Newsroom

The Reliable Guardian in Industrial “Heat Fields” — High-Temperature Deep Groove Ball Bearings

2025-07-04In the vast landscape of industrial production, high-temperature environments resemble a “blazing battlefield,” posing intense challenges for mechanical equipment. Imagine a steel mill, where roaring furnaces raise the ambient temperature to several hundred degrees Celsius, or a glass manufacturing plant where raw materials melt into molten liquid under extreme heat. Equipment in these environments must operate continuously while enduring severe thermal stress. In such demanding conditions, high-temperature deep groove ball bearings emerge as reliable heroes, offering new solutions for ensuring the stable operation of machinery under extreme heat.

1.Exceptional Heat Resistance: From 120°C to Over 500°C:

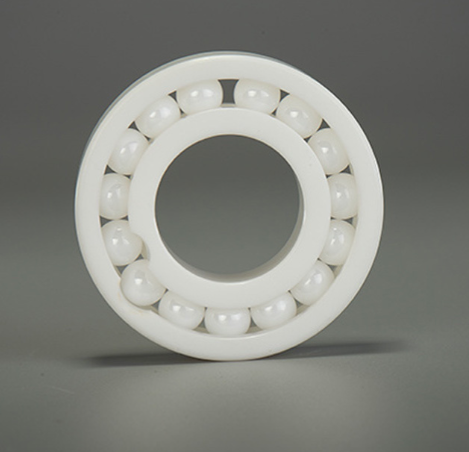

Ordinary deep groove ball bearings typically function properly below 120°C. However, high-temperature deep groove ball bearings are crafted from specially engineered heat-resistant materials—such as high-temperature alloy steels and silicon nitride ceramics—and undergo advanced heat treatment processes, enabling them to withstand temperatures ranging from 300°C to 500°C, or even higher.

For example, a high-performance bearing from QIBR brand utilizes high-temperature alloy steel, which, after specialized forging and heat treatment, maintains stable dimensional accuracy and mechanical performance even under 500°C, ensuring reliable operation.

2.Outstanding Load Capacity: Reliable Under Heat and Pressure

High-temperature deep groove ball bearings are not only heat-resistant—they also offer excellent load-bearing capabilities. Their internal structure is optimized for better load distribution, with improved contact areas and stress dispersion between the rolling elements and raceways.

In the steel industry’s continuous casting machines, bearings must withstand both extreme temperatures and the immense radial loads of heavy steel billets. Data shows that a specific model of high-temperature deep groove ball bearing can operate steadily under 5 tons of radial load at 300°C, outperforming standard bearings by 2 to 3 times in load capacity.

3.Long Service Life & Low Maintenance: A Cost-Saving Asset

The extended service life of high-temperature deep groove ball bearings comes from their high-quality materials and precise manufacturing processes. These materials are highly resistant to wear and fatigue, minimizing damage under stress. Precision machining ensures smoother rolling movement, reducing friction and extending bearing life.

For example, in a chemical plant’s high-temperature reactor system, switching from standard bearings to high-temperature deep groove ball bearings extended the maintenance interval from 3 months to 1 year, significantly reducing downtime and maintenance costs while enhancing production efficiency.

4.Practical Care Guidelines

A. Proper Installation: The Foundation of Stable Operation

Proper installation is the first and most critical step in ensuring optimal bearing performance—much like laying a solid foundation for a skyscraper.

- Cleanliness First: Ensure the working environment is clean and dust-free. Remove any contaminants that could damage the bearing.

- Inspection Before Installation: Check for visible damage (scratches, dents) and verify that shaft and housing dimensions and surface finishes meet specifications.

- Installation Methods: For light interference fits: Use the press-fit method. Apply even pressure using a press machine, ensuring the force is applied to the bearing ring and never transmitted through rolling elements.

- For tight interference fits: Use the thermal mounting method. Heat the bearing to 80°C–100°C for thermal expansion, then quickly mount it onto the shaft. Temperature control is essential to prevent damage. Once cooled, the bearing will form a secure fit with the shaft.

B. Proper Lubrication: Lifeline Under Extreme Heat

Effective lubrication is critical for bearing longevity, especially in high-temperature environments where standard greases fail. Specialized high-temperature lubricants such as synthetic greases or perfluoropolyether-based (PFPE) greases are recommended for their thermal stability, oxidation resistance, and anti-wear properties.

- Lubrication Schedule: Adjust based on operating conditions. High-temperature, heavy-load, or high-speed applications require shorter intervals.

- Routine Inspection: Check grease condition regularly. If the lubricant appears dry, discolored, hardened, or contaminated, replace it immediately.

- Performance Monitoring: Abnormal noise or vibration may indicate poor lubrication or other issues.

C. Real-Time Monitoring & Preventive Maintenance

Continuous monitoring is vital to ensure stable bearing operation:

- Temperature Monitoring: Use infrared thermometers to check bearing temperature. An unexpected rise may indicate poor lubrication, excessive load, or improper installation. Stop and inspect as needed.

- Vibration & Noise Monitoring: Use vibration analyzers or stethoscopes. Increased or irregular noise and vibration often signal wear, fatigue, or looseness.

- Fault Handling: Minor Issues: Can be resolved through reinstallation, re-lubrication, or minor repairs.

- Severe Failures: Such as damaged cages or worn raceways, require immediate bearing replacement to prevent further equipment damage.

5.Conclusion: A Silent Guardian in High-Temperature Industries

In heat-intensive sectors like steelmaking, glass manufacturing, and chemical processing, high-temperature deep groove ball bearings serve as more than just a component—they are a solution. With exceptional thermal tolerance, load-bearing capacity, and long service life, they ensure stable equipment performance and reduce maintenance costs.

As industries evolve and operational challenges intensify, these bearings will continue to serve as silent guardians, safeguarding machines in the most extreme conditions and enabling uninterrupted productivity.

For more information, feel free to contact QIBR