Newsroom

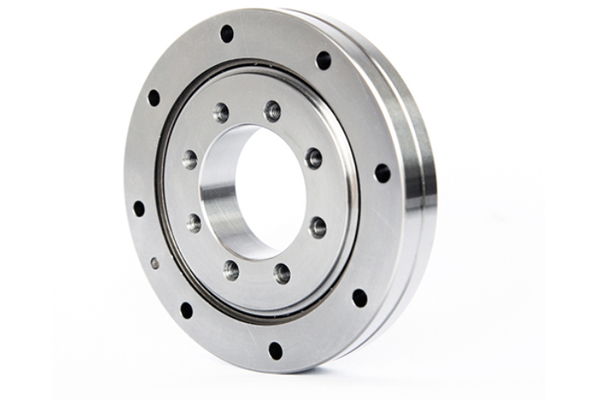

Why Are Crossed Roller Bearings Ideal for Robotic Arms?

2025-06-13In industrial robots, robotic arms typically perform both linear and rotary motions. Linear movements such as extension and horizontal displacement are usually achieved through mechanisms like pneumatic (or hydraulic) cylinders, ball screw drives, rack and pinion systems, or linkages. Rotary movements, such as rotation and tilting, involve various transmission mechanisms. In both cases, crossed roller bearings are widely used due to their structural advantages—especially in joints or rotating platforms.

1.Supporting Linear Motion:

To achieve linear motion, robotic arms often rely on compact and lightweight transmission systems. Crossed roller bearings are particularly suitable for these scenarios because of their compact size, low profile, and high rigidity, which are essential in space-constrained robotic designs.

2.Ideal for Rotary Motion:

For rotary movements in robotic arms—realized through vane-type actuators, gear mechanisms, chain drives, or piston-cylinder linkages—crossed roller bearings offer several key advantages:

- Ultra-compact structure for space-saving design;

- Simultaneous multi-directional load capacity;

- High rigidity and precision;

- Adjustable clearance structure for minimized error.

3.Suitable for Complex Dynamic Loads:

Robot arms typically have 2 to 3 degrees of freedom and are subject to both static and dynamic loads, especially during high-speed operations. These create large inertial forces or moments, which can affect positioning accuracy. Crossed roller bearings’ ability to absorb impact, handle complex loads, and maintain stability under dynamic conditions makes them an ideal choice for these applications.

4.Conclusion:

Thanks to their compact size, high rigidity, multi-directional load capability, and precision rotation, crossed roller bearings are particularly well-suited for critical sections of industrial robotic arms. Whether enabling precise joint movement or maintaining high accuracy under heavy loads, they outperform traditional bearing types and have become essential components in modern robotics.

For more information, feel free to contact QIBR