Newsroom

What kind of bearings commonly used in fans?

2024-10-11The bearings commonly used in fans mainly include the following types

Fans mainly rely on the rotation of the impeller to generate air flow. The motor drives the impeller to rotate at high speed, so that the air obtains energy under the action of the impeller, thereby generating a pressure difference and pushing the air to flow. Centrifugal fans suck in air along the axial direction through the impeller and then throw it out radially under the action of centrifugal force; axial flow fans let the air flow along the axial direction of the impeller and directly push the air forward. As an important mechanical equipment, fans are widely used in various fields. The following are the types of bearings commonly used in fans.

Deep groove ball bearing:

Features: Mainly bear radial load, and can also bear small axial load at the same time. It has the advantages of small friction coefficient, high limit speed, simple structure and low manufacturing cost.

Application scenarios: Widely used in small fans and fans with low requirements for axial load. For example, some household ventilation fans, small industrial exhaust fans, etc.

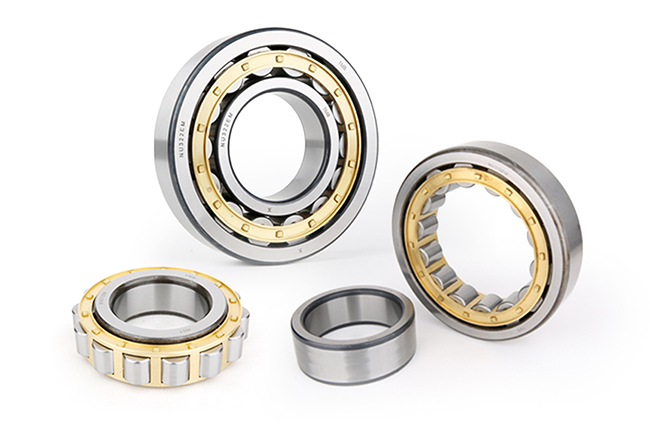

Cylindrical roller bearing:

Features: Bear larger radial load, and the bearing capacity is higher than that of deep groove ball bearings. However, the ability to bear axial load is small, and it needs to be used in conjunction with other bearings that can bear axial load.

Application scenarios: It is more common in the main shaft support of medium and large fans, especially in those occasions where the radial bearing capacity is required to be high.

Spherical roller bearing:

Features: It has an automatic self-aligning function and can compensate for the axis offset caused by installation errors or shaft deformation. It can bear a large radial load and a certain degree of axial load.

Application scenarios: Used when the installation accuracy of the fan is not high or the shaft is prone to deformation during operation, such as when some large industrial fans are installed on an uneven foundation.

Good maintenance of fan bearings is crucial to ensuring the normal operation of fans and prolonging their service life. The maintenance of fan bearings needs to start from aspects such as daily inspection, lubrication management, precautions for installation and disassembly, and regular maintenance to ensure the normal operation and service life of the bearings. At the same time, a reasonable maintenance plan should be formulated according to the actual situation of the fan and maintained strictly in accordance with the plan.

By following these steps, you can effectively find and use interchangeable bearings for your applications. If you have a specific bearing in mind that you need to interchange, let me know, and I can help further!