Newsroom

What is insulation bearings?

2024-10-11Insulated Bearings are a special type of bearing designed to prevent electrical current from passing through them. They are widely used in motors, generators, and other high-load, high-frequency rotating equipment. The main purpose of insulated bearings is to prevent electrical corrosion that occurs when current flows through the bearing, thereby protecting the bearing and extending the service life of the equipment.

In modern industrial equipment, electrical corrosion has become a common and serious problem, especially in motors driven by frequency converters. When a motor is running, it often generates shaft voltage. This current may flow through the bearing circuit to ground, leading to the formation of electrical arcs between the rolling elements and raceways of the bearing. Even tiny electrical arcs can cause localized heating on the bearing surface, resulting in pitting, flaking, and ultimately premature bearing failure. Insulated bearings add an insulating layer to the inner or outer ring or rolling elements of the bearing, effectively preventing the passage of current and fundamentally eliminating electrical corrosion.

1.Working Principle of Insulated Bearings

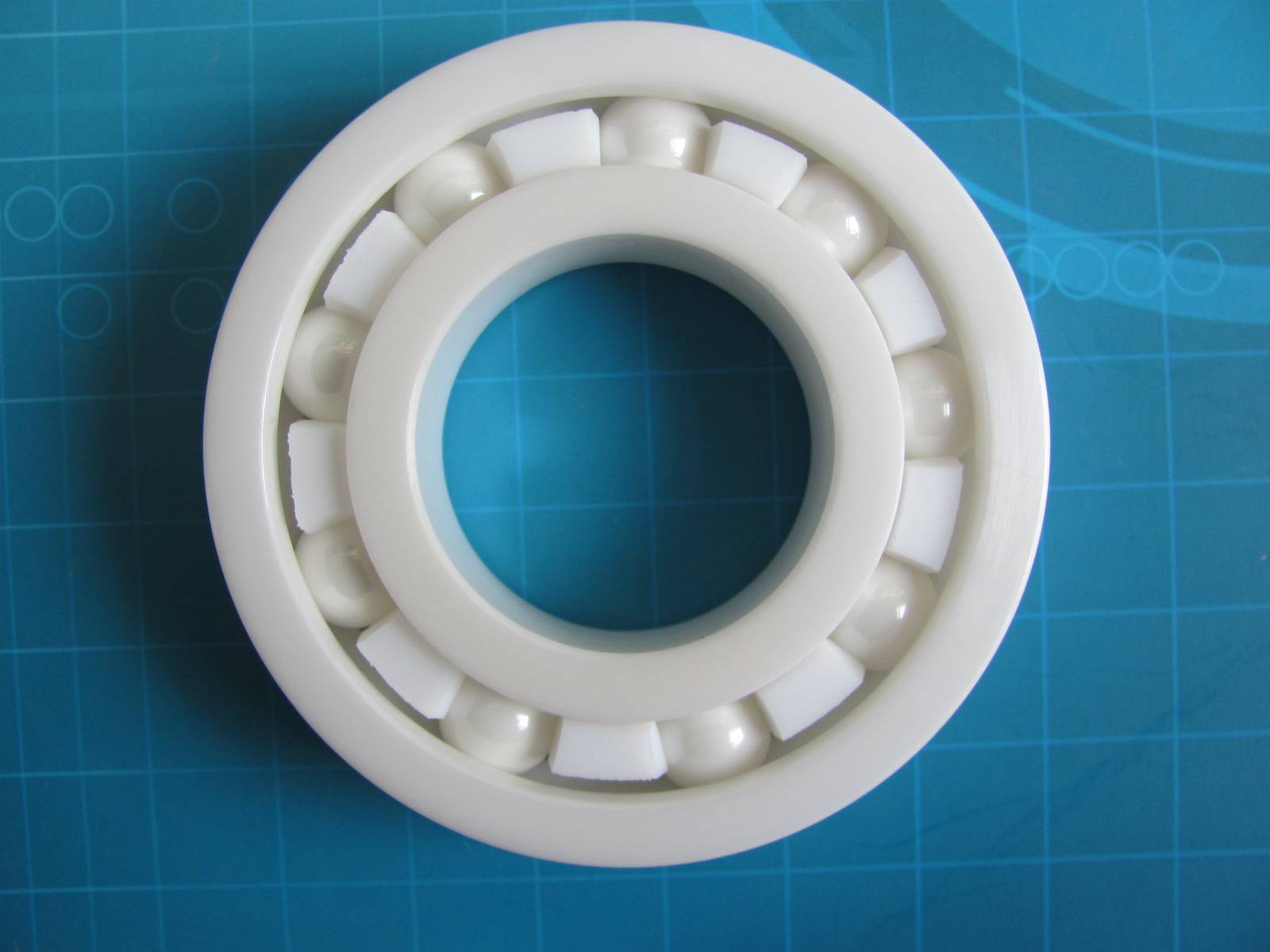

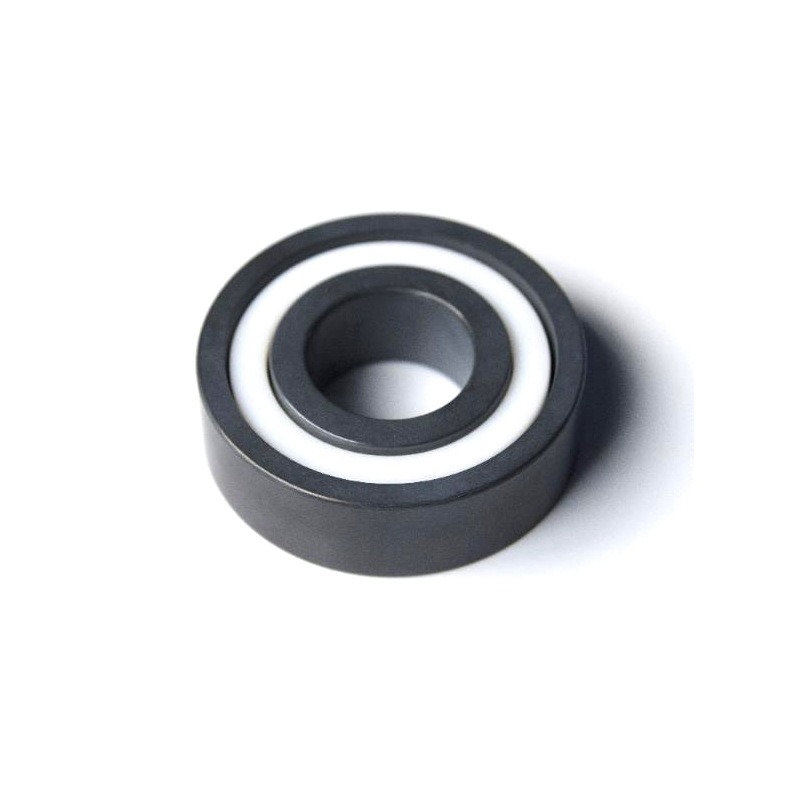

Insulated bearings are coated with a high-performance insulating material, typically alumina or glass fiber, on the inner or outer ring. These materials provide excellent electrical insulation while maintaining the mechanical strength and durability of the bearing. In some applications, ceramic balls are also used to further enhance the bearing’s insulating properties. Ceramic materials not only have high hardness and wear resistance but also offer superior electrical insulation.

The insulating layer of an insulated bearing can withstand thousands of volts of electricity, effectively isolating shaft currents in motor systems and preventing current from passing through the bearing. Even under high voltage and high-frequency conditions, the insulating layer maintains its electrical isolation properties, protecting the rolling elements and raceways from electrical corrosion.

2.Key Advantages of Insulated Bearings

I.Prevention of Electrical Corrosion: The most notable advantage of insulated bearings is their ability to effectively prevent electrical corrosion caused by current passing through the bearing. By stopping the flow of current through the bearing components, the surface damage to the bearing is significantly reduced, extending its service life.

