Newsroom

wire race bearing structure and feature

2025-12-03  Wire race bearings, also known as wire runway bearings, get their name from the use of wire as the raceway. Below is an introduction to their features and structure:

Wire race bearings, also known as wire runway bearings, get their name from the use of wire as the raceway. Below is an introduction to their features and structure:

Structure

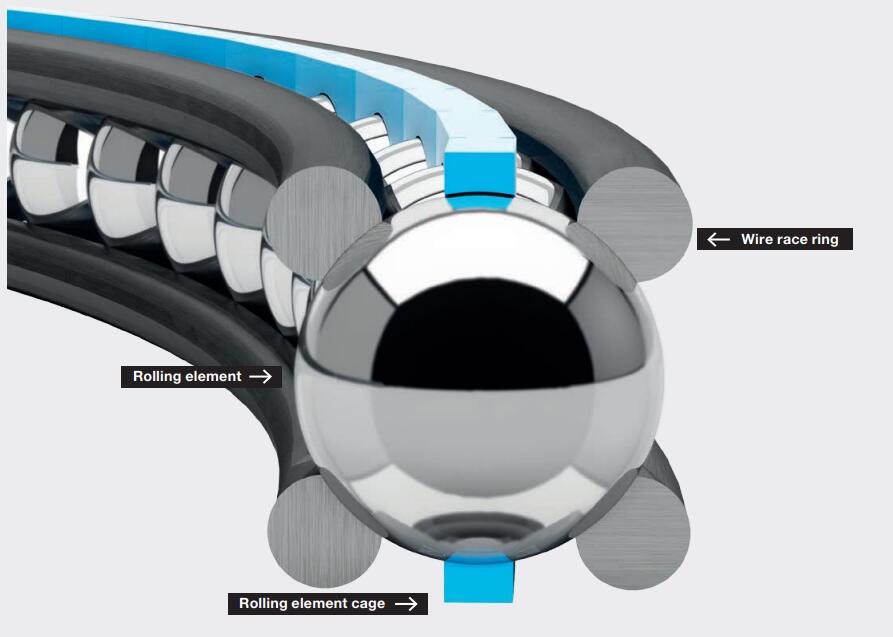

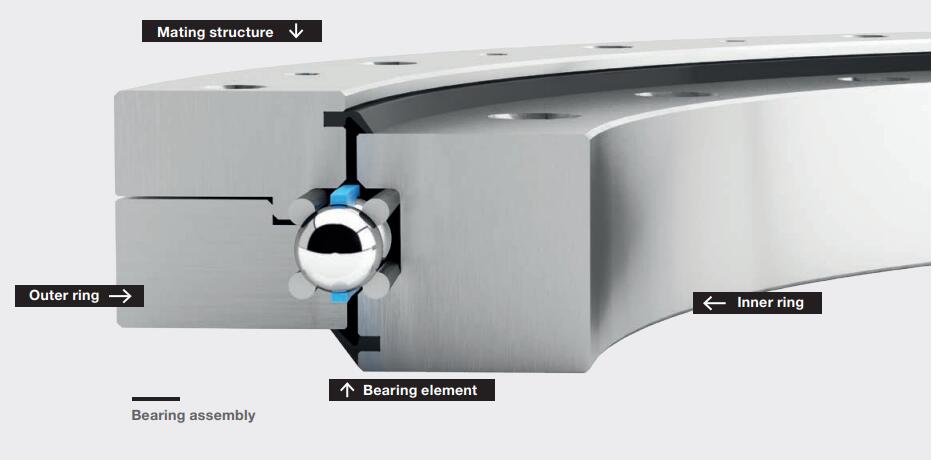

- Basic Components: They mainly consist of rolling elements (balls or rollers), a cage, wire raceway rings, and inner and outer support rings. Specifically, circular ball wire raceway rings and flat roller wire raceway rings are respectively installed in the grooves of the outer and inner support rings. Balls and cylindrical rollers are placed in the cylindrical holes and rectangular holes of the same cage. The balls can roll on the ground surface of the circular wire raceway ring, and the rollers can roll on the ground surface of the flat wire raceway ring.

- Typical Structural Forms: There is a three-entity enclosed structure, generally composed of a fixed large tabletop body, a movable needle cylinder base gear, and a pressure ring, which enclose the wire race bearings in the middle. According to the installation position of the pressure ring relative to the ball and the center of the needle cylinder, it can be divided into four forms: upper inner-side pressure ring type, upper outer-side pressure ring type, lower inner-side pressure ring type, and lower outer-side pressure ring type.

Features

Small Cross-Sectional Area: They occupy a very small cross-sectional area, which allows for very delicate design in the machine, and are suitable for large-diameter rotation and machines requiring low energy consumption.

High Load-Bearing Capacity: They have the characteristics of both ball and roller bearings, and can simultaneously bear centrifugal force and axial force. Some wire race bearings with a four-point contact structure can also bear radial loads, axial loads, and overturning moments.

High Precision: The high precision of wire race bearings comes from the special raceway grinding process. The small clearance between the rolling elements and the wire raceway also contributes to their high-precision operation.

Lightweight and Simple Structure: Compared with ordinary slewing bearings, they have the advantages of light weight, simple structure, small installation space, convenient maintenance and replacement, and low cost.

Good Sealing Performance: The rolling process occurs in the raceway ring, and the steel balls are separated by a nylon isolation belt, which has a certain sealing effect and can reduce the entry of dust and other impurities.