Newsroom

Thin-Section Ball Bearings: Reshaping Performance of Excavator Core Components, Unlocking New Possibilities for Heavy Loads with "Constant Section"

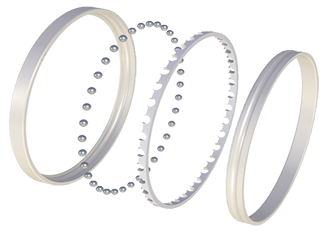

2025-06-30  As the main force in construction machinery, excavators operate under harsh conditions for a long time, and the reliability of their core components directly affects work efficiency. Thin-section ball bearing, with their advantages of "constant section, lightweight, and high rigidity", have become a key upgrade component for excavator slewing platforms and travel mechanisms.

As the main force in construction machinery, excavators operate under harsh conditions for a long time, and the reliability of their core components directly affects work efficiency. Thin-section ball bearing, with their advantages of "constant section, lightweight, and high rigidity", have become a key upgrade component for excavator slewing platforms and travel mechanisms.

I. Core Advantages of Thin-Section Ball Bearings

(1) Constant Section, High Space Utilization

When the inner and outer diameters change, the section thickness remains constant, breaking the limitation of traditional bearings where "section thickness increases with size growth". For example, when the inner diameter increases from 100mm to 300mm, the section thickness of traditional bearings rises from 15mm to 35mm, while that of thin-section ball bearing still maintains 12-15mm. This reserves more space for internal components of excavators and reduces the volume of components by 20%-25%.

(2) Lightweight & High Rigidity, Reduced Energy Consumption

Made of high-strength alloy steel, they are 25%-30% lighter than traditional bearings of the same size, with radial rigidity increased by 10%-12%. Lightweight design reduces motion inertia and equipment load; high rigidity resists alternating impact loads of 50-100kN, extending continuous operation time.

(3) High Precision & Strong Sealing, Adaptable to Harsh Conditions

Manufacturing precision reaches Grade P5 (radial runout ≤ 0.015mm), ensuring the positioning accuracy of the slewing platform within ±0.5°; sealing performance meets IP65 or higher, preventing dust and muddy water from entering. Their service life is 8,000-10,000 hours, far exceeding the average 6,000 hours of traditional bearings. Additionally, they feature flexible installation methods, reducing maintenance difficulty.

II. Applications in Excavator Core Components

(1) Slewing Platform: Stable & Accurate

The slewing platform bears composite loads, and traditional bearings tend to cause jamming and deviation. For 20-30 ton excavators (e.g., Sany SY215), K-series section thin-section ball bearing (e.g., K80×95×7) are adopted. With a section thickness of 7mm, they can bear 120kN radial load and 80kN axial load, shortening start-up response time to 0.8 seconds and improving positioning accuracy from ±1° to ±0.8°.

(2) Travel Mechanism: Low Resistance & Durable

The travel mechanism operates on rough roads, and traditional bearings are prone to wear. For 15-ton excavators (e.g., XCMG XE150D), RNA-series section thin-section ball bearing (e.g., RNA60×72×12) are used. With a section thickness of 12mm, they save 33% space compared to traditional bearings, have a friction coefficient of 0.0015, and reduce motion resistance by 25%. Wear loss per 1,000 hours decreases from 0.12mm to 0.05mm, and service life extends to 12,000 hours.

(3) Boom Joint: Low Maintenance

Boom joints swing frequently and bear 80-120kN digging force, while traditional copper bushings require frequent maintenance. Liugong CLG920E uses the 51120X thrust-type thin-section ball bearing, with a section thickness of 20mm and integrated self-lubrication. The maintenance cycle extends from 3,000 hours to 8,000 hours, single replacement cost decreases by 37.5%, and annual maintenance cost is reduced by 40%.

III. Technological Iterations Adapting to Industry Trends

(1) Material Innovation: Resistant to Extreme Conditions

QIBR Bearing manufactures thin-section ball bearing using maraging steel (18Ni-300), which has a tensile strength of 2,000MPa and works stably at 150℃. Applied to XCMG XE700 mining excavators in 2024, after 600 hours of heavy-load operation, the fatigue damage rate of these bearings is only 1/3 of that of traditional bearings, with an expected service life of 15,000 hours (30% longer).

(2) Process Upgrade: High Precision & Stability

By introducing 5-axis CNC grinding machines and automated production lines, the grinding precision of section thin-section ball bearings is ≤0.005mm, and the roundness error of rolling elements is ≤0.002mm. Full coverage of laser inspection increases the qualification rate from 98% to 99.8%, and the radial runout standard deviation of K-series section thin-section ball bearings decreases by 27%, ensuring assembly accuracy.

IV. Industry Value & Conclusion

Thin-section ball bearings drive the upgrading of the excavator industry by reducing costs (20%-25% lower life-cycle costs), improving efficiency (15%-20% higher daily operation volume), and reducing emissions (15% lower carbon emissions, 10% longer electric battery life). In the future, QIBR Bearing will continue R&D efforts on thin-section ball bearing to help the industry break through bottlenecks and achieve efficient and low-carbon development.

Made of high-strength alloy steel, they are 25%-30% lighter than traditional bearings of the same size, with radial rigidity increased by 10%-12%. Lightweight design reduces motion inertia and equipment load; high rigidity resists alternating impact loads of 50-100kN, extending continuous operation time.