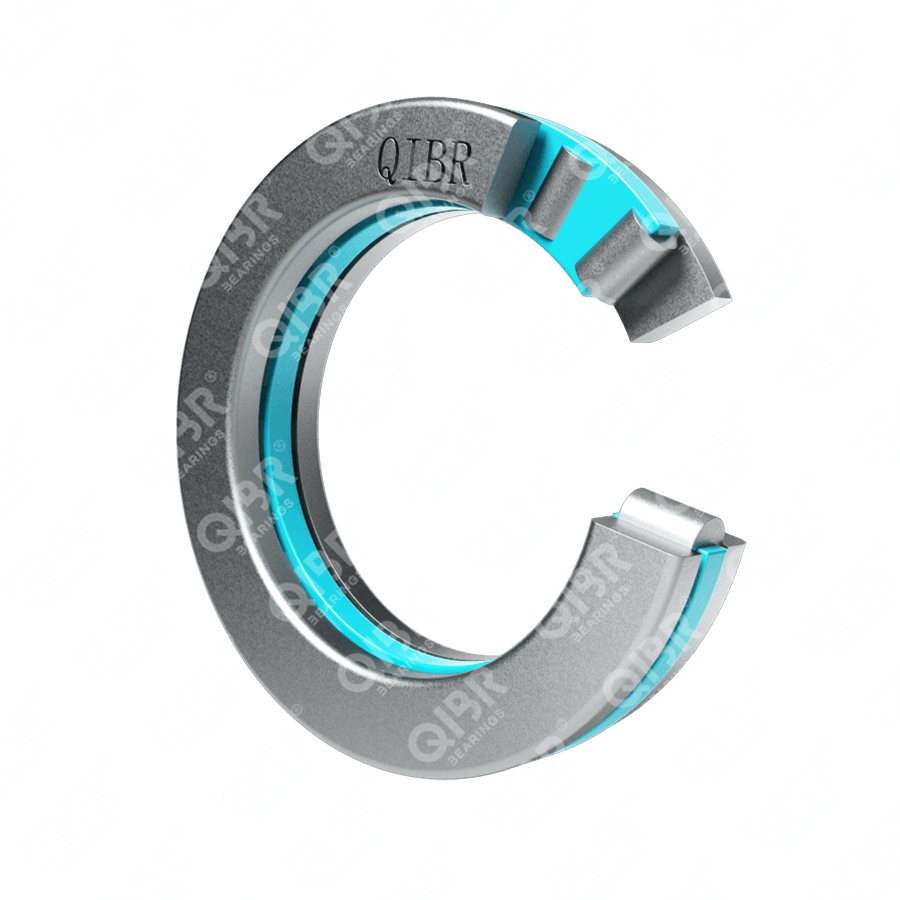

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100/100Cr6/SUJ2/Stainless Steel

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

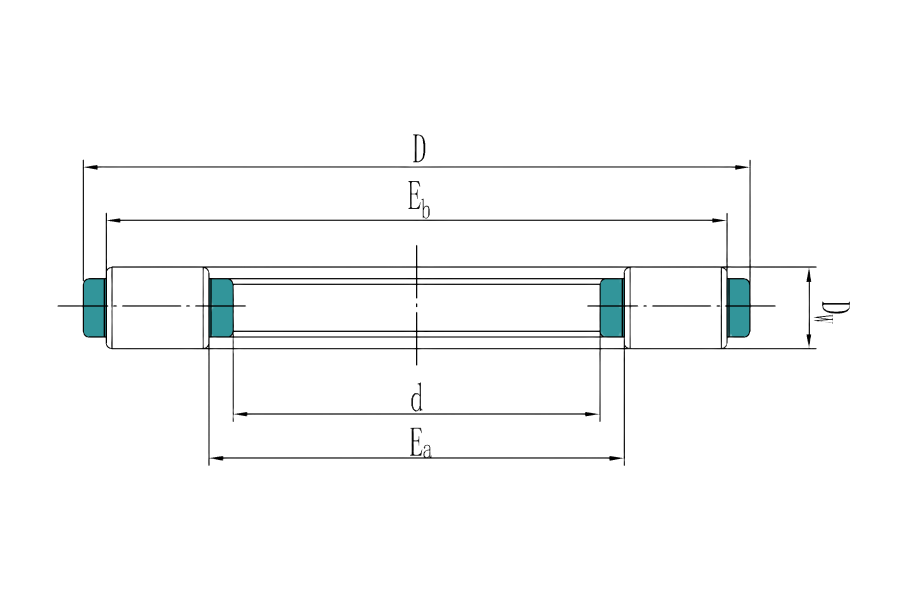

Inner diameter (d)

15~320mm

Outer diameter (D)

