Newsroom

What are Characteristics of the Slewing Bearing 010.20.200?

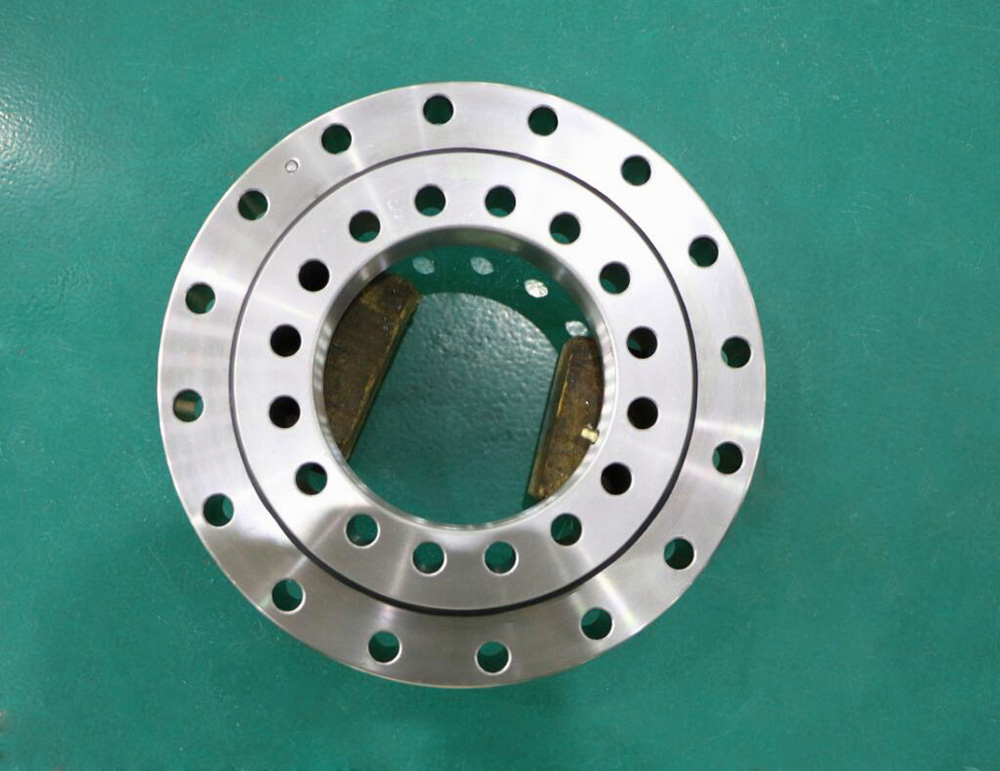

In the realm of precision engineering, slewing ring bearings represent critical components that enable rotational movement while handling combined loads. Among these mechanical workhorses, model 010.20.200 stands out as an engineering marvel - holding the distinction of being the smallest standardized slewing ring bearing in industrial applications. This article examines the technical specifications, applications, and unique advantages of this compact bearing solution.

1. Technical Specifications: Miniaturized Excellence

The 010.20.200 model embodies precision miniaturization with dimensions of:

- Bore diameter: 100 mm

- Outer diameter: 200 mm

- Height: 20 mm

These compact measurements make it 35% smaller than the next standard size in the series, while maintaining impressive load capacities:

- Axial static load: 12 kN

- Radial static load: 8 kN

- Dynamic moment: 1.8 kNm

The single-row four-point contact ball design ensures optimal stress distribution despite its reduced size. Manufactured from case-hardened 42CrMo4 steel, it achieves a Rockwell hardness of 58-62 HRC on raceways while maintaining core toughness. The bearing comes standard with ISO 492:2014 compliance and optional IP54 sealing for harsh environments.

2. Design Philosophy: Small Footprint, Big Performance

Engineers achieved this miniaturization breakthrough through:

- Micro-geometry optimization: Raceway curvatures refined to 52% of ball diameter for reduced stress concentration

- Precision grinding: Raceway surface roughness maintained at Ra 0.2μm

- Compact seal design: Integrated nitrile rubber seals at 3mm thickness

- Weight reduction: Hollow-bore construction cuts mass to 1.8kg without compromising strength

The bearing's 0.0025° backlash rating rivals larger counterparts, enabling precise positioning in automated systems. Its 90% space efficiency (active components vs. housing) sets new benchmarks for compact drive solutions.

3. Application Spectrum

The 010.20.200 finds critical roles in space-constrained applications:

- Medical robotics: Enables precise articulation in surgical arm joints

- Drone gimbals: Supports 360° camera rotation in UAVs under 5kg payload

- Miniature turntables: Powers compact assembly line indexers

- Solar trackers: Drives single-panel solar arrays in residential installations

- Laboratory equipment: Facilitates precision rotation in microscopy stages

A case study in semiconductor manufacturing demonstrates its value: Replacing traditional bearings with 010.20.200 models in wafer inspection robots reduced joint size by 40% while increasing positioning repeatability to ±0.005mm.

4. Comparative Advantages

When benchmarked against similar-sized custom bearings, the standardized 010.20.200 offers:

- 30% faster delivery times

- 65% cost reduction versus bespoke micro-bearings

- 85% improvement in replacement part availability

- Standardized mounting patterns compatible with DIN 6885

Maintenance data shows 50,000-hour MTBF (Mean Time Between Failures) under proper lubrication, matching the reliability of bearings twice its size.

5. Installation Considerations

While compact, proper installation remains crucial:

1. Mounting surface flatness: ≤0.05mm/m

2. Bolt preload: 20-25% of bolt yield strength

3. Lubrication: NLGI 2 grease with 3-month replenishment cycles

4. Alignment: Maximum 0.1° angular misalignment

The bearing's integrated lubrication grooves allow easy maintenance access - a critical feature in embedded applications.

6. Economic Impact

The standardization of 010.20.200 has revolutionized compact machinery design:

- Enables 15-20% size reduction in final products

- Reduces total drive system costs by 12-18%

- Cuts energy consumption through 8-10% lower inertia

- Facilitates modular designs with 25% fewer unique components

Industry analysts estimate this bearing family has enabled $240M in annual savings across precision engineering sectors since its standardization in 2018.

7. Future Developments

Emerging trends show:

- Growing demand in micro-mobility (e-scooter steering systems)

- Integration with IoT sensors for predictive maintenance

- Development of hybrid ceramic versions for vacuum environments

- 3D-printed customized variants maintaining standard interfaces

Manufacturers are exploring graphene-enhanced lubricants to push temperature limits beyond current -30°C to +120°C range.

Conclusion

The 010.20.200 slewing ring bearing exemplifies how miniaturization drives innovation. By packing robust performance into the smallest standardized footprint, it enables new generations of compact machinery while maintaining cost efficiency and reliability. As industries continue pursuing size reduction without performance compromises, this micro-bearing stands poised to remain an essential component in precision motion systems. Its development signals a broader trend towards "right-sized" components that maximize functionality within minimal spatial constraints - a philosophy reshaping modern mechanical design.