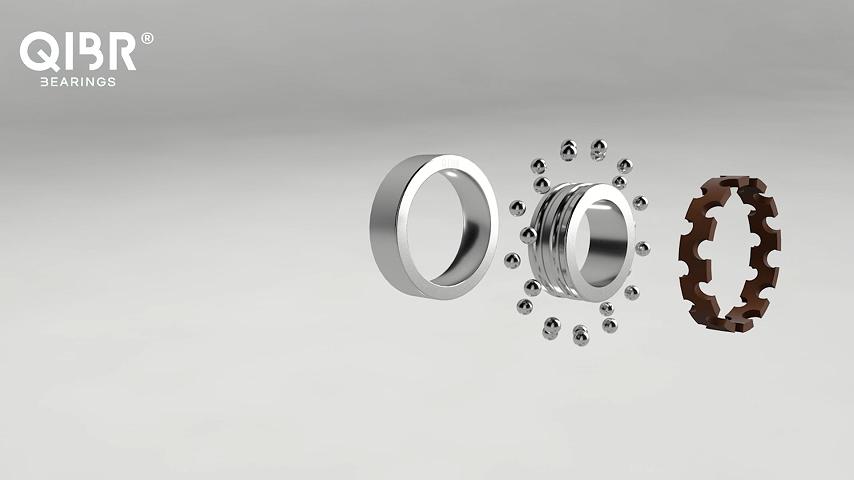

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100, 100Cr6, SUJ2, stainless steel

Brand

QIBR/OEM/Neutral

Applications

Conveyor systems, agricultural machinery, and textile machinery, etc

Inner diameter (d)

5-50 mm

Outer diameter (D)

19-110mm

Mass

0.009-1.2 kg

Package

Standard Export Package

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Bore | Mass | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 801 |

