Newsroom

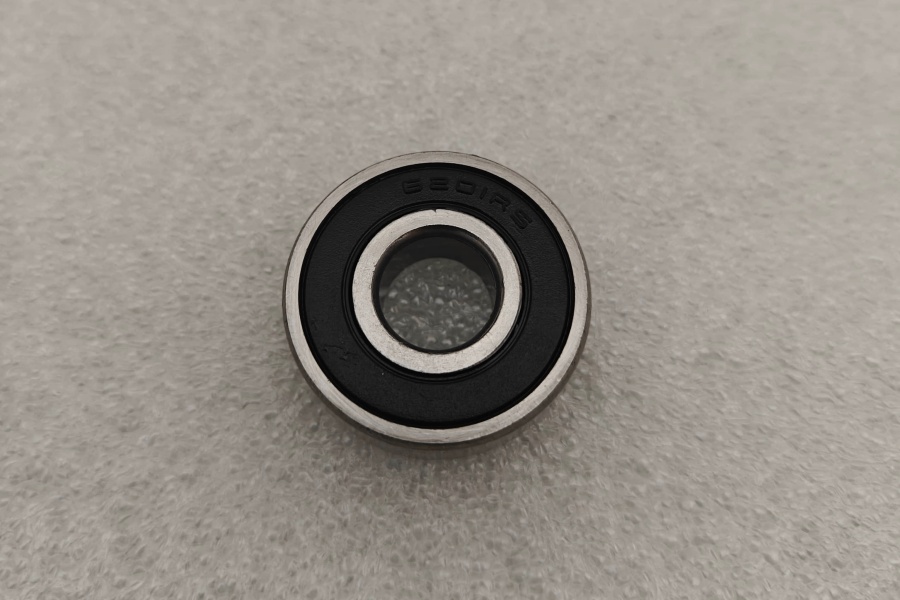

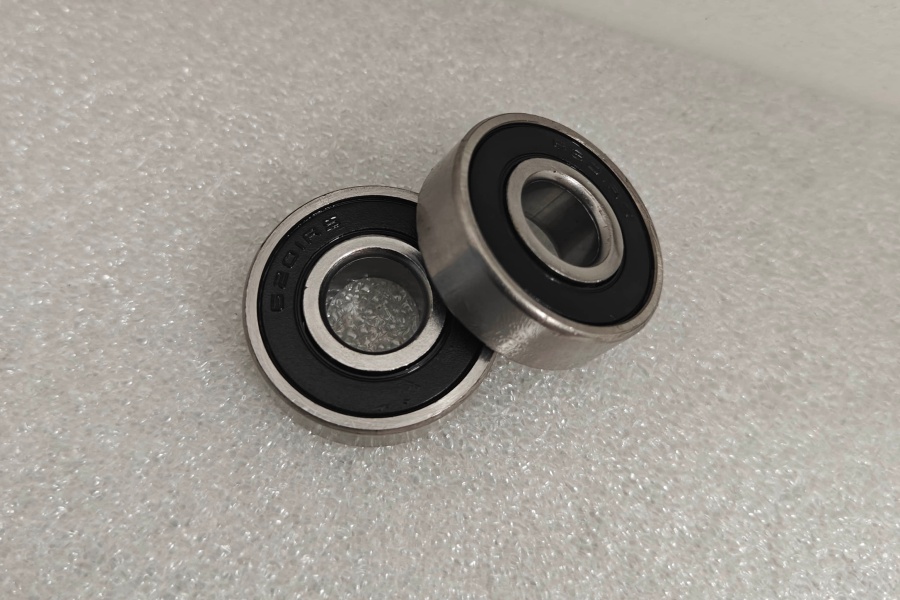

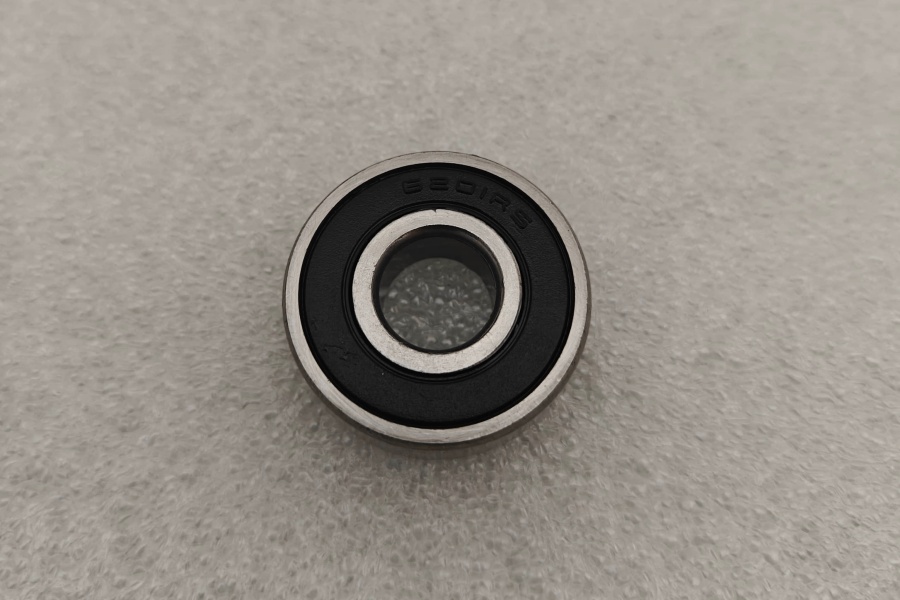

The 6201 2RS Bearing: A Compact, Reliable Component for Mechanical Systems

Bearings are essential to modern machinery, enabling smooth rotation, reducing friction, and supporting loads in everything from household appliances to industrial tools. Among these, the 6201 2RS stands out as a versatile, cost-effective option in the deep groove ball bearing family. Its compact size, sealed design, and consistent performance make it a top choice for engineers, technicians, and hobbyists. This article breaks down its key features, applications, and care guidelines to highlight why it remains a staple in small-scale mechanical systems.

1. Decoding the 6201 2RS Nomenclature

The bearing’s name is not random—it follows international standards (e.g., ISO 15:1998) to communicate critical details:

6: Identifies it as a deep groove ball bearing, the most widely used type, capable of handling radial loads (perpendicular to the shaft) and light axial loads (parallel to the shaft).

2: Indicates the “light” dimension series, balancing load capacity and compactness—ideal for space-constrained applications.

01: The inner diameter (ID) code. For most deep groove ball bearings, ID = code × 5 mm, so this translates to a 5 mm ID, perfect for small shafts.

2RS: Signifies dual rubber seals (one on each side). These seals use nitrile butadiene rubber (NBR) with steel reinforcement to block contaminants (dust, moisture) and retain lubricating grease.

2. Core Design and Components

The 6201 2RS’s reliability comes from its precision-machined parts, each serving a specific role:

Inner Ring: Fits tightly on the rotating shaft, with a grooved raceway that guides the rolling elements. It rotates with the shaft and distributes loads evenly.

Outer Ring: Sits in the stationary bearing housing, with a matching inner raceway. It provides a stable surface for the rolling elements to move against.

Rolling Elements: Typically 7–8 spherical balls made of high-carbon chromium steel (GCr15/AISI 52100). These convert sliding friction to rolling friction, cutting energy loss by up to 90%.

Cage: Separates the balls to prevent collisions. Made of low-carbon steel (for strength) or nylon 66 (for quiet, low-friction operation), it ensures smooth rotation.

2RS Seals: The defining feature—flexible NBR lips contact the inner ring to seal out debris and retain grease. Unlike open bearings (needing frequent re-lubrication) or shielded bearings (limited protection), 2RS seals extend maintenance intervals.

