Newsroom

What should be noted when installing a thrust ball bearing?

2025-05-23When installing a thrust ball bearing, the verticality of the shaft ring and the shaft centerline should be checked. The method is to fix the micrometer on the end face of the housing, so that the contact of the meter is on the bearing shaft ring raceway while rotating the bearing and observing the micrometer pointer. If the pointer is deflected, it means that the shaft ring and the shaft centerline are not vertical. When the housing hole is deep, it can also be checked with an extended micrometer head.

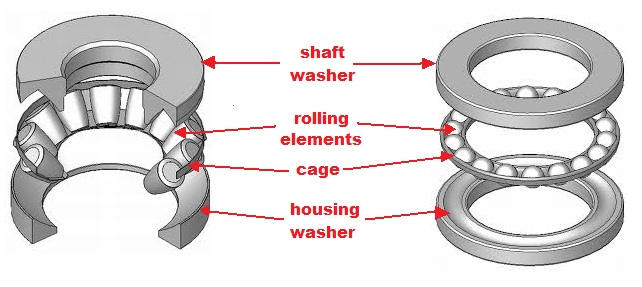

When the thrust ball bearing is installed correctly, its seat ring can automatically adapt to the rolling of the rolling body to ensure that the rolling body is located in the upper and lower ring raceways. If it is installed upside down, not only will the bearing work abnormally, but the mating surfaces will be severely worn. Since the difference between the shaft ring and the seat ring is not very obvious, you should be extra careful during assembly and do not make mistakes.

In addition, a gap of 0.2–0.5 mm should be left between the seat ring of the thrust ball bearing and the bearing seat hole to compensate for the errors caused by inaccurate processing and installation of parts. When the center of the bearing ring is offset during operation, this gap can ensure its automatic adjustment to avoid contact friction and enable it to operate normally. Otherwise, it will cause severe damage to the bearing.

For more information, feel free to contact QIBR