20~350mm

Applications

Mainly used in oil drilling rigs, iron and steel machinery

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Bore | Limiting speed | Mass | Outer diameter (D) |

|---|---|---|---|---|---|---|---|---|

| 101 |

|

89314 M | 186 KN | 800 KN | 70 mm | 2800 rpm | 1.8 kg | 125 mm |

| 102 |

|

89314 TN | 186 KN | 800 KN | 70 mm | 2600 rpm | 1.8 kg | 125 mm |

| 103 |

|

89314M/P5 | 186 KN | 800 KN | 70 mm | 2800 rpm | 1.8 kg | 125 mm |

| 104 |

|

81115 | 83 KN | 335 KN | 75 mm | 1900 rpm | 0.39 kg | 100 mm |

| 105 |

|

81115 M | 83 KN | 335 KN | 75 mm | 2800 rpm | 0.39 kg | 100 mm |

| 106 |

|

81115 TN | 83 KN | 335 KN | 75 mm | 3200 rpm | 0.39 kg | 100 mm |

| 107 |

|

81115M/P5 | 83 KN | 335 KN | 75 mm | 3500 rpm | 0.39 kg | 100 mm |

| 108 |

|

81215 | 137 KN | 490 KN | 75 mm | 1900 rpm | 0.8 kg | 110 mm |

| 109 |

|

81215 M | 137 KN | 490 KN | 75 mm | 2100 rpm | 0.8 kg | 110 mm |

| 110 |

|

81215 TN | 137 KN | 490 KN | 75 mm | 2400 rpm | 0.8 kg | 110 mm |

| 111 |

|

81215M/P5 | 137 KN | 490 KN | 75 mm | 2600 rpm | 0.8 kg | 110 mm |

| 112 |

|

81116M/P5 | 81.5 KN | 335 KN | 80 mm | 3300 rpm | 0.4 kg | 105 mm |

| 113 |

|

81116 | 81.5 KN | 335 KN | 80 mm | 2400 rpm | 0.4 kg | 105 mm |

| 114 |

|

81116 M | 81.5 KN | 335 KN | 80 mm | 2700 rpm | 0.4 kg | 105 mm |

| 115 |

|

81116 TN | 81.5 KN | 335 KN | 80 mm | 3000 rpm | 0.4 kg | 105 mm |

| 116 |

|

81216 | 160 KN | 610 KN | 80 mm | 1900 rpm | 0.9 kg | 115 mm |

| 117 |

|

81216 M | 160 KN | 610 KN | 80 mm | 2100 rpm | 0.9 kg | 115 mm |

| 118 |

|

81216 TN | 160 KN | 610 KN | 80 mm | 2400 rpm | 0.9 kg | 115 mm |

| 119 |

|

81216M/P5 | 160 KN | 610 KN | 80 mm | 2600 rpm | 0.9 kg | 115 mm |

| 120 |

|

89316 | 240 KN | 1060 KN | 80 mm | 2200 rpm | 2.35 kg | 140 mm |

| 121 |

|

89316 M | 240 KN | 1060 KN | 80 mm | 2100 rpm | 2.35 kg | 140 mm |

| 122 |

|

89316 TN | 240 KN | 1060 KN | 80 mm | 2400 rpm | 2.35 kg | 140 mm |

| 123 |

|

89316M/P5 | 240 KN | 1060 KN | 80 mm | 2600 rpm | 2.35 kg | 140 mm |

| 124 |

|

89416 | 440 KN | 1730 KN | 80 mm | 1400 rpm | 7.05 kg | 170 mm |

| 125 |

|

89416 M | 440 KN | 1730 KN | 80 mm | 1800 rpm | 7.05 kg | 170 mm |

| 126 |

|

89416 TN | 440 KN | 1730 KN | 80 mm | 2200 rpm | 7.05 kg | 170 mm |

| 127 |

|

89416M/P5 | 440 KN | 1730 KN | 80 mm | 2800 rpm | 7.05 kg | 170 mm |

| 128 |

|

81117 | 88 KN | 365 KN | 85 mm | 2100 rpm | 0.42 kg | 110 mm |

| 129 |

|

81117 M | 88 KN | 365 KN | 85 mm | 1600 rpm | 0.42 kg | 110 mm |

| 130 |

|

81117 TN | 88 KN | 365 KN | 85 mm | 3000 rpm | 0.42 kg | 110 mm |

| 131 |

|

81117M/P5 | 88 KN | 365 KN | 85 mm | 3600 rpm | 0.42 kg | 110 mm |

| 132 |

|

81217 | 170 KN | 640 KN | 85 mm | 1800 rpm | 1.2 kg | 125 mm |

| 133 |

|

81217 M | 170 KN | 640 KN | 85 mm | 2000 rpm | 1.2 kg | 125 mm |

| 134 |

|

81217 TN | 170 KN | 640 KN | 85 mm | 2200 rpm | 1.2 kg | 125 mm |

