Newsroom

Spherical Roller Thrust Bearings: A Reliable Solution for Heavy-Duty Industrial Applications

2018-01-16In the demanding world of industrial applications—where high loads, misalignments, and harsh environments are common—reliable bearing solutions are vital to ensure equipment stability and longevity. Spherical Roller Thrust Bearings have become a key choice in industries such as mining, metallurgy, cement, and power generation.

What Are Spherical Roller Thrust Bearings?

These bearings consist of:

- Raceways with spherical profiles

- Spherical rollers that maintain optimal contact

- A cage to ensure stable spacing of rollers

Their design allows them to accommodate:

- High axial load

- Moderate radial loads

- Self-alignment, even under shaft deflection or housing misalignmentStructural Features and Advantages

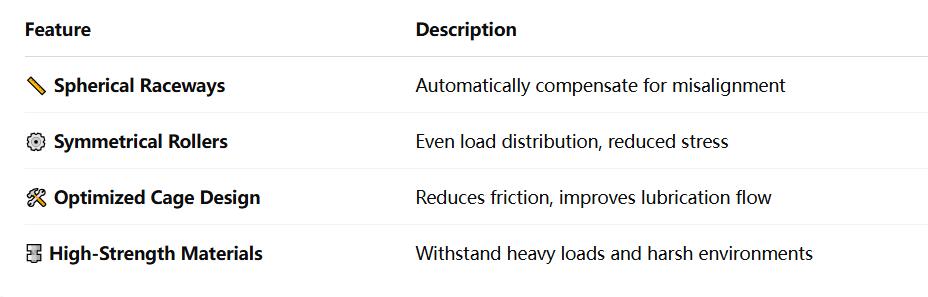

Structural Features and Advantages

These bearings provide:

- Superior shock resistance

- Excellent load-carrying capacity

- Reliable operation even under vibration and misalignment

Application Scenarios

- Mining Equipment (e.g., conveyors, crushers)

- Metallurgical Machinery (e.g., rolling mills, converters)

- Cement Industry (e.g., rotary kilns, clinker coolers)

- Power Generation (e.g., hydro turbines, gearboxes)

- Heavy-Duty Transmissions (e.g., gear reducers)

How to Select the Right Bearing

When selecting a spherical roller thrust bearing, consider:

-

Load Ratings – both axial and radial

-

Speed Limits – varies with size and lubrication

-

Mounting Conditions – including shaft/housing tolerances

-

Lubrication Method – grease or oil based on temperature and speed

-

Material Options – stainless steel, ceramic rollers for special environments

Maintenance and Best Practices

- To maximize performance and service life:

- Ensure proper lubrication and regular inspection

- Monitor for temperature rises or unusual vibration

- Avoid contamination with dust, water, or metal particles

- Use correct installation tools to prevent ring deformation

Why Choose Us?

At Luoyang QIBR Precision Bearing Co., Ltd., we manufacture high-precision spherical roller thrust bearings using:

- Deep cryogenic treatment for dimensional stability

- High-purity bearing steel with fatigue strength of 600–800 MPa

- P2 and P4-grade accuracy for critical applications

- Surface-treated components for corrosion and wear resistance.