotational precision and low noise. CT scanners require rapid, smooth rotation of the gantry to capture clear cross-sectional images, and the bearing’s design ensures patients are not disturbed by excessive noise while also guaranteeing image clarity.

Beyond these, its thin-section structure makes it ideal for robotic joints (where space is limited but movement must be precise) and semiconductor manufacturing equipment (where even tiny vibrations can disrupt chip production).

Materials, Manufacturing, and Quality Assurance

While QIBR does not publicly disclose the full material specifications of the T01-00675PAA, industry standards for high-precision bearings offer clues. It likely uses high-purity bearing steel, which undergoes specialized heat treatment to enhance hardness, wear resistance, and fatigue strength— critical for withstanding long-term, high-intensity operation.

The manufacturing process further elevates its performance. Precision grinding techniques ensure the raceways and balls have ultra-low surface roughness, minimizing friction and heat generation during operation. Reduced friction not only extends the bearing’s service life but also lowers energy consumption— a key consideration for modern, energy-efficient machinery.

Quality control is another cornerstone of the T01-00675PAA’s reliability. QIBR adheres to strict international standards such as ISO 9001, and its bearings undergo rigorous testing (including load capacity, rotational accuracy, and durability tests) before leaving the factory. This ensures consistent performance across every unit, a necessity for industries where equipment failure can lead to costly downtime or safety risks.

Installation, Maintenance, and Post-Sales Support

To fully leverage the T01-00675PAA’s capabilities, proper installation and maintenance are essential.

During installation, specialized tools must be used to ensure precise tolerance matching between the bearing, the housing bore, and the shaft. Overly tight or loose fits can disrupt the preload effect, reducing accuracy or causing premature wear. Technicians must also avoid applying excessive force to the bearing’s raceways, as this can damage the precision-ground surfaces.

Lubrication is another critical factor. The choice of lubricant (grease or oil) depends on the operating speed, temperature, and environment. Regular lubricant replacement prevents dry friction, which can lead to overheating and bearing failure.

In addition, users should monitor the bearing’s operating conditions— including temperature, vibration, and noise. Abnormal changes (such as a sudden rise in temperature or increased vibration) can indicate issues like insufficient lubrication or misalignment, allowing for timely maintenance to avoid catastrophic failure.

Suppliers like Shoushang Transmission also play a key role here, offering technical support such as installation guidance and maintenance training. This “sales + service” model ensures that users can maximize the bearing’s lifespan and performance, reflecting the holistic approach to high-end industrial product support.

Industry Significance and the Future of Precision Bearings

The T01-00675PAA is more than just a component—it reflects the broader trends shaping the precision bearing industry. As Industry 4.0 accelerates, machinery demands higher levels of accuracy, speed, and intelligence. Traditional bearings, with their inherent clearance and bulkier design, can no longer meet these needs, creating a growing demand for customized, high-precision solutions like the T01-00675PAA.

It also exemplifies the value of “hidden champions” in the manufacturing ecosystem. While the T01-00675PAA is not a household name, it is indispensable to the operation of high-tech equipment. Its role highlights how small, specialized components can drive the efficiency and innovation of entire industries.

For China’s manufacturing sector, the T01-00675PAA serves as both a benchmark and a challenge. China is a global leader in mid-to-low-end bearing production, but the high-end market remains dominated by imports from companies like QIBR. Studying the T01-00675PAA’s preload design, material technology, and manufacturing processes can provide valuable insights for domestic enterprises seeking to break into the high-end market and achieve import substitution.

Conclusion

The QIBR T01-00675PAA bearing may be small in size, but it is a giant in the world of precision manufacturing. Its combination of thin-section design, internal preload technology, and rigorous quality control makes it an invisible cornerstone of advanced machinery, supporting critical sectors from aerospace to healthcare. As the demand for precision and efficiency continues to grow, components like the T01-00675PAA will only become more important— driving innovation and setting new standards for what modern bearings can achieve. In the end, it is these small, precise components that enable the big leaps in manufacturing technology that define our era.