II.Extended Equipment Life: Electrical corrosion not only damages bearings but can also affect the performance and reliability of the entire equipment. Using insulated bearings reduces equipment failures caused by electrical corrosion, thereby extending the service life of motors and other rotating equipment.

III.Improved Equipment Reliability: In many industrial applications, equipment stability and reliability are crucial. Insulated bearings can increase the uptime of motors and generators, reducing downtime and maintenance due to bearing failures.

IV.Multiple Insulation Material Options: Insulated bearings offer a variety of insulating materials, including ceramic coatings, resin coatings, or ceramic balls, to meet different application requirements. These options provide optimal insulation protection and mechanical performance.

3.Typical Application Areas of Insulated Bearings

Insulated bearings play an important role in multiple industries and applications, particularly in environments where high-frequency and high-voltage operation is required. The main application areas include:

I.Motors and Generators: Especially in motor systems driven by frequency converters, insulated bearings prevent current from passing through the bearing and protect the motor’s normal operation.

II.Wind Power Generation: In wind turbines, bearings operate under high-frequency and high-load conditions for extended periods and are also prone to electrical interference. Insulated bearings can effectively extend the life of wind turbine bearings and improve the operational efficiency of the equipment.

III.Rail Transit: The drive motors of electric trains need to ensure the stability and safety of the bearings during high-speed operation. Insulated bearings ensure reliable operation of the equipment under electrical interference.

When selecting insulated bearings, it is important to choose the appropriate insulating materials and design based on the specific application scenario and requirements. This ensures maximum protection against electrical corrosion and ensures stable equipment operation. If your equipment frequently suffers from bearing failures due to electrical interference, insulated bearings are the ideal choice to enhance equipment reliability and service life.

For more information, feel free to contact QIBR