Newsroom

What are the characteristics of angular contact bearings?

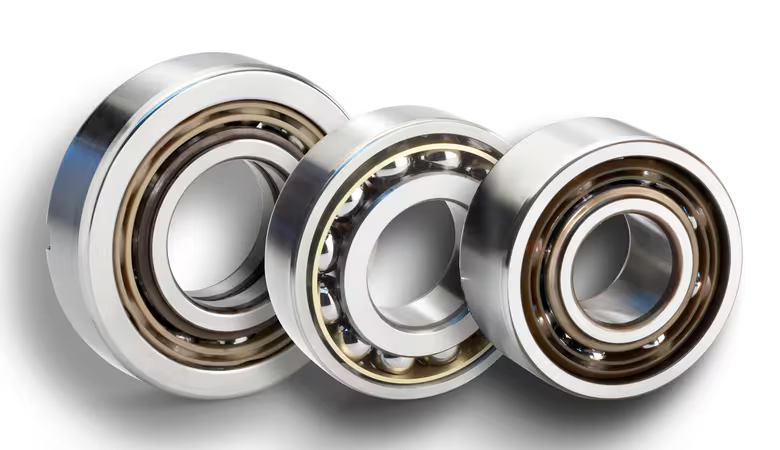

2018-12-18Angular contact bearings are a kind of bearing commonly used in the industrial field. So, what are the characteristics of angular contact bearings?

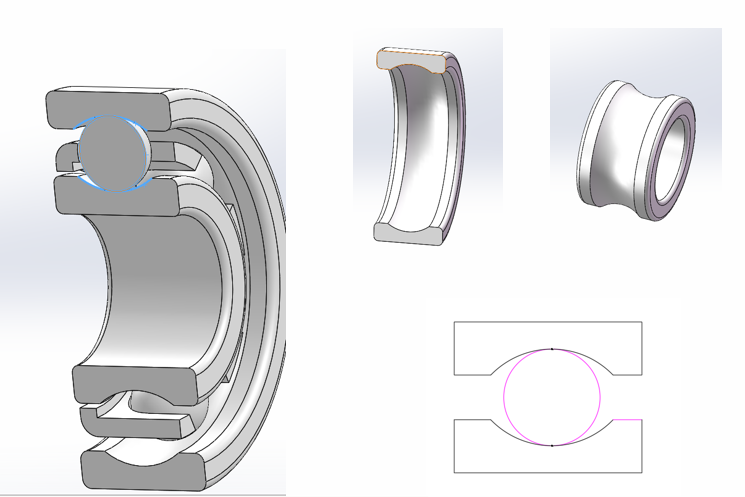

I. Structural Characteristics

1. Contact Angle:

There is a contact angle between the rolling elements of angular contact bearings and the raceways of the rings. The size of the contact angle determines the ability of the bearing to withstand axial and radial forces. Generally speaking, the larger the contact angle, the stronger the bearing's ability to withstand axial forces.

Common contact angles are 15°, 25°, 30°, and 40°, etc.

2. Rolling Elements:

Steel balls are usually used as rolling elements, which have high load-carrying capacity and rigidity.

The number and size of rolling elements are determined according to the specifications and design requirements of the bearing.

3. Cage:

The function of the cage is to separate the rolling elements, prevent the rolling elements from colliding and rubbing with each other, and guide the rolling elements to roll correctly on the raceway.

The materials of cages include metals, plastics, etc. Different materials have different performance characteristics.

II. Performance Characteristics

1. Load-Carrying Capacity:

Angular contact bearings can withstand both radial loads and axial loads, and have high comprehensive load-carrying capacity.

According to the size of the contact angle and the structural design of the bearing, the ratio of the axial force and radial force that the bearing can withstand can be adjusted.

2. Rotational Speed Performance:

Since the contact between the rolling elements and the raceway of the rings is point contact or line contact, and the friction coefficient is small, angular contact bearings have high rotational speed performance.

