Newsroom

What are the key points for selecting thin-section bearings?

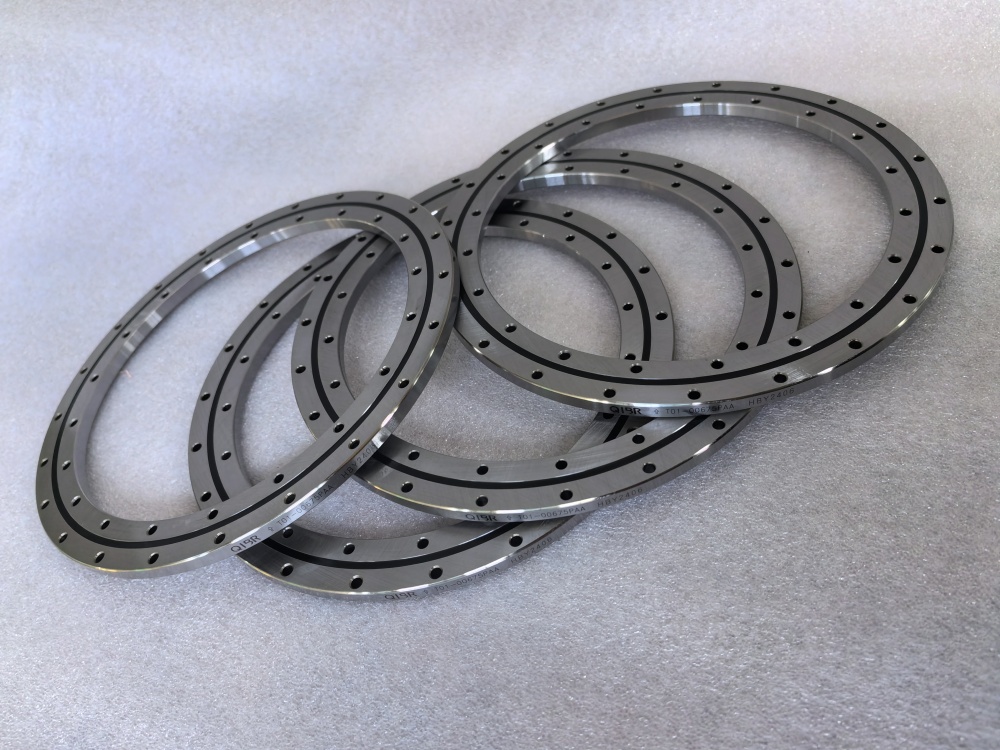

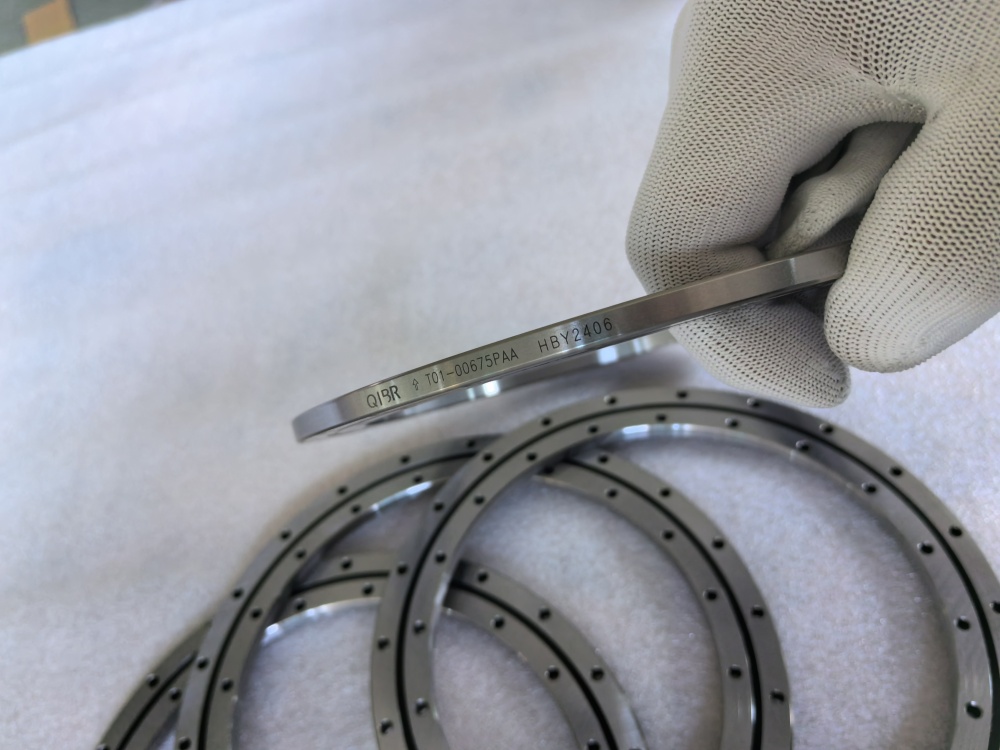

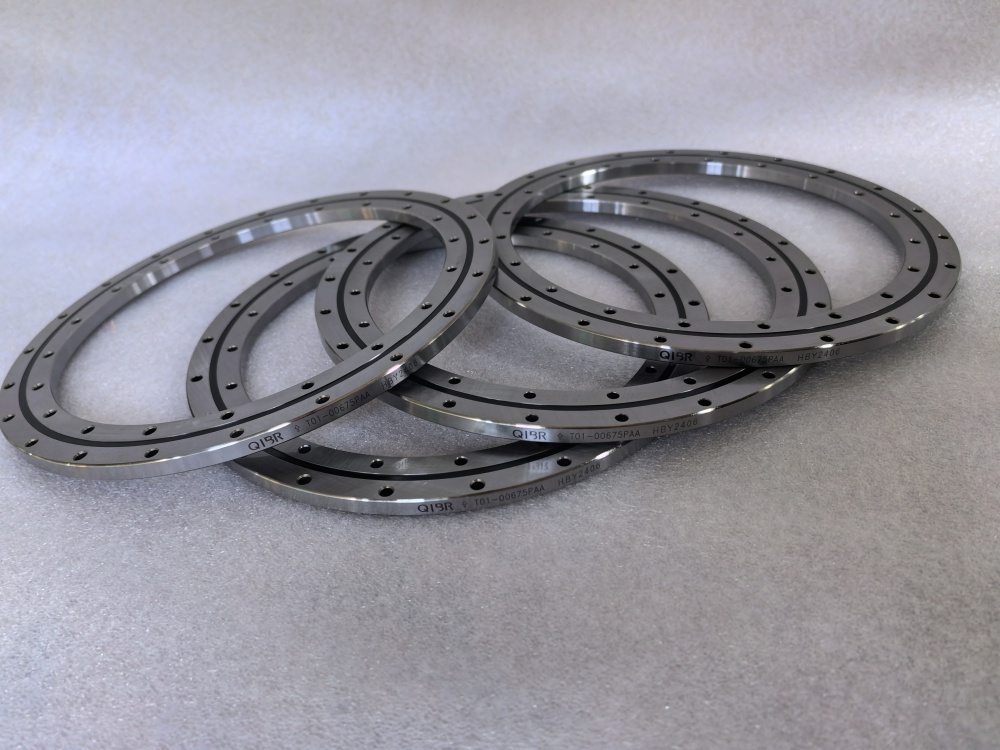

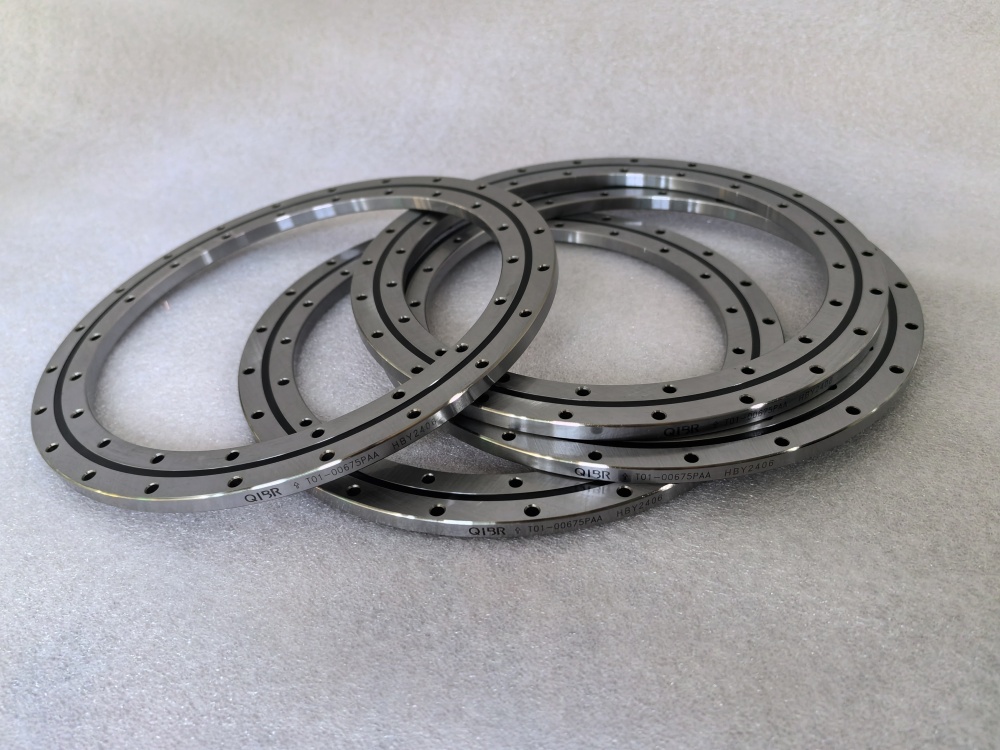

Selection points of thin-section bearings

In order to obtain low friction torque, high rigidity and good rotation accuracy of thin-section bearings, small outer diameter steel balls and hollow shafts are used to ensure light weight and wiring space. Thin-section bearings achieve thin bearing sections and also achieve miniaturization and lightweight of products. The diversity of products expands its application range.

Main reasons for heat treatment deformation of thin-section bearings:

One of the main reasons for deformation of thin-section bearings is the uneven expansion and contraction of the bearing surface and interior during heat treatment and cooling, as well as the thermal stress and large microstructural stress generated by different microstructural transformations. When the ring undergoes overall plastic deformation, the deformation manifests as expansion or contraction in the diameter direction; when local plastic deformation occurs, the roundness or cylindricity error becomes larger. Due to the fast cooling rate of quenching oil, which far exceeds the heating rate of the ring in the heating furnace, and the poor stiffness of the thin-section bearing ring, most of the deformation occurs during the cooling process.

