Newsroom

The Adaptation Temperature and Working Environment of Slewing Bearings

2024-09-12The Adaptation Temperature and Working Environment of Slewing Bearings

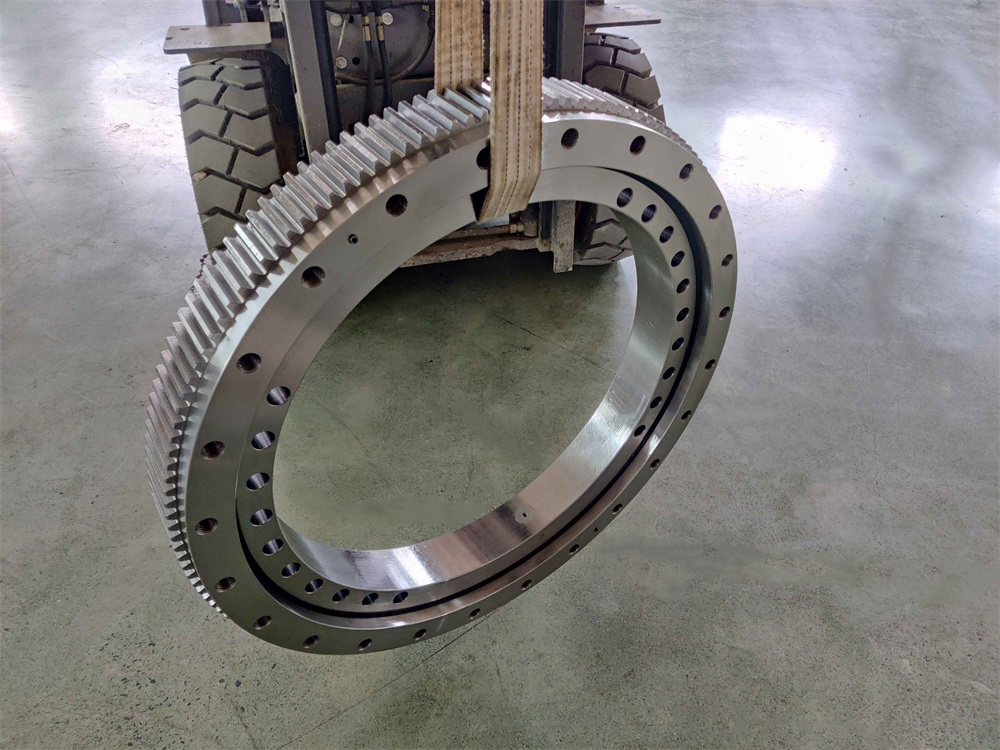

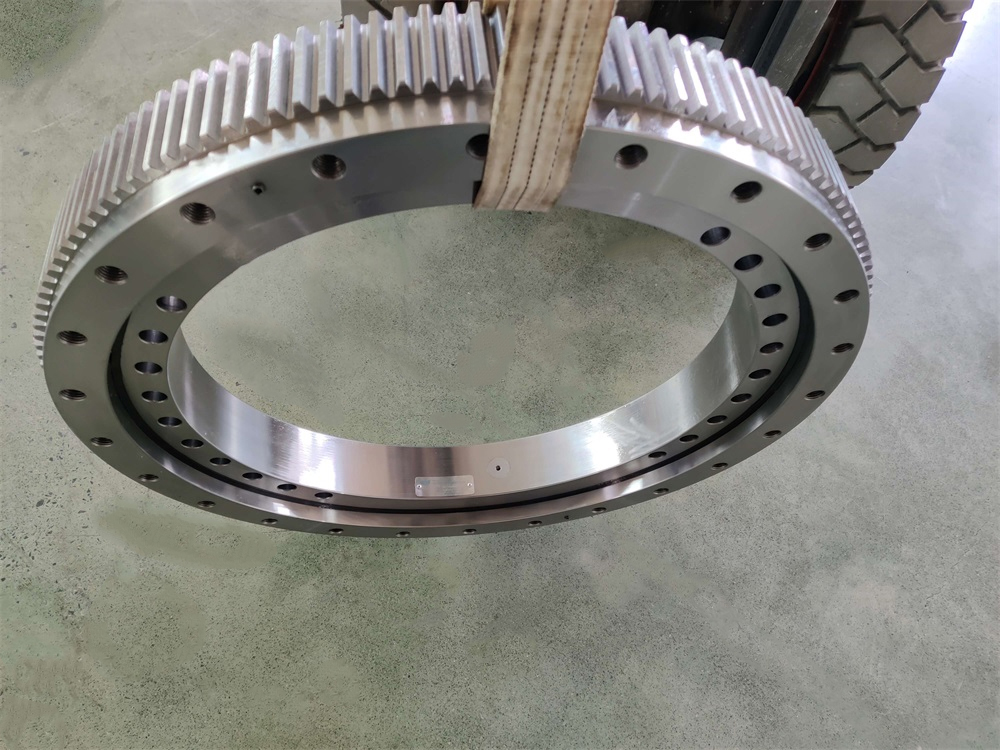

Slewing bearings, known as the "joints" of machines in the mechanical industry, enable relative rotational movement between two objects. They are crucial transmission components that can withstand axial forces, radial forces, and overturning moments. What are the adaptation temperature and working environment for slewing bearings?

1. Heat Treatment of Slewing Bearing Tracks and Gears

The performance of slewing bearings is closely related to the heat treatment processes used during manufacturing. Firstly, the rolling tracks of slewing bearings are typically treated with surface induction hardening to ensure a hardness level of HRC55-62. This achieves sufficient hardened layer depth, enhancing wear resistance and extending service life.

Moreover, due to the need for force transmission, one of the rings in the slewing bearing is usually equipped with teeth. The heat treatment state of the gears is generally normalized or quenched. The tooth surface can also be quenched according to user requirements, with a hardness range of HRC50-60, ensuring adequate depth. Depending on different application scenarios, gear hardening can be classified into full-tooth hardening and single-tooth induction hardening. Single-tooth induction hardening can further be divided into tooth face and tooth root hardening, as well as face hardening only. These heat treatment processes ensure stability and reliability under high load conditions.

2. Adaptation Temperature Range of Slewing Bearings

The working temperature range of slewing bearings is a crucial indicator for evaluating their performance. Generally, standard slewing bearings can operate normally in temperatures ranging from -30°C to +70°C. This temperature range is suitable for most common industrial applications. However, in certain special cases where users require slewing bearings to operate at lower or higher temperatures, manufacturers can typically provide custom designs to meet specific needs.

