Newsroom

YRT combined precision bearing characters

2022-10-11YRT combined precision bearing is a kind of composite structure thrust/radial bearing specially designed for high-precision rotary motion, and is widely used in the core rotary components of high-end equipment. The following analysis focuses on the structure, load - carrying capacity, precision and application scenarios of the turntable bearing around the characteristics of "high precision, high rigidity and composite load support".

I. Structural Features: Integrated Composite Design for Multi-direction Support

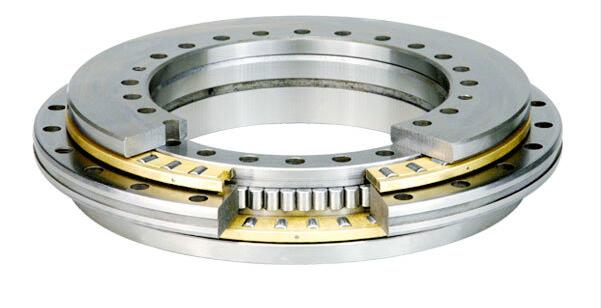

YRT combined precision bearing realizes the integrated support of "radial + axial + overturning moment" through the integration of multiple components. The specific features are as follows:

Core Structural Composition

A typical YRT combined precision bearing consists of the following key components:

- Thrust/radial seat ring (outer ring): It is fixed on the equipment base or frame as the static support part of the bearing. The inner ring raceway contacts both radial and axial rolling elements at the same time.

- Thrust/radial shaft ring (inner ring): It is connected with the rotary worktable or rotating parts, rotates with the moving parts, and the outer ring raceway contacts the rolling elements correspondingly.

- Radial cylindrical roller assembly: Distributed on the inner side of the bearing, it contacts with the radial raceways of the inner and outer rings, specially bears radial force, and ensures the radial positioning accuracy during rotation.

- Bidirectional thrust needle roller cage assembly: Symmetrically distributed on both sides of the shaft ring (up and down or left and right), the needle rollers contact with the end face thrust raceways of the shaft ring and the seat ring, bear bidirectional axial force, and resist axial 窜动.

- Isolation block and preloading structure: Some models eliminate clearance and improve rigidity through built-in isolation blocks or bolt preloading design.

- Optional integrated components: Some high-end models (such as YRTM series) integrate angle measurement systems such as steel grating rulers or encoders to directly realize real-time feedback of rotation angles.

Structural Advantages

- Gap-free design: Through precision machining and preloading control, the rolling elements are in close contact with the raceway, with almost no clearance, ensuring motion stability.

- Compact integration: The radial and axial load-carrying functions are integrated into a single bearing, simplifying the equipment structure and reducing installation errors.

- Symmetrical layout: The thrust needle roller assemblies are symmetrically distributed, with uniform force, which can effectively resist overturning moment.

II. Load-Carrying Capacity: Multi-direction Composite Loading with High Rigidity and Deformation Resistance

The load-carrying capacity of YRT combined precision bearing is its core performance, which can cope with complex loads at the same time. The specific features are as follows:

Load Types

- Radial load carrying: Radial force is transmitted through radial cylindrical rollers. The rollers are in line contact with the raceway, with a large contact area, high radial rigidity, and can bear large radial loads (usually up to several thousand Newtons to tens of thousands of Newtons, depending on the bearing size).

- Bidirectional axial load carrying: The thrust needle roller assemblies on both sides symmetrically bear bidirectional axial force. The needle rollers are slender in structure, and their line contact characteristics make them have strong axial load-carrying capacity and better impact resistance than ball bearings.

- Overturning moment carrying: Due to the symmetrical structure and high rigidity of the raceway, the bearing can bear large overturning moment (generated by the eccentricity of radial force or axial force), effectively inhibiting the inclination or deformation of the rotating parts and ensuring the rotation stability (the overturning moment carrying capacity is usually proportional to the cube of the bearing diameter).