It can meet the requirements of high-speed rotating mechanical equipment.

3. Precision and Rigidity:

Angular contact bearings have high manufacturing precision and can ensure rotational precision and stability.

At the same time, due to its compact structure, it has high rigidity and can withstand large loads and impacts.

4. Installation and Adjustment:

Angular contact bearings usually need to be used in pairs. By adjusting the preload between the bearings, the rigidity and rotational precision of the bearings can be improved.

During installation, pay attention to the installation direction of the bearing and the fitting precision to ensure the normal operation of the bearing.

The usage methods of angular contact bearings are as follows:

I. Preparation before Installation

1. Check the Bearing:

Before installing angular contact bearings, check whether the appearance of the bearing has defects such as damage and rust.

Check whether the size of the bearing meets the requirements and ensure the fitting precision with the installation part.

2. Clean the Installation Part:

Clean the surface of the installation part to remove impurities such as oil stains and dust.

Cleaners or solvents can be used for cleaning, and then dry it with a clean cloth.

3. Prepare Installation Tools:

According to the size and installation requirements of the bearing, prepare appropriate installation tools such as sockets, wrenches, and presses.

II. Installation Process

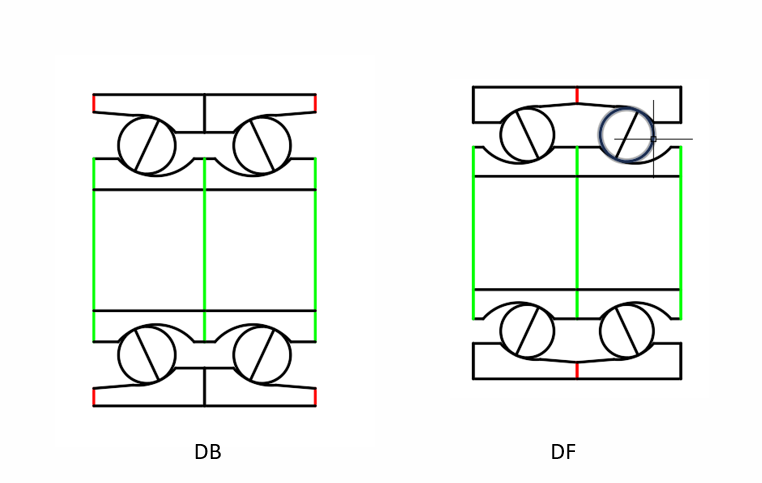

1. Pair Installation:

Angular contact bearings usually need to be used in pairs. During installation, install the two bearings back to back or face to face to withstand axial and radial forces.

Pay attention to the installation direction of the bearing during installation to ensure the correct direction of the contact angle.

2. Adjust the Preload:

After installation, it is necessary to adjust the preload between the bearings to improve the rigidity and rotational precision of the bearings.

The size of the preload can be determined by measuring the axial clearance of the bearing or using a special preload adjustment tool.

3. Fix the Bearing:

After adjusting the preload, the bearing should be fixed on the installation part to prevent the bearing from displacing during operation.

Fixing parts such as bolts, nuts, and locating pins can be used for fixation.

III. Use and Maintenance

1. Lubrication:

Angular contact bearings need to be lubricated during use to reduce friction and wear and extend the service life of the bearing.

According to the use conditions and requirements of the bearing, select an appropriate lubrication method and lubricant.

2. Operation Monitoring:

During the operation of the bearing, regularly monitor parameters such as the temperature, vibration, and noise of the bearing to judge whether the operation state of the bearing is normal.

If abnormal conditions are found, stop the machine in time for inspection, find out the cause and deal with it.

3. Maintenance:

Regularly maintain the bearing, including cleaning, lubrication, inspection, etc.

If the bearing is found to be damaged or severely worn, it should be replaced in time.

Precise torque, stable spindle! QIBR has been focusing on the production of precision machine tool for over 20 years!