Image may differ from product. See technical specification for details.

Search for the bearing model you need

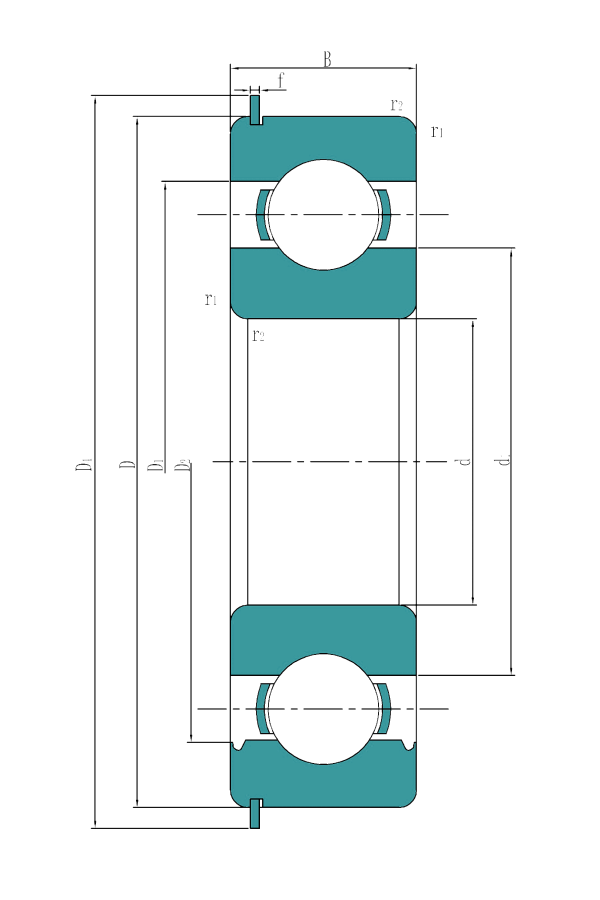

Shaft abutment diameter (da)

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

GCr15、5200、100Cr6、SUJ2

Inner ring diameter

10mm-120mm

Outer ring diameter

30mm-180mm

Weight

0.032kg-3.05kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Inner diameter (d) | Mass | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 101 |

