Newsroom

Why Are Slewing Bearings Necessary?

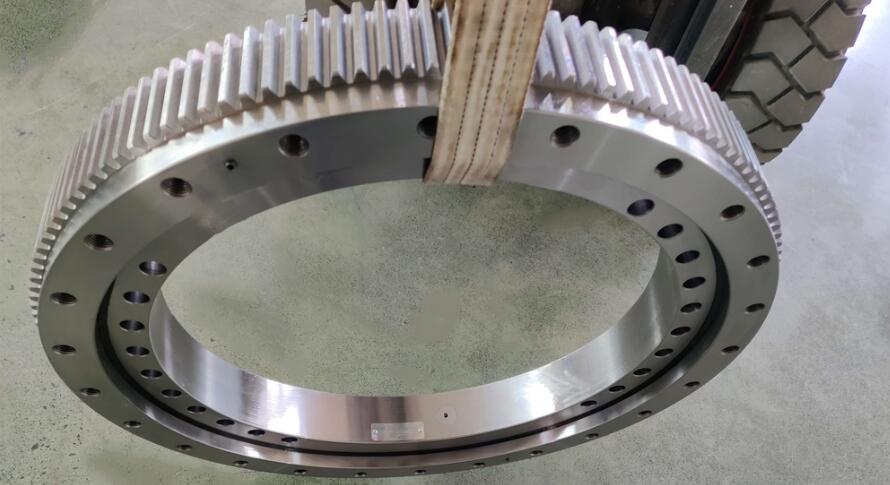

2024-08-04Slewing bearings play a crucial role in many industrial and mechanical applications. Their primary function is to support heavy loads during rotational movements and ensure smooth operation. They significantly optimize equipment performance, extend service life, and enhance work efficiency. Slewing bearings offer various advantages, making them an indispensable part of many types of machinery.

1. Availability

The design of slewing bearings particularly emphasizes ease of installation. The inner and outer rings are equipped with mounting holes, making the installation process simpler and more efficient. Whether it’s an initial installation or later maintenance, these holes help technicians quickly locate and secure the bearings. Once installed, slewing bearings can stably support heavy loads while providing flexible rotational capabilities. This design greatly simplifies the installation process, reduces downtime, and improves the overall operational efficiency of the equipment.

2. Performance

Slewing bearings are highly favored for their robust and compact structure. They occupy minimal space, making them suitable for applications requiring space-saving or weight restrictions. For instance, in some high-precision industrial equipment, space is often very limited, but the requirements for bearing strength and stability are very high. In such cases, slewing bearings offer an ideal solution. Their compact design does not affect the overall structure of the equipment and can still provide excellent performance. These bearings can withstand high loads and ensure smooth operation, allowing the equipment to maintain good performance under high-intensity working conditions.

3. Load Capacity

The design and structure of slewing bearings endow them with excellent load capacity. They can handle extreme torque loads, making them suitable for various complex and demanding working environments. Whether it’s heavy vertical loads or horizontal impact forces, these bearings can provide stable support and rotational capabilities. Particularly in large machinery such as cranes, excavators, and wind turbines, the strong load capacity of slewing bearings is crucial. They not only bear the weight of the equipment itself but also cope with the impact and vibration of external loads, ensuring the safe and stable operation of the equipment under various complex conditions.

In summary, slewing bearings, with their outstanding availability, performance, and load capacity, play an irreplaceable role in various industrial and mechanical applications. They simplify the installation and maintenance process, provide excellent rotational performance, and offer strong load capacity. Whether in saving space, reducing weight, or handling extreme loads, slewing bearings demonstrate their unique advantages. With continuous technological advancements and increasing application demands, slewing bearings will continue to play a significant role in various fields, supporting the efficient operation and long-term use of industrial equipment. Contact us to know more.