Load-Carrying Advantages

- Compatibility with composite loads: It can independently support the composite load of "radial force + bidirectional axial force + overturning moment" without the assistance of additional bearings, solving the limitation that ordinary bearings need to be used in combination.

- High rigidity design: The interference fit between the rolling elements and the raceway (in the preloaded state) makes the overall rigidity of the bearing extremely high, and the deformation under high load is minimal (micron level), ensuring that the equipment can maintain precision under heavy load.

III. Precision: Micron-level Control to Meet the Needs of High-end Equipment

The precision of YRT combined precision bearing is its core competitiveness, which realizes ultra-precision motion control through strict processing and assembly processes. The specific indicators are as follows:

Precision Grade

The conventional precision grade is P4 grade, and high-end models can reach P2 grade (according to ISO 1132 - 1 standard), which is much higher than that of ordinary bearings (ordinary bearings are mostly P0-P6 grades).

Key Precision Indicators

- Radial runout: The radial offset of the inner ring relative to the outer ring. For P4 grade bearings, the radial runout is ≤ 5μm, and for P2 grade, it can be controlled within 2μm.

- Axial runout: The axial offset of the shaft ring end face relative to the seat ring. For P4 grade, it is ≤ 5μm, and for P2 grade, it is ≤ 3μm.

- Repeat positioning accuracy: The error of the rotating part when rotating to the same angle for many times is usually ≤ 3 arcseconds (0.0008°), and high-end models can reach within 1 arcsecond.

- Rotation accuracy: The angular velocity fluctuation during rotation is small, and the vibration and noise are extremely low (the operating noise is usually < 60dB).

Precision Assurance Processes

- The raceway surface is processed by ultra-precision grinding, with a roughness of ≤ Ra0.1μm, ensuring uniform contact of rolling elements.

- The rolling elements (cylindrical rollers, needle rollers) have extremely high dimensional consistency (tolerance ≤ 1μm), avoiding uneven load distribution caused by dimensional differences.

- During the assembly process, precision equipment such as laser interferometers are used to measure the runout in real time to ensure that the precision meets the standard.

IV. Application Scenarios: Focusing on Core Rotary Components of High-end Equipment

The application scenarios of YRT combined precision bearings all need to meet the requirements of "high precision, high load and high stability", mainly focusing on the following fields:

CNC Machine Tools and Machining Centers

- As the rotary worktable bearing of vertical/horizontal machining centers, it supports the worktable to achieve precise indexing (such as C-axis rotation in five - axis linkage machining), ensuring the position accuracy of multi-face machining of parts (such as complex curved surface machining of aerospace parts).

- Applied to CNC indexing heads and CNC turntables, it realizes high - precision rotation positioning of workpieces, and the repeat positioning error needs to be controlled within 5μm.

Precision Measurement and Testing Equipment

- In the rotating shaft of coordinate measuring machines, roundness meters and gear measuring instruments, it serves as the core rotary support, ensuring the angle positioning accuracy and radial/axial stability during measurement, which directly affects the accuracy of measurement data.

- The rotary components of laser trackers and laser interferometers require bearings to be gap-free and low-vibration to ensure the stability of the laser optical path.

Aerospace and Military Equipment

- The rotary support of radar antenna pedestals needs to bear radial force, axial force and overturning moment generated by the antenna's own weight and wind force, while ensuring the antenna pointing accuracy (arcsecond level).

- The rotating mechanisms of missile launchers, shipborne radars and tank turrets need to maintain high-precision rotation in harsh environments (vibration, impact, high and low temperatures), with extremely high reliability requirements.

High-end Automation Equipment

- The worktable rotating shaft of semiconductor wafer lithography machines requires nanometer-level positioning accuracy, and the high rigidity and low runout of YRT bearings are the core guarantee.

- The waist rotary joints and precision rotating platforms of industrial robots need to bear the composite load of the robot's own weight and load at the same time to ensure smooth movement.