Newsroom

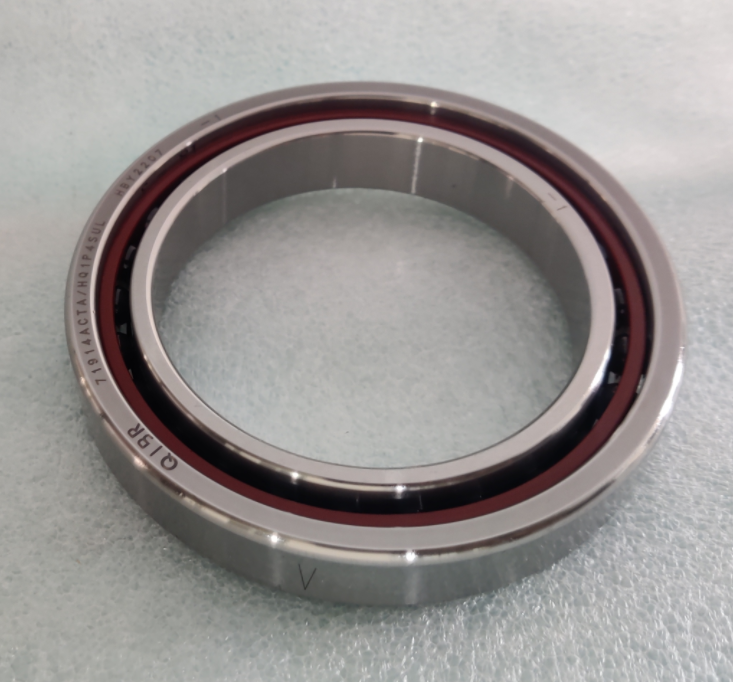

What to do when a machine tool spindle bearing overheats

2025-05-30The spindle bearing is one of the most important components in a machine tool. Once the spindle bearing temperature becomes too high, it can be considered a serious fault for rotating equipment. If not handled properly, it will shorten the bearing’s service life and may even cause bearing burnout, affecting the normal operation of the machine tool. So, what causes spindle bearing overheating, and how can it be resolved?

1.Poor Bearing Quality:

The quality of the spindle bearing is crucial to both the operation of the machine tool and the service life of the spindle. The precision, lifespan, and reliability of the machine tool spindle largely depend on the bearing. Therefore, during the procurement and inspection process, it is essential to check carefully and select qualified, high-quality products from reputable manufacturers.

2.Improper Bearing Selection:

When selecting a spindle bearing, attention must be paid to its limiting speed and load capacity. Bearings must not be used beyond their rated speed or load; otherwise, this will only shorten their service life and result in more harm than good.

3.Poor Lubrication:

Lubrication plays a critical role in the service life of spindle bearings, as well as in reducing friction, wear, and vibration. Good lubrication is essential for the proper functioning of spindle bearings. According to statistics, about 40% of spindle bearing failures are related to poor lubrication.

4.Improper Installation:

Incorrect installation is also a major cause of spindle bearing overheating. Whether the bearing is installed properly directly affects its service life and the precision of the machine.

5.Failure to Inspect and Replace in Time:

If the spindle bearing shows signs of severe fatigue spalling, oxidation, rust, wear marks, or cracks, or if there is excessive noise that cannot be corrected, failure to replace it in time may lead to overheating, abnormal noise, and vibration, ultimately affecting normal production.

6.Heat Caused by Wear:

Spindle bearingsmay overheat due to rust and wear. Prolonged fatigue usage or operation in humid environments can cause various parts of the spindle to become worn or corroded. Even long-term storage without use may lead to bearing rust.

7.Inadequate Cooling:

Common signs of inadequate cooling include blocked pipelines, improperly selected coolers, or poor cooling performance.

For more information, feel free to contact QIBR