| 135 |

|

81217M/P5 | 170 KN | 640 KN | 85 mm | 2400 rpm | 1.2 kg | 125 mm |

| 136 |

|

81118 | 110 KN | 450 KN | 90 mm | 2000 rpm | 0.62 kg | 120 mm |

| 137 |

|

81118 M | 110 KN | 450 KN | 90 mm | 2300 rpm | 0.62 kg | 120 mm |

| 138 |

|

81118 TN | 110 KN | 450 KN | 90 mm | 2600 rpm | 0.62 kg | 120 mm |

| 139 |

|

81118M/P5 | 110 KN | 450 KN | 90 mm | 2800 rpm | 0.62 kg | 120 mm |

| 140 |

|

81218 | 232 KN | 865 KN | 90 mm | 1600 rpm | 1.75 kg | 135 mm |

| 141 |

|

81218 M | 232 KN | 865 KN | 90 mm | 1800 rpm | 1.75 kg | 135 mm |

| 142 |

|

81218 TN | 232 KN | 865 KN | 90 mm | 2000 rpm | 1.75 kg | 135 mm |

| 143 |

|

81218M/P5 | 232 KN | 865 KN | 90 mm | 2200 rpm | 1.75 kg | 135 mm |

| 144 |

|

81120 | 156 KN | 630 KN | 100 mm | 1900 rpm | 0.95 kg | 135 mm |

| 145 |

|

81120 M | 156 KN | 630 KN | 100 mm | 2200 rpm | 0.95 kg | 135 mm |

| 146 |

|

81120 TN | 156 KN | 630 KN | 100 mm | 2400 rpm | 0.95 kg | 135 mm |

| 147 |

|

81120M/P5 | 156 KN | 630 KN | 100 mm | 2600 rpm | 0.95 kg | 135 mm |

| 148 |

|

81220 | 270 KN | 1060 KN | 100 mm | 1400 rpm | 2.2 kg | 150 mm |

| 149 |

|

81220 M | 270 KN | 1060 KN | 100 mm | 1600 rpm | 2.2 kg | 150 mm |

| 150 |

|

81220 TN | 270 KN | 1060 KN | 100 mm | 1800 rpm | 2.2 kg | 150 mm |

| 151 |

|

81220M/P5 | 270 KN | 1060 KN | 100 mm | 2000 rpm | 2.2 kg | 150 mm |

| 152 |

|

89320 | 300 KN | 1370 KN | 100 mm | 1700 rpm | 4.55 kg | 170 mm |

| 153 |

|

89320 M | 300 KN | 1370 KN | 100 mm | 1900 rpm | 4.55 kg | 170 mm |

| 154 |

|

89320 TN | 300 KN | 1370 KN | 100 mm | 2100 rpm | 4.55 kg | 170 mm |

| 155 |

|

89320M/P5 | 300 KN | 1370 KN | 100 mm | 2300 rpm | 4.55 kg | 170 mm |

| 156 |

|

81122 | 163 KN | 680 KN | 110 mm | 1800 rpm | 1.05 kg | 145 mm |

| 157 |

|

81122 M | 163 KN | 680 KN | 110 mm | 2000 rpm | 1.05 kg | 145 mm |

| 158 |

|

81122 TN | 163 KN | 680 KN | 110 mm | 2200 rpm | 1.05 kg | 145 mm |

| 159 |

|

81122M/P5 | 163 KN | 680 KN | 110 mm | 2400 rpm | 1.05 kg | 145 mm |

| 160 |

|

81222TN | 260 KN | 1000 KN | 110 mm | 1700 rpm | 2.3 kg | 160 mm |

| 161 |

|

89322 | 400 KN | 1830 KN | 110 mm | 1500 rpm | 6.7 kg | 190 mm |

| 162 |

|

89322 M | 400 KN | 1830 KN | 110 mm | 1700 rpm | 6.7 kg | 190 mm |

| 163 |

|

89322 TN | 400 KN | 1830 KN | 110 mm | 1800 rpm | 6.7 kg | 190 mm |

| 164 |

|

89322M/P5 | 400 KN | 1830 KN | 110 mm | 2000 rpm | 6.7 kg | 190 mm |

| 165 |

|

81124 | 170 KN | 735 KN | 120 mm | 1700 rpm | 1.1 kg | 155 mm |

| 166 |

|

81124 M | 170 KN | 735 KN | 120 mm | 2000 rpm | 1.1 kg | 155 mm |

| 167 |

|

81124 TN | 170 KN | 735 KN | 120 mm | 2200 rpm | 1.1 kg | 155 mm |

| 168 |

|

81124M/P5 | 170 KN | 735 KN | 120 mm | 2400 rpm | 1.1 kg | 155 mm |

| 169 |

|

81224 | 255 KN | 1000 KN | 120 mm | 1300 rpm | 2.55 kg | 170 mm |

| 170 |

|

81224 M | 255 KN | 1000 KN | 120 mm | 1400 rpm | 2.55 kg | 170 mm |