|

1320 EKTN9 | 143 KN | 57 KN | 100 mm | 8.3 kg | 215 mm | 47 mm |

| 802 |

|

1320 ETN9 | 143 KN | 57 KN | 100 mm | 8.3 kg | 215 mm | 47 mm |

| 803 |

|

1320 TN9 | 143 KN | 57 KN | 100 mm | 8.3 kg | 215 mm | 47 mm |

| 804 |

|

1320/P5 | 143 KN | 57 KN | 100 mm | 8.3 kg | 215 mm | 47 mm |

| 805 |

|

1320/P6 | 143 KN | 57 KN | 100 mm | 8.3 kg | 215 mm | 47 mm |

| 806 |

|

1320 K | 143 KN | 57 KN | 100 mm | 8.3 kg | 215 mm | 47 mm |

| 807 |

|

2320 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 808 |

|

2320 C3 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 809 |

|

2320 E-2RS1KTN9 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 810 |

|

2320 E-2RS1TN9 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 811 |

|

2320 EKTN9 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 812 |

|

2320 ETN9 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 813 |

|

2320 TN9 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 814 |

|

2320/P5 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 815 |

|

2320/P6 | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 816 |

|

2320 K | 190 KN | 80 KN | 100 mm | 12.5 kg | 215 mm | 73 mm |

| 817 |

|

1222 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 818 |

|

1222 C3 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 819 |

|

1222 E-2RS1KTN9 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 820 |

|

1222 E-2RS1TN9 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 821 |

|

1222 EKTN9 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 822 |

|

1222 ETN9 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 823 |

|

1222 TN9 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 824 |

|

1222/P5 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 825 |

|

1222/P6 | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 826 |

|

1222 K | 88.4 KN | 39 KN | 110 mm | 5.15 kg | 200 mm | 38 mm |

| 827 |

|

2222 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 828 |

|

2222 C3 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 829 |

|

2222 E-2RS1KTN9 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 830 |

|

2222 E-2RS1TN9 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 831 |

|

2222 EKTN9 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 832 |

|

2222 ETN9 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 833 |

|

2222 TN9 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 834 |

|

2222/P5 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 835 |

|

2222/P6 | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 836 |

|

2222 K | 124 KN | 52 KN | 110 mm | 7.1 kg | 200 mm | 53 mm |

| 837 |

|

1322 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 838 |

|

1322 C3 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 839 |

|

1322 E-2RS1KTN9 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 840 |

|

1322 E-2RS1TN9 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 841 |

|

1322 EKTN9 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 842 |

|

1322 ETN9 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 843 |

|

1322 M | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 844 |

|

1322 TN9 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 845 |

|

1322/P5 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 846 |

|

1322/P6 | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 847 |

|

1322 KM | 163 KN | 72 KN | 110 mm | 12 kg | 240 mm | 50 mm |

| 848 |

|

1224 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 849 |

|

1224 C3 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 850 |

|

1224 E-2RS1KTN9 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 851 |

|

1224 E-2RS1TN9 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 852 |

|

1224 EKTN9 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 853 |

|

1224 ETN9 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 854 |

|

1224 M | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 855 |

|

1224 TN9 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 856 |

|

1224/P5 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 857 |

|

1224/P6 | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 858 |

|

1224 KM | 119 KN | 53 KN | 120 mm | 6.75 kg | 215 mm | 42 mm |

| 859 |

|

1226 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 860 |

|

1226 C3 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 861 |

|

1226 E-2RS1KTN9 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 862 |

|

1226 E-2RS1TN9 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 863 |

|

1226 EKTN9 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 864 |

|

1226 ETN9 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 865 |

|

1226 M | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 866 |

|

1226 TN9 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 867 |

|

1226/P5 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 868 |

|

1226/P6 | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

| 869 |

|

13030 | 57.2 KN | 23.6 KN | 150 mm | 7.5 kg | 225 mm | 56 mm |

| 870 |

|

13030 C3 | 57.2 KN | 23.6 KN | 150 mm | 7.5 kg | 225 mm | 56 mm |

| 871 |

|

13030 E-2RS1TN9 | 57.2 KN | 23.6 KN | 150 mm | 7.5 kg | 225 mm | 56 mm |

| 872 |

|

13030 TN9 | 57.2 KN | 23.6 KN | 150 mm | 7.5 kg | 225 mm | 56 mm |

| 873 |

|

