Newsroom

What are the types of industrial robot bearings?

2023-08-02Industrial robots play a crucial role in the field of smart manufacturing by efficiently performing tasks such as rotation, handling, and movement. Different types of industrial robots require different types of bearings to meet their operational needs.

Here are some common types of bearings used in industrial robots:

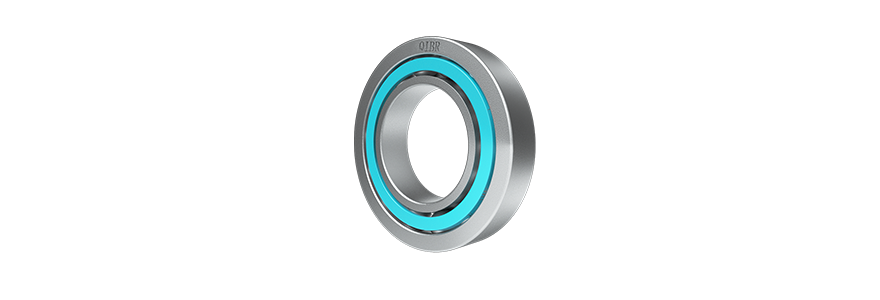

1. Angular Contact Ball Bearings: Representing high precision and high-speed bearings, these are used in precision robots, measuring instruments, and similar equipment. They offer characteristics such as high load capacity, high speed, and good rigidity. Common series include the 70 series, 72 series, 73 series, 79 series, and 78 series.

2. Deep Groove Ball Bearings: Known for their simple structure, large load capacity, high speed, and good wear resistance, these bearings are used in transmission parts of industrial robots. Common series include the 60 series and 62 series.

3. Tapered Roller Bearings: Primarily used in heavy-load motion parts of industrial robots, these bearings offer high load capacity and strong rigidity. They are suitable for high-speed rotation and complex impact load conditions. Common series include the 32 series and 303 series.

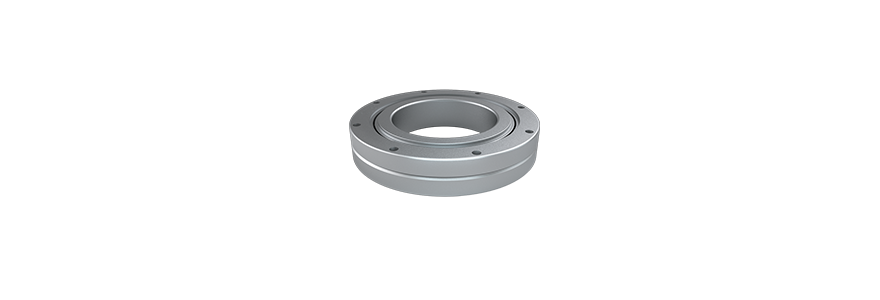

4. Crossed Roller Bearings: These special bearings feature segmented outer and inner rings and can withstand radial loads, axial loads, and moment loads from multiple directions. They are stable and commonly used in robot joints and rotating parts.

When selecting bearings for industrial robots, it's important to consider:

- Load Capacity: Robots on production lines experience varying torque and load requirements, necessitating the selection of bearings that can handle these demands.

- Speed Requirements: Bearings must be chosen based on the operational speed of the industrial robot to ensure they meet the production line's needs.

- Environmental Factors: The material and operating temperature of bearings are crucial to their performance in different working environments, ensuring reliable operation.

In summary, choosing the right bearings involves matching their capabilities to the specific operational demands of industrial robots, thereby optimizing performance and reliability in manufacturing processes.