|

6311 ZNR | 74.1 KN | 45 KN | 55 mm | 1.45 kg | 120 mm | 29 mm |

| 102 |

|

6311 2ZNR | 74.1 KN | 45 KN | 55 mm | 1.45 kg | 120 mm | 29 mm |

| 103 |

|

6311 N | 74.1 KN | 45 KN | 55 mm | 1.4 kg | 120 mm | 29 mm |

| 104 |

|

6311 NR | 74.1 KN | 45 KN | 55 mm | 1.4 kg | 120 mm | 29 mm |

| 105 |

|

6012 N | 30.7 KN | 23.2 KN | 60 mm | 0.43 kg | 95 mm | 18 mm |

| 106 |

|

6012 NR | 30.7 KN | 23.2 KN | 60 mm | 0.43 kg | 95 mm | 18 mm |

| 107 |

|

6212 ZNR | 55.3 KN | 36 KN | 60 mm | 0.83 kg | 110 mm | 22 mm |

| 108 |

|

6212 2ZNR | 55.3 KN | 36 KN | 60 mm | 0.83 kg | 110 mm | 22 mm |

| 109 |

|

6212 N | 55.3 KN | 36 KN | 60 mm | 0.8 kg | 110 mm | 22 mm |

| 110 |

|

6212 NR | 55.3 KN | 36 KN | 60 mm | 0.8 kg | 110 mm | 22 mm |

| 111 |

|

6312 ZNR | 85.2 KN | 52 KN | 60 mm | 1.8 kg | 130 mm | 31 mm |

| 112 |

|

6312 2ZNR | 85.2 KN | 52 KN | 60 mm | 1.8 kg | 130 mm | 31 mm |

| 113 |

|

6312 N | 85.2 KN | 52 KN | 60 mm | 1.75 kg | 130 mm | 31 mm |

| 114 |

|

6312 NR | 85.2 KN | 52 KN | 60 mm | 1.75 kg | 130 mm | 31 mm |

| 115 |

|

6013 N | 31.9 KN | 25 KN | 65 mm | 0.45 kg | 100 mm | 18 mm |

| 116 |

|

6013 NR | 31.9 KN | 25 KN | 65 mm | 0.45 kg | 100 mm | 18 mm |

| 117 |

|

6213 ZNR | 58.5 KN | 40.5 KN | 65 mm | 1.1 kg | 120 mm | 23 mm |

| 118 |

|

6213 2ZNR | 58.5 KN | 40.5 KN | 65 mm | 1.1 kg | 120 mm | 23 mm |

| 119 |

|

6213 N | 58.5 KN | 40.5 KN | 65 mm | 1.05 kg | 120 mm | 23 mm |

| 120 |

|

6213 NR | 58.5 KN | 40.5 KN | 65 mm | 1.05 kg | 120 mm | 23 mm |

| 121 |

|

6313 ZNR | 97.5 KN | 60 KN | 65 mm | 2.25 kg | 140 mm | 33 mm |

| 122 |

|

6313 2ZNR | 97.5 KN | 60 KN | 65 mm | 2.25 kg | 140 mm | 33 mm |

| 123 |

|

6313 N | 97.5 KN | 60 KN | 65 mm | 2.15 kg | 140 mm | 33 mm |

| 124 |

|

6313 NR | 97.5 KN | 60 KN | 65 mm | 2.15 kg | 140 mm | 33 mm |

| 125 |

|

6014 N | 39.7 KN | 31 KN | 70 mm | 0.63 kg | 110 mm | 20 mm |

| 126 |

|

6014 NR | 39.7 KN | 31 KN | 70 mm | 0.63 kg | 110 mm | 20 mm |

| 127 |

|

6214 ZNR | 63.7 KN | 45 KN | 70 mm | 1.15 kg | 125 mm | 24 mm |

| 128 |

|

6214 2ZNR | 63.7 KN | 45 KN | 70 mm | 1.15 kg | 125 mm | 24 mm |

| 129 |

|

6214 N | 63.7 KN | 45 KN | 70 mm | 1.15 kg | 125 mm | 24 mm |

| 130 |

|

6214 NR | 63.7 KN | 45 KN | 70 mm | 1.15 kg | 125 mm | 24 mm |

| 131 |

|

6314 ZNR | 111 KN | 68 KN | 70 mm | 2.65 kg | 150 mm | 35 mm |

| 132 |

|

6314 2ZNR | 111 KN | 68 KN | 70 mm | 2.65 kg | 150 mm | 35 mm |

| 133 |

|

6314 N | 111 KN | 68 KN | 70 mm | 2.6 kg | 150 mm | 35 mm |

| 134 |

|

6314 NR | 111 KN | 68 KN | 70 mm | 2.6 kg | 150 mm | 35 mm |

| 135 |

|

6015 N | 41.6 KN | 33.5 KN | 75 mm | 0.67 kg | 115 mm | 20 mm |

| 136 |

|

6015 NR | 41.6 KN | 33.5 KN | 75 mm | 0.67 kg | 115 mm | 20 mm |

| 137 |

|

6215 N | 68.9 KN | 49 KN | 75 mm | 1.25 kg | 130 mm | 25 mm |

| 138 |

|

6215 NR | 68.9 KN | 49 KN | 75 mm | 1.25 kg | 130 mm | 25 mm |

| 139 |

|

6315 N | 119 KN | 76.5 KN | 75 mm | 3.05 kg | 160 mm | 37 mm |

| 140 |

|

6315 NR | 119 KN | 76.5 KN | 75 mm | 3.05 kg | 160 mm | 37 mm |

| 141 |

|

6016 N | 49.4 KN | 40 KN | 80 mm | 0.92 kg | 125 mm | 22 mm |

| 142 |

|

6016 NR | 49.4 KN | 40 KN | 80 mm | 0.92 kg | 125 mm | 22mm |

| 143 |

|

6216 N | 72.8 KN | 55 KN | 80 mm | 1.5 kg | 140 mm | 26 mm |

| 144 |

|

6216 NR | 72.8 KN | 55 KN | 80 mm | 1.5 kg | 140 mm | 26 mm |

| 145 |

|

6017 N | 52 KN | 43 KN | 85 mm | 0.94 kg | 130 mm | 22 mm |

| 146 |

|

6017 NR | 52 KN | 43 KN | 85 mm | 0.94 kg | 130 mm | 22 mm |

| 147 |

|

6018 N | 60.5 KN | 50 KN | 90 mm | 1.2 kg | 140 mm | 24mm |

| 148 |

|

6018 NR | 60.5 KN | 50 KN | 90 mm | 1.2 kg | 140 mm | 24 mm |

| 149 |

|

6218 N | 101 KN | 73.5 KN | 90 mm | 2.25 kg | 160 mm | 30 mm |

| 150 |

|

6218 NR | 101 KN | 73.5 KN | 90 mm | 2.25 kg | 160 mm | 30 mm |

| 151 |

|

6219 N | 114 KN | 81.5 KN | 95 mm | 2.7 kg | 170 mm | 32 mm |

| 152 |

|

