Newsroom

Using hearing to identify irregular operation of tapered roller bearing

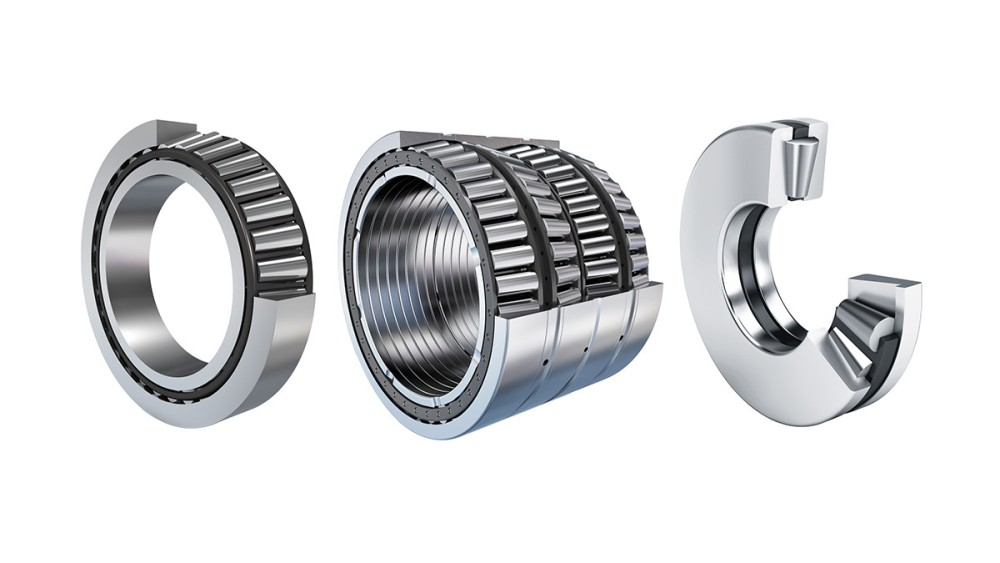

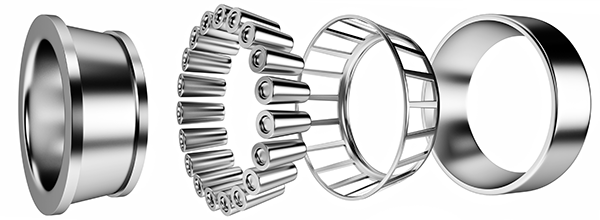

2025-05-23When handling taper roller bearing, sweat on hands can cause rust. It is crucial to operate with clean hands and wear gloves as much as possible. Identifying irregular operation of tapered roller bearing by hearing is a common method. For example, experienced operators use electronic stethoscopes to detect abnormal noises from specific components. A tapered roller bearing in good condition emits a low humming sound, while sharp hissing, squeaking, or other irregular noises typically indicate poor operation.

1. Tapered roller bearing Pad Corrosion

- Spectral analysis reveals abnormal concentrations of non-ferrous metal elements.

- Ferrography shows submicron-sized wear particles with many non-ferrous metal components.

- Lubricating oil has excessive moisture or acid value.

2. Journal Surface Scuffing

- Ferrography contains iron-based cutting abrasives or black oxide particles.

- Temper colors exist on the metal surface.

3. Journal Surface Corrosion

- Spectral analysis shows abnormal iron element concentration.

- Ferrography includes numerous submicron particles of iron components.

- Lubricating oil has excessive moisture or acid value.

4. Surface Scuffing

- Ferrography detects cutting abrasives with non-ferrous metal composition.

5. Backing Fretting Wear

- Spectral analysis indicates abnormal iron concentration.

- Ferrography shows many submicron wear particles of iron components.

- Lubricating oil has abnormal moisture and acid value.

Under liquid lubrication conditions, the sliding surfaces are separated by lubricating oil without direct contact, which can significantly reduce friction loss and surface wear. The oil film also has certain vibration absorption capacity.

Sharp squeaking noises may be caused by improper lubrication, while inappropriate bearing clearance can produce metallic sounds. Dents on the outer ring raceway of tapered roller bearings cause vibration and clear, crisp sounds. Noises from impact scars during installation vary with the bearing's rotational speed. Intermittent noises suggest possible damage to rolling elements—this sound occurs when the damaged surface is rolled over. Contaminants in the bearing often cause hissing, and severe bearing damage produces irregular and loud noises.

For more information, feel free to contact QIBR