Newsroom

What are the Application Prospects of Slewing Bearings in the Wind Power Industry?

I. Overview of Slewing Bearings

Slewing bearings, as critical fundamental mechanical components, are widely used in various types of equipment requiring rotational motion. Characterized by robust structure and stable performance, they provide efficient rotational support in diverse environments. Unlike standard bearings, slewing bearings can withstand combined loads including axial, radial, and moment loads, making them indispensable in heavy-duty applications. Their design integrates gear teeth and mounting holes, facilitating direct connection to structural components and driven elements. The manufacturing process involves advanced heat treatment and precision machining to ensure durability and reliability. As a core component in rotational mechanisms, the performance of slewing bearings directly impacts the efficiency and service life of the entire equipment. With the advancement of industrial technology, the design and production of slewing bearings continue to evolve, meeting increasingly complex and demanding operational conditions.

II. The Relationship Between Wind Power Generation and Slewing Bearings

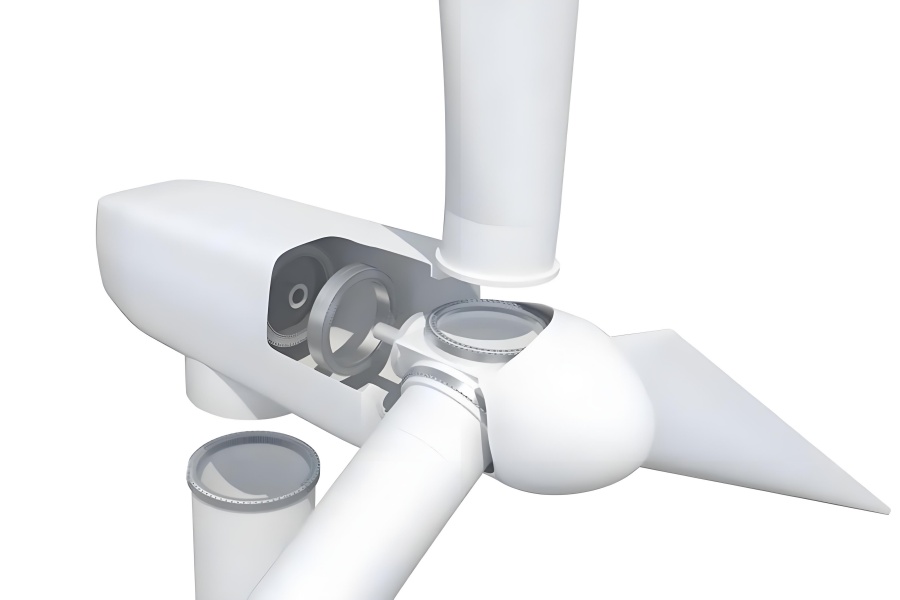

Wind power generation converts wind energy into mechanical energy via wind turbines, which then drive generators to produce electricity. In this process, the rotational support section of the wind turbine plays a crucial role. Slewing bearings, due to their unique rotational capabilities and stable performance, have become the ideal choice for wind power generation equipment. They are primarily installed in the yaw and pitch systems of wind turbines. The yaw system ensures the nacelle rotates to face the wind direction optimally, while the pitch system adjusts the blade angles to control power output and manage loads. The precision and reliability of slewing bearings directly determine the efficiency and safety of these systems. As wind turbines operate in harsh environments with variable winds, temperatures, and humidity, slewing bearings must exhibit exceptional wear resistance, corrosion resistance, and fatigue strength. Therefore, the quality and performance of slewing bearings are vital to the overall functionality of wind power systems.

III. Applications of Slewing Bearings in Wind Power Generation

In wind turbine systems, slewing bearings mainly provide rotational support for the wind turbine components. With the trend toward larger wind turbines, the demand for slewing bearings is continuously increasing. Modern multi-megawatt turbines require larger-diameter and higher-performance slewing bearings. These bearings not only support the substantial weight of the rotor and blades but also ensure smooth operation under various wind conditions, providing stable mechanical support for the power generation process. In the yaw system, slewing bearings enable the nacelle to rotate smoothly and accurately, tracking changes in wind direction. In the pitch system, they allow precise adjustment of blade angles to optimize energy capture and protect the turbine from potential damage during extreme weather conditions. The reliability of slewing bearings is critical to minimizing downtime and maintenance costs. As turbine designs advance, the integration of condition monitoring sensors directly into slewing bearings is becoming more common, enabling real-time performance tracking and predictive maintenance.

IV. Analysis of Application Prospects

Growing Market Demand: The global shift toward renewable energy and advancements in wind power technology are driving sustained growth in the demand for wind turbines. This, in turn, is propelling the expansion of the slewing bearing market. Government policies supporting clean energy and international commitments to reduce carbon emissions are further accelerating wind power project installations worldwide.

Driven by Technological Innovation: Progress in materials science and manufacturing processes, such as the use of high-grade steels advanced sealing technologies and improved heat treatment methods, is continuously enhancing the performance of slewing bearings. These innovations offer greater possibilities for the wind power industry, including extended service life, increased load capacity, and reduced maintenance needs.

Trend Towards Larger Wind Power Equipment: The development of larger-capacity wind turbines requires slewing bearings with larger dimensions, higher precision, and greater reliability. This trend presents significant market opportunities for slewing bearing manufacturers capable of producing these high-value, sophisticated components.

Coexistence of Challenges and Opportunities: Despite the promising market outlook, challenges such as wind energy intermittency, harsh operating environments, and high maintenance demands must be addressed. Through technological innovation—like developing more corrosion-resistant coatings or integrating smart monitoring systems—and optimized service models, slewing bearing manufacturers can better adapt to market needs and gain a competitive edge. Additionally, the growing aftermarket for replacement and repair services offers further business potential.

V. Conclusion

In summary, the application prospects of slewing bearings in the wind power industry are vast. As renewable energy becomes more prevalent and wind power technology continues to advance, the use of slewing bearings in this sector will become increasingly widespread. Manufacturers who focus on technological innovation, product quality, and providing excellent service will be well-positioned to capitalize on these market opportunities. By developing more reliable and efficient slewing bearings, they can contribute significantly to the growth and sustainability of the global wind power industry, supporting the world's transition to a cleaner energy future.