There are many factors that affect the heat treatment deformation of thin-section bearing rings. Any method that can reduce thermal stress and structural stress during heat treatment can reduce the deformation of the ring. From the perspective of heat treatment process, lowering the quenching temperature, properly controlling the holding time, increasing the quenching oil temperature, and reducing the stirring speed of the quenching oil can effectively reduce the deformation of the ring. Due to the poor rigidity of the thin-section bearing ring with a large outer diameter, it may deform under certain thermal stress and structural stress during the heat treatment process. Therefore, in order to control its deformation, it is necessary to formulate a suitable heat treatment process to control thermal stress and microstructural stress.

The original heat treatment process of thin-section bearings is: quenching temperature 855. Heating time 30min quenching oil temperature is 100. After a set of lathes, add appropriate stress relief annealing; in the quenching stage, properly control the quenching heating temperature and reasonably control the quenching cooling speed; before quenching, use water glass, asbestos rope or refractory clay to block the oil circuit; heating in a protective atmosphere can reduce oil tank cracking. Improving the structure or shape of the oil tank, avoiding straight oil tank and horn effect, will also play a role in controlling oil tank cracks.

Whether the thin-section bearing can be selected correctly will have good working performance and extend the service life of the main machine. It plays a very important role in shortening maintenance time, reducing maintenance costs and improving machine operation rate. Therefore, both design and manufacturing units and maintenance and use units must attach great importance to the selection of thin-section bearings.

Generally speaking, the steps for selecting thin-section bearings can be summarized as follows:

1. According to the working conditions of the bearing, including load direction and load type, speed, lubrication method, coaxiality requirements, positioning or non-positioning, installation and maintenance environment, ambient temperature, etc. Select the basic type, tolerance grade and clearance of thin-section bearings;

2. According to the working conditions, stress conditions and service life requirements of thin-section bearings, determine the bearing type by calculation, or select the bearing type according to the use requirements, and then check the service life;

3. Check the rated load of the selected bearing. The main factors to consider when selecting thin-section bearings are the required life and load capacity. Other factors help determine the type, structure, size, tolerance level and clearance requirements of thin-section bearings.