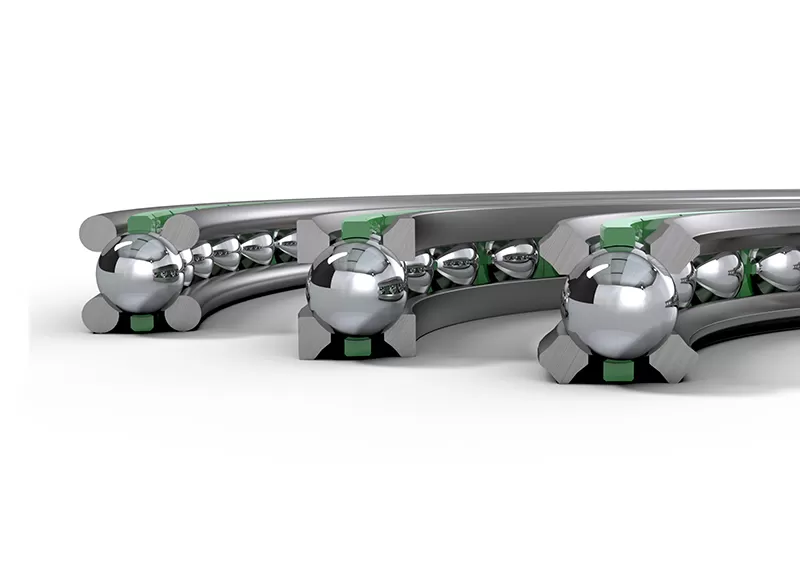

The composition of a wire race bearings typically includes the inner ring, outer ring, wire raceway, rolling elements, cage, elastic pad, etc. The specific introduction is as follows:

- Function: They are the main supporting structures of the wire race bearings. The inner ring is usually matched with the shaft and rotates with it, while the outer ring is installed in the bearing housing or other fixed components to support and position, allowing the rolling elements to roll between the inner and outer rings and bear/transfer loads.

- Material: Generally made of low-carbon steel, which is stress-relieved annealed and then machined to obtain good strength and toughness for the bearing's service requirements.

- Function: It is the track for rolling elements to roll. Processed by precision CNC, it features high accuracy and low friction torque, showing strong adaptability to high-speed working conditions. It can increase the number of steel balls, effectively improving overall machining accuracy, starting friction performance, and load-carrying capacity.

- Material: Usually made of materials like DIN 54SiCr6 (similar to 60Si2CrA spring steel). Quenching and tempering can achieve ideal hardness and toughness.

- Function: They are the key components for the wire race bearings to achieve rolling motion. Rolling between the wire raceways, they reduce friction between the inner and outer rings, enabling the bearing to operate smoothly and bear the loads transmitted by the inner and outer rings.

- Material: Generally GCr15 steel balls, which have high hardness, strength, and wear resistance, ensuring stable operation under high-speed and high-load conditions.

- Function: Used to isolate and guide rolling elements, making them evenly distributed between the inner and outer rings to prevent collisions and friction among rolling elements, ensuring the bearing runs smoothly. It also helps maintain the correct position and movement trajectory of rolling elements.

- Material: Commonly made of polyamide (nylon) PA-11 or PA-12, etc., with good wear resistance, self-lubrication, and corrosion resistance to maintain stable performance during bearing operation.

- Function: Installed between the wire raceway and the inner ring, it can absorb vibrations and shocks, reduce noise and vibration during bearing operation, and meet the equipment requirements for stable operation and low noise.

- Function: Installed between the outer wire raceway and the corresponding corner of the outer ring groove, it further reduces the vibration noise value during bearing operation, improving the stability and reliability of the bearing.

- Function: A channel set on the inner ring, corresponding to and connected with the outer ring groove. Lubricating grease can be added to the steel balls through this channel for lubrication and protection, reducing friction between rolling elements and raceways and extending the bearing's service life.