13030/P5 | 57.2 KN | 23.6 KN | 150 mm | 7.5 kg | 225 mm | 56 mm |

| 874 |

|

13030/P6 | 57.2 KN | 23.6 KN | 150 mm | 7.5 kg | 225 mm | 56 mm |

| 875 |

|

13036 | 95.6 KN | 40 KN | 180 mm | 16 kg | 280 mm | 74 mm |

| 876 |

|

13036 E-2RS1TN9 | 95.6 KN | 40 KN | 180 mm | 16 kg | 280 mm | 74 mm |

| 877 |

|

13036 TN9 | 95.6 KN | 40 KN | 180 mm | 16 kg | 280 mm | 74 mm |

| 878 |

|

13036/P5 | 95.6 KN | 40 KN | 180 mm | 16 kg | 280 mm | 74 mm |

| 879 |

|

13036/P6 | 95.6 KN | 40 KN | 180 mm | 16 kg | 280 mm | 74 mm |

| 880 |

|

13940 | 60.5 KN | 29 KN | 200 mm | 10.5 kg | 280 mm | 60 mm |

| 881 |

|

13940 E-2RS1TN9 | 60.5 KN | 29 KN | 200 mm | 10.5 kg | 280 mm | 60 mm |

| 882 |

|

13940 TN9 | 60.5 KN | 29 KN | 200 mm | 10.5 kg | 280 mm | 60 mm |

| 883 |

|

13940/P5 | 60.5 KN | 29 KN | 200 mm | 10.5 kg | 280 mm | 60 mm |

| 884 |

|

13940/P6 | 60.5 KN | 29 KN | 200 mm | 10.5 kg | 280 mm | 60 mm |

| 885 |

|

13944 | 60.5 KN | 30.5 KN | 220 mm | 11 kg | 300 mm | 60 mm |

| 886 |

|

13944 E-2RS1TN9 | 60.5 KN | 30.5 KN | 220 mm | 11 kg | 300 mm | 60 mm |

| 887 |

|

13944 TN9 | 60.5 KN | 30.5 KN | 220 mm | 11 kg | 300 mm | 60 mm |

| 888 |

|

13944/P5 | 60.5 KN | 30.5 KN | 220 mm | 11 kg | 300 mm | 60 mm |

| 889 |

|

13944/P6 | 60.5 KN | 30.5 KN | 220 mm | 11 kg | 300 mm | 60 mm |

| 890 |

|

13948 | 60.5 KN | 32 KN | 240 mm | 11.5 kg | 320 mm | 60 mm |

| 891 |

|

13948 E-2RS1TN9 | 60.5 KN | 32 KN | 240 mm | 11.5 kg | 320 mm | 60 mm |

| 892 |

|

13948 TN9 | 60.5 KN | 32 KN | 240 mm | 11.5 kg | 320 mm | 60 mm |

| 893 |

|

13948/P5 | 60.5 KN | 32 KN | 240 mm | 11.5 kg | 320 mm | 60 mm |

| 894 |

|

13948/P6 | 60.5 KN | 32 KN | 240 mm | 11.5 kg | 320 mm | 60 mm |

| 895 |

|

1226 KM | 127 KN | 58.5 KN | 130 mm | 8.3 kg | 230 mm | 46 mm |

Features and advantages of QIBR self-aligning ball bearings

QIBR self-aligning ball bearings have solved multiple key problems in various fields, which are mainly reflected in the following aspects:

1. Automatic self-aligning function

The biggest feature of QIBR self-aligning ball bearings is that they can automatically align. Because the relative position of the raceways of the inner and outer rings has a certain angle (that is, the raceway of the outer ring is spherical). When the shaft or bearing seat is relatively offset, the contact surface of the ball and the raceway will automatically adjust to ensure that the bearing keeps stable working state and reduce the wear caused by angular error.

2. Carrying capacity

QIBR self-aligning ball bearings have a relatively strong carrying capacity. It can withstand certain radial loads and axial loads.

3. Strong adaptability

QIBR self-aligning ball bearings are particularly suitable for occasions where there is an axial deviation during the process of installation due to their self-aligning characteristics. For example, the bending of the shaft, improper installation of the bearing seat, etc., these situations may cause angular deviations in the bearing, but the self-aligning ball bearing can effectively compensate for these problems and maintain smooth operation.

4. Structural features

QIBR self-aligning ball bearings are double-row design with two rows of ball cages, which can withstand large radial loads.

The performance improvement and solutions of QIBR self-aligning ball bearing

1. Lubricant optimization: Select appropriate lubricating oil or grease, and make appropriate additions and blends to reduce friction and improve wear resistance. The usage of synthetic lubricants or nano-lubricants can significantly improve the efficiency and life of bearings.

2. Raceway optimization: Optimize the raceway geometry of the inner and outer rings, such as increasing the raceway accuracy, improving surface finish, reducing friction, and reducing energy loss, thereby improving the operating efficiency of the bearing.

3. Improve quality of rolling element : Reduce friction and wear by improving the surface finish and hardness of the rolling elements. The usage of high-precision rolling elements (such as ceramics) can significantly improve the running performance of the bearing.

4. Cage design optimization: Adopt a more optimized cage structure, such as using high temperature resistant and corrosion resistant materials and designs, to improve the durability of the cage and the stability of the bearing.

Main application areas of QIBR self-aligning ball bearings

Engine and transmission system

In the engine and transmission system of the car, the self-aligning ball bearing can be used to adapt to the shaft misalignment caused by the vibration or thermal expansion of the engine and other parts.

Fans, blowers and pumps

Since these equipments often have shaft bending or installation errors, the usage of self-aligning ball bearings can reduce maintenance costs and extend the life of the equipments.

Vibrating screen

In the mining industry, self-aligning ball bearings are widely used in equipments such as vibrating screens. Vibrating screens need to operate under high load and high vibration working conditions. Self-aligning ball bearings can effectively alleviate the shaft misalignment and offset problems caused by equipment vibration.

Railway vehicle bearings

In railway vehicles, self-aligning ball bearings can cope with problems such as uneven tracks and wheel offsets to ensure the smoothness and reliability of vehicle operation.