3. Materials: Strength and Durability

Materials are chosen to withstand friction, wear, and environmental stress:

Rings & Balls: GCr15 (AISI 52100) high-carbon chromium steel offers high hardness (HRC 60–65), excellent fatigue strength (resisting cracks over millions of cycles), and basic corrosion resistance (with proper lubrication). For harsh environments (e.g., marine use), stainless steel variants (AISI 440C) are available.

Seals: Standard NBR works for -30°C to 100°C, ideal for most household and industrial uses. For high-temperature applications (e.g., automotive engine bays), fluoroelastomer (FKM) seals (withstanding up to 200°C) are an option.

Cage: Steel cages suit high-load/high-speed uses (e.g., power tools), while nylon 66 cages are lighter, quieter, and cheaper for low-to-medium loads (e.g., appliances).

4. Key Performance Traits

The 6201 2RS balances performance and practicality for small systems:

Load Capacity: Designed for radial loads—its basic dynamic load rating (C) is ~5.1 kN (sustained load at moderate speeds), and static load rating (C₀) is ~2.3 kN. It handles light axial loads (~10% of radial load) but not heavy thrust forces (use thrust bearings for those).

Rotational Speed: With grease (most common), it reaches ~18,000 rpm; with oil lubrication (high-speed needs), up to ~24,000 rpm—perfect for small motors and tools.

Friction & Noise: Low friction (from rolling elements and precision raceways) saves energy, critical for battery-powered devices. Seals and plastic cages keep noise below 50 dB (quiet office level), ideal for appliances.

Service Life: Under good care, it lasts over 10,000 hours (a year of continuous use) at 10,000 rpm and 1 kN load—reducing downtime and replacement costs.

5. Common Applications

Its compact size and sealed design make it useful across industries:

Household Appliances: Washing machine drum motors (resisting water/detergent), AC/fan motors (dust-proof), and refrigerator condenser fans (cool, dry environments).

Electric Tools: Cordless drills/screwdrivers (handling torque, keeping out sawdust) and angle grinders (high-speed, moderate-load use).

Automotive: Auxiliary motors (windshield wipers, power windows, HVAC blowers) and scooter/motorcycle starter motors (vibration-resistant).

Medical/Office Equipment: Blood pressure monitor rotating parts (precision) and printer/copier motors (paper dust protection).

6. Installation & Maintenance Tips

Proper care maximizes lifespan:

Installation: Clean shaft/housing/bearing (no debris); use a press/sleeve (not a hammer) to avoid damage; ensure slight interference fit for the inner ring (prevents slipping) and clearance for the outer ring (thermal expansion). Align shaft/housing (0.1 mm misalignment increases friction).

Maintenance: It comes pre-lubricated—re-lubricate every 5,000–10,000 hours with lithium grease (general use) or polyurea grease (high temperatures). Inspect seals every 6 months for cracks (replace if damaged). Monitor temperature: normal operation is 30–50°C above ambient; over 80°C means overloading, poor lubrication, or misalignment.

7. Troubleshooting Common Issues

Even with care, problems may arise—here’s how to fix them:

Abnormal Noise: Caused by contamination, low lubrication, or damaged parts. Clean and re-lubricate; if noise persists, replace the bearing.

Overheating: From overloading, misalignment, or too much grease. Reduce load, realign components, or remove excess grease.

Premature Wear: Due to contamination, misalignment, or low-quality grease. Replace seals, clean parts, realign, and use high-grade grease.

Seizure: Severe contamination, no lubrication, or overheating. Replace the bearing and fix the root cause (e.g., improve lubrication).

8. Conclusion

The 6201 2RS proves that simple, well-engineered components are the backbone of mechanical systems. Its compact size, sealed protection, and balanced performance make it indispensable for small-scale applications, from home appliances to industrial tools. As technology demands smaller, quieter, more efficient devices, manufacturers may upgrade its materials (e.g., better corrosion resistance) or seals, but its role as a reliable, cost-effective workhorse will remain. By following installation and maintenance guidelines, users can ensure it delivers long, trouble-free service.