6219 NR | 114 KN | 81.5 KN | 95 mm | 2.7 kg | 170 mm | 32 mm |

| 153 |

|

6020 N | 63.7 KN | 54 KN | 100 mm | 1.3 kg | 150 mm | 24 mm |

| 154 |

|

6020 NR | 63.7 KN | 54 KN | 100 mm | 1.3 kg | 150 mm | 24 mm |

| 155 |

|

6021 N | 76.1 KN | 65.5 KN | 105 mm | 1.65 kg | 160 mm | 26 mm |

| 156 |

|

6021 NR | 76.1 KN | 65.5 KN | 105 mm | 1.65 kg | 160 mm | 26 mm |

| 157 |

|

6022 NR | 85.2 KN | 73.5 KN | 110 mm | 2.05 kg | 170 mm | 28 mm |

| 158 |

|

6022 N | 85.2 KN | 73.5 KN | 110 mm | 2.05 kg | 170 mm | 28 mm |

| 159 |

|

6024 N | 88.4 KN | 80 KN | 120 mm | 2.2 kg | 180 mm | 28 mm |

| 160 |

|

6024 NR | 88.4 KN | 80 KN | 120 mm | 2.2 kg | 180 mm | 28 mm |

Features and advantages of QIBR deep groove ball bearings with snap rings

QIBR deep groove ball bearings with snap rings address several critical issues in various fields, highlighted in the following aspects:

1. Snap ring functionality

The snap ring primarily prevents axial displacement of the bearing's inner or outer ring during operation. Typically, the inner ring is fixed, while the outer ring can move axially with the shaft or housing. The snap ring restricts this axial movement, ensuring greater stability during operation.

2. Enhanced axial load capacity

These bearings effectively control axial load capacity, reducing damage or performance degradation caused by axial displacement. The snap ring helps share part of the axial load, improving the overall bearing load capacity.

3. Simplified assembly and disassembly

The snap ring aids in positioning bearing components during assembly, minimizing errors and preventing accidental loosening of parts. Its design also simplifies bearing disassembly by making it easier to locate and remove the bearing without causing misalignment between the inner and outer rings.

4. Extended service life

By enhancing axial stability, the snap ring reduces wear and damage caused by excessive axial displacement, thereby extending the bearing’s service life.

Performance enhancements and solutions for QIBR deep groove ball bearings with snap rings

1.Preventing excessive axial displacement

The snap ring is a critical design element that limits axial displacement, ensuring stable operation under varying loads or external vibrations.

2. Raceway optimization

Enhancing the geometry, precision, and surface finish of the raceways reduces friction and energy loss, thereby improving operational efficiency.

3. Improved rolling element quality

Enhancing the surface finish and hardness of rolling elements reduces friction and wear. Using high-precision rolling elements (e.g., ceramic) can significantly boost bearing performance.

4. Corrosion resistance design

For demanding environments like marine or chemical applications, using stainless steel, corrosion-resistant coatings, or advanced surface treatments can enhance the bearing's resistance to corrosion.

Primary application fields for QIBR deep groove ball bearings with snap rings

Engines and transmission systems

In automotive engines, gearboxes, and wheel hubs, these bearings support rotating components, ensuring their stability and smooth operation. Snap rings prevent axial displacement caused by heavy loads or vibrations.

Optical instruments and precision machinery

In high-precision devices such as laser equipment, microscopes, and optical imaging systems, these bearings ensure precise operation without axial errors, maintaining high positioning accuracy and stability.

Aircraft engines and landing gear

In critical aircraft components like engines and landing gear, these bearings effectively prevent axial displacement, maintaining stable operation and ensuring flight safety.

Machine tools

In CNC machines or other precision mechanical equipment, these bearings ensure the stability of rotating components, particularly under varying loads or high-speed operations.