Newsroom

What are the main application areas of insulated bearings?

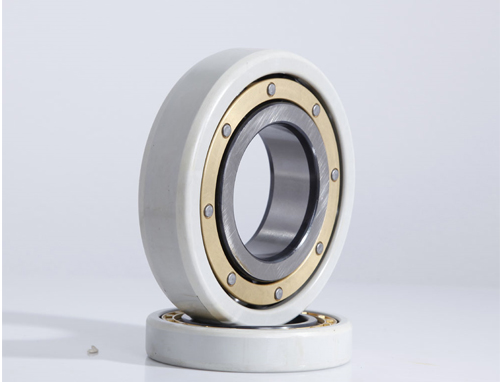

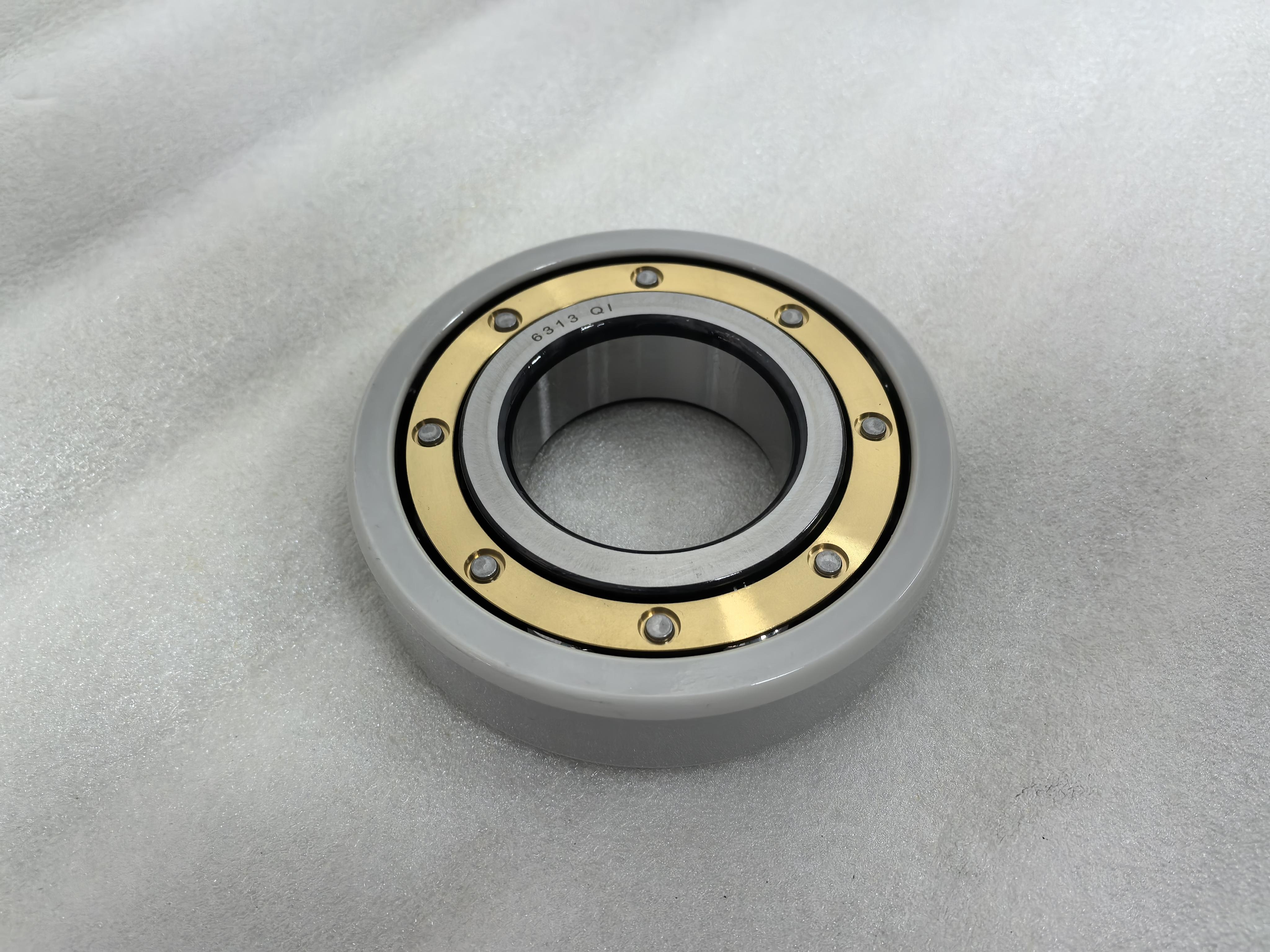

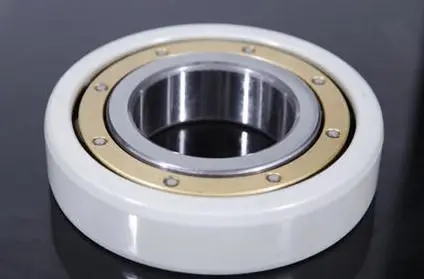

2024-11-22Insulated bearings are a type of bearing with excellent insulation properties, widely applied across various industries. Below are the primary application areas:

1.Power Industry:

Insulated bearings have a particularly prominent role in the power industry. They are extensively used in generators, wind turbines, hydroelectric generators, and thermal power generators. These bearings prevent electrical corrosion caused by induced currents, shielding lubricants and rolling elements from electrical damage, thereby extending the bearing’s service life.

2.Railway Infrastructure

Insulated bearings also play a crucial role in the railway sector, especially in equipment like traction motors for diesel locomotives. These bearings effectively prevent electrical damage to ensure the safety and stable operation of railway systems.

3.Machinery and Metallurgy Industry

Insulated bearings are widely applied in cranes, textile machinery, printing machinery, ironmaking equipment, steelmaking equipment, rolling mills, cutting machines, coking equipment, and smelting systems. These machines often operate under high power and voltage conditions. Insulated bearings prevent electrical damage to ensure normal operations.

4.Mining Machinery Industry

Insulated bearings are vital in mining equipment like coal preparation machines, coal washing machines, crushers, ball mills, grinders, and sand mills. They prevent electrical damage to bearings and maintain the stability of the equipment’s operation.

5.Petrochemical Industry

Insulated bearings are also critical in high-power explosion-proof motors, particularly in compressors and similar equipment.

Thanks to their unique structure and excellent performance, insulated bearings are widely used in numerous industries and fields. Looking ahead, as technology advances and new applications emerge, the prospects for insulated bearings will become even broader. Additionally, ensuring the quality and performance of insulated bearings requires coating inspections and specialized evaluation standards and testing methods, which are essential steps in their production and application.

For more information, feel free to contact QIBR