Newsroom

Reinventing Industrial Maintenance: The Growing Adoption of Split Bearing Units

As global industries accelerate toward high-efficiency and low-downtime production, Split Bearing Units are rapidly emerging as a preferred solution for equipment that demands easy maintenance, reduced shutdown time, and reliable operation under heavy loads. Designed with a separable structure that allows the housing and bearing to split into two halves, these units significantly simplify installation and replacement in large, complex or hard-to-access machinery.

Today, Split Bearing Units are becoming increasingly essential in industries such as mining, steel mills, cement processing, power generation, paper machinery, and long conveyor systems—sectors where bearing failures can lead to costly production stops.

Why Split Bearing Units Are Reshaping Maintenance Strategy

Traditional bearing replacement often requires the shaft to be fully removed, a process that can take hours—sometimes days—especially on large industrial drives. Split bearing units change this completely.

1. Easy Installation Without Shaft Removal

The two-piece housing and split inner ring allow maintenance teams to replace the bearing directly on the shaft, dramatically cutting downtime.

2. Ideal for Difficult-to-Access Locations

Whether mounted on elevated conveyors, enclosed housings, or long transmission shafts, split units reduce the need for heavy equipment disassembly.

3. Enhanced Load Capacity & Long Service Life

Modern split bearing units use:

- High-strength housings

- Optimized roller geometry

- Upgraded sealing systems

- High-performance lubricants

This provides excellent resistance to vibration, shock load, and contamination.

4. Reduced Total Cost of Ownership

Although the upfront cost is higher than standard units, the cost savings from reduced downtime and extended service intervals make split bearings extremely cost-effective.

A Closer Look at How Split Units Work

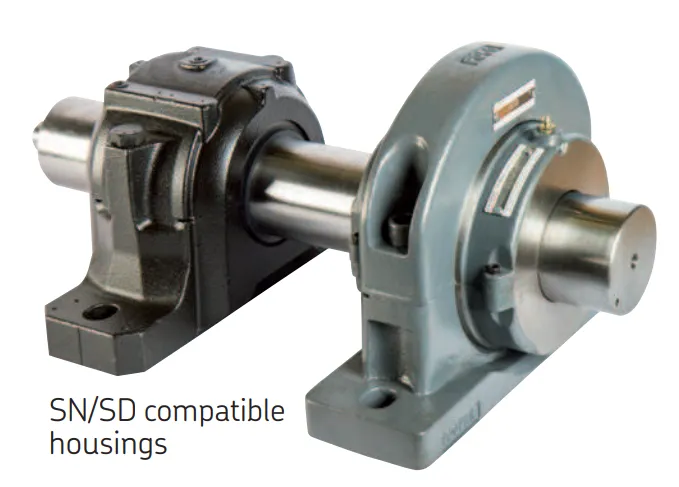

Split bearing units typically include:

- A two-piece housing (top and bottom)

- A split roller bearing (inner ring, outer ring, and cage are separable)

- Seals, locating rings, and lubrication paths

Once assembled around the shaft, the unit provides the same load performance as conventional bearings, while offering unmatched convenience.

This design makes split bearing units valuable in applications such as:

- Conveyor head pulleys

- Fan and blower shafts

- Crushers

- Industrial gearboxes

- Paper converting machines

- Large mixers and drying drums

QIBR's Technical Strength in Split Bearing Units

QIBR has expanded its product line to include high-precision split cylindrical roller bearing units and split spherical roller bearing units, engineered for the most demanding industrial environments.

Key design advantages include:

- High-precision split bearing rings to ensure smooth rotation

- Optimized cage design for improved load distribution

- Enhanced seals for dust- and moisture-heavy environments

- Interchangeable components for flexible replacement

- Housing options in cast iron, ductile iron, and steel

This ensures that QIBR's split units are capable of handling:

- High radial loads

- Moderate axial loads

- Misalignment compensation

- Continuous, high-stress operation

Supporting the Future of Predictive & Preventive Maintenance

As factories move toward predictive maintenance and digital monitoring, equipment reliability becomes more critical than ever. Split bearing units align perfectly with this trend by enabling faster maintenance intervals and minimizing unplanned downtime.

With industries demanding smarter, safer, and more efficient solutions, split bearing units are poised to become a mainstream choice for heavy-duty rotating equipment.

QIBR will continue to support global customers with advanced, durable, and easy-to-maintain bearing technologies—ensuring every operation runs with confidence and continuity.