Newsroom

What is Swing Ring of Forklift?

Forklifts are essential tools in various industrial settings, designed to enhance efficiency in loading, unloading, and transporting materials. A critical component of many forklift designs is the swing ring, also known as a slewing bearing. This article delves into the function, structure, and importance of swing rings in forklifts, as well as their safety implications.

What is a Swing Ring?

A swing ring or slewing bearing is a type of rotational rolling-element bearing that supports heavy loads while allowing for slow turning or oscillation. These bearings are designed to handle axial, radial, and moment loads, making them ideal for applications where stability and precision are crucial. In forklifts, swing rings facilitate the movement of attachments and the rotation of the load being handled.

Structure of Swing Rings

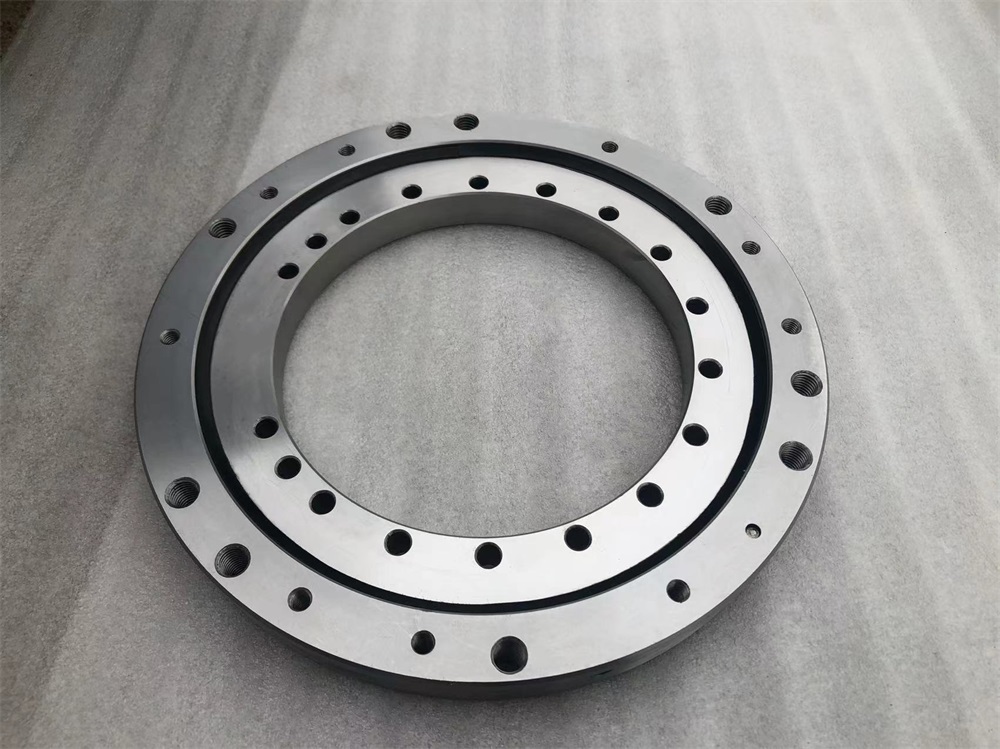

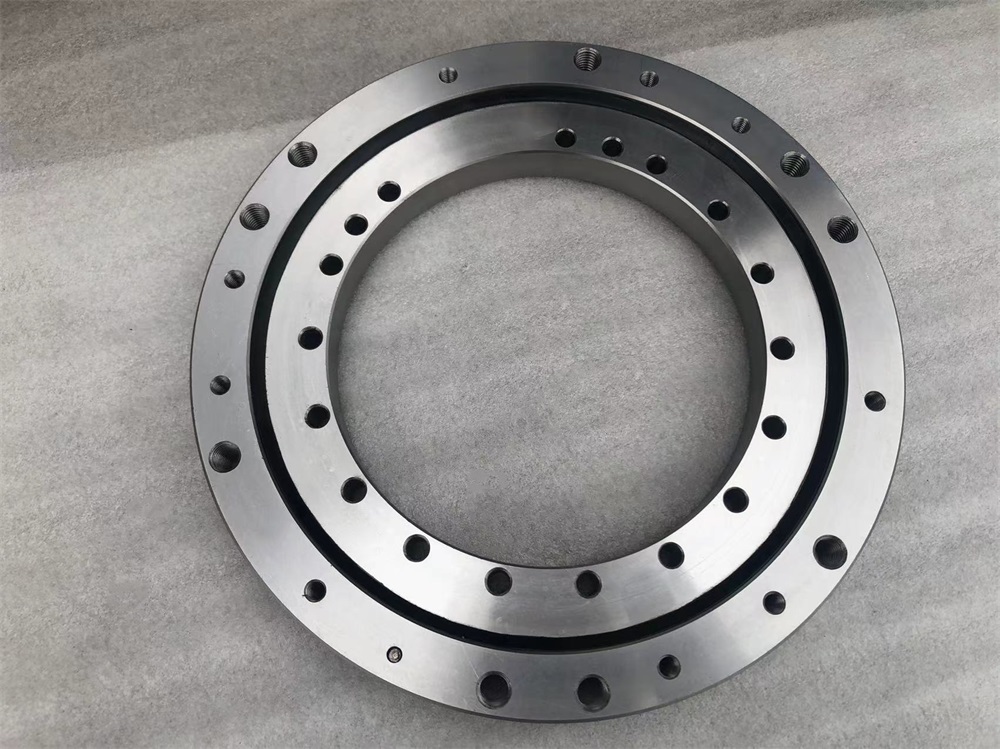

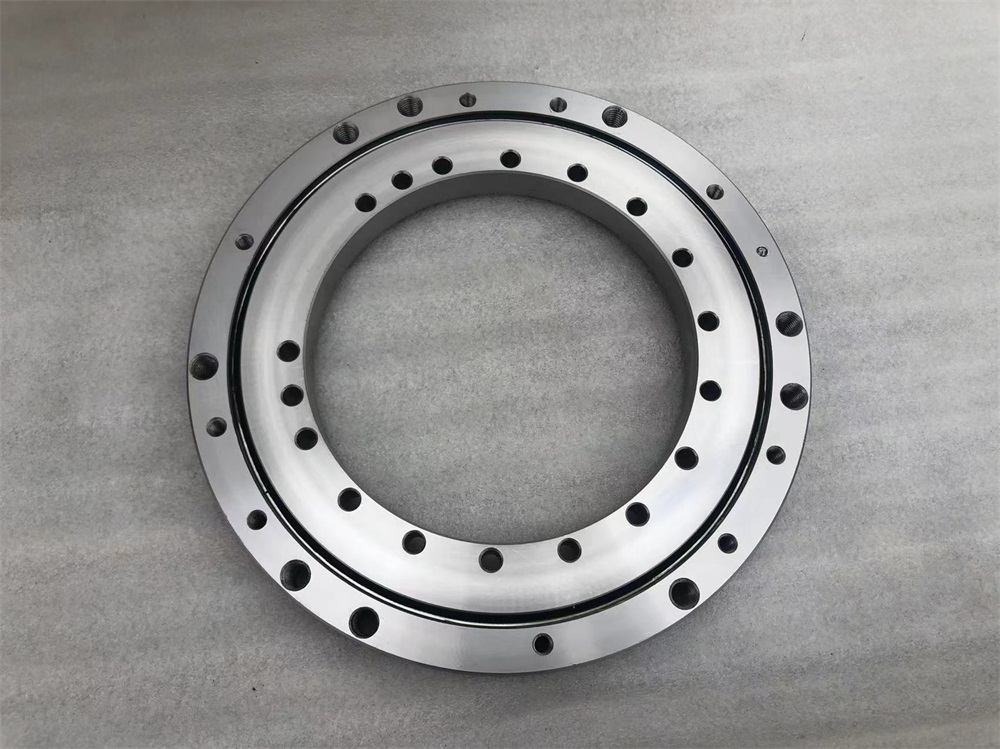

Swing rings typically consist of two main components: an inner ring and an outer ring. Both rings are often made from high-strength alloy steel to ensure durability and wear resistance. The design can vary, with options including single row ball or roller styles, double row configurations, and even combined designs that incorporate both balls and rollers.

Inner Ring: This part is attached to the forklift's structure and often features gear teeth that allow for powered rotation.

Outer Ring: This component is connected to the rotating platform or attachment, facilitating smooth movement.

The rings are usually wide with holes drilled in them for fixation to the forklift's frame. Seals may be included to protect the internal rolling elements from contaminants.

Importance of Swing Rings in Forklifts

Swing rings play a vital role in enhancing the operational capabilities of forklifts:

Load Stability: They provide a stable base for lifting and rotating heavy loads, which is essential for safe operation.

Precision Movement: The ability to rotate slowly allows operators to maneuver loads with great accuracy, reducing the risk of accidents.

Versatility: Swing rings enable various attachments to be used with forklifts, such as grapples or welding jigs, expanding their functionality beyond simple lifting tasks.

Safety Considerations

While swing rings significantly enhance forklift capabilities, they also introduce specific safety

Conclusion

Swing rings are integral components that enhance the functionality and safety of forklifts in various industrial applications. Their ability to support heavy loads while allowing for precise movement makes them invaluable in material handling tasks. However, with their benefits come responsibilities; proper training and safety protocols must be adhered to in order to mitigate risks associated with swinging loads. As industries continue to evolve, understanding the mechanics and safety implications of swing rings will remain essential for effective forklift operation.