For instance, in extremely cold or hot environments, the physical properties of materials may change, affecting the performance of slewing bearings. Therefore, selecting appropriate materials and designs is critical for equipment operating under these extreme conditions.

3. Impact of Working Environment on Slewing Bearings

In addition to temperature, the working environment also significantly affects the performance of slewing bearings. In particularly harsh environments—such as marine climates, dust-laden areas, abrasive particles, sandstorms, cement dust, and coal dust—slewing bearings may suffer damage. In such cases, additional protective measures are necessary to ensure normal equipment operation.

1).Special Seals

When used in harsh environments, it is advisable to select specially designed seals. These seals effectively prevent dust, moisture, and other contaminants from entering the internal components, thereby protecting the rolling elements and raceways from damage.

2).Protective Equipment

In addition to seals, extra protective equipment such as dust covers or waterproof covers can be considered to further enhance protection. These measures can significantly extend the service life of slewing bearings and reduce maintenance frequency.

3).Appropriate Lubricants

Lubricating oil is essential for maintaining the normal operation of slewing bearings. In harsh environments, it is important to choose lubricating oils suitable for those specific conditions to ensure effective lubrication and prevent failures due to wear.

4).Daily Maintenance and Care

To ensure that slewing bearings operate stably over long periods, daily maintenance and care are essential. Users should regularly check the condition of lubricating oil and promptly replace any oil that has aged or become heavily contaminated. Additionally, regular cleaning of seals and protective devices is necessary to avoid accumulation of dust and debris that could impair equipment performance.

In summary, understanding the adaptation temperature and working environment of slewing bearings is crucial for selecting and maintaining mechanical equipment effectively. Through proper design choices, material selection, and regular maintenance practices, users can enhance the performance of slewing bearings under various operating conditions—ensuring efficient and safe operation of machinery.