| 171 |

|

81224 TN | 255 KN | 1000 KN | 120 mm | 1600 rpm | 2.55 kg | 170 mm |

| 172 |

|

81224M/P5 | 255 KN | 1000 KN | 120 mm | 1700 rpm | 2.55 kg | 170 mm |

| 173 |

|

89324 | 510 KN | 2360 KN | 120 mm | 1200 rpm | 9.45 kg | 210 mm |

| 174 |

|

89324 M | 510 KN | 2360 KN | 120 mm | 1300 rpm | 9.45 kg | 210 mm |

| 175 |

|

89324 TN | 510 KN | 2360 KN | 120 mm | 1500 rpm | 9.45 kg | 210 mm |

| 176 |

|

89324M/P5 | 510 KN | 2360 KN | 120 mm | 1600 rpm | 9.45 kg | 210 mm |

| 177 |

|

81126 | 200 KN | 880 KN | 130 mm | 1500 rpm | 1.65 kg | 170 mm |

| 178 |

|

81126 M | 200 KN | 880 KN | 130 mm | 1700 rpm | 1.65 kg | 170 mm |

| 179 |

|

81126 TN | 200 KN | 880 KN | 130 mm | 1900 rpm | 1.65 kg | 170 mm |

| 180 |

|

81126M/P5 | 200 KN | 880 KN | 130 mm | 2000 rpm | 1.65 kg | 170 mm |

| 181 |

|

81226 | 380 KN | 1460 KN | 130 mm | 1400 rpm | 4 kg | 190 mm |

| 182 |

|

81226 M | 380 KN | 1460 KN | 130 mm | 1400 rpm | 4 kg | 190 mm |

| 183 |

|

81226 TN | 380 KN | 1460 KN | 130 mm | 1400 rpm | 4 kg | 190 mm |

| 184 |

|

81226M/P5 | 380 KN | 1460 KN | 130 mm | 1400 rpm | 4 kg | 190 mm |

| 185 |

|

81128 | 208 KN | 930 KN | 140 mm | 1400 rpm | 1.9 kg | 180 mm |

| 186 |

|

81128 M | 208 KN | 930 KN | 140 mm | 1600 rpm | 1.9 kg | 180 mm |

| 187 |

|

81128 TN | 208 KN | 930 KN | 140 mm | 1800 rpm | 1.9 kg | 180 mm |

| 188 |

|

81128M/P5 | 208 KN | 930 KN | 140 mm | 2000 rpm | 1.9 kg | 180 mm |

| 189 |

|

81228 | 360 KN | 1400 KN | 140 mm | 1400 rpm | 5.05 kg | 200 mm |

| 190 |

|

81228 M | 360 KN | 1400 KN | 140 mm | 1400 rpm | 5.05 kg | 200 mm |

| 191 |

|

81228 TN | 360 KN | 1400 KN | 140 mm | 1400 rpm | 5.05 kg | 200 mm |

| 192 |

|

81228M/P5 | 360 KN | 1400 KN | 140 mm | 1400 rpm | 5.05 kg | 200 mm |

| 193 |

|

81130 | 212 KN | 1000 KN | 150 mm | 1400 rpm | 2.2 kg | 190 mm |

| 194 |

|

81130 M | 212 KN | 1000 KN | 150 mm | 1500 rpm | 2.2 kg | 190 mm |

| 195 |

|

81130 TN | 212 KN | 1000 KN | 150 mm | 1700 rpm | 2.2 kg | 190 mm |

| 196 |

|

81130M/P5 | 212 KN | 1000 KN | 150 mm | 1900 rpm | 2.2 kg | 190 mm |

| 197 |

|

81230 | 465 KN | 1900 KN | 150 mm | 1100 rpm | 7.2 kg | 215 mm |

| 198 |

|

81230 M | 465 KN | 1900 KN | 150 mm | 1300 rpm | 7.2 kg | 215 mm |

| 199 |

|

81230 TN | 465 KN | 1900 KN | 150 mm | 1300 rpm | 7.2 kg | 215 mm |

| 200 |

|

81230M/P5 | 465 KN | 1900 KN | 150 mm | 1500 rpm | 7.2 kg | 215 mm |

QIBR thrust cylindrical roller bearings solve several key problems in various fields, which are mainly reflected in the following aspects:

1. High load capacity

Thrust cylindrical roller bearings can withstand large axial loads. Due to the large contact area of the rollers, the bearings can share a larger axial force, especially suitable for high-load working environments.

2. High rigidity

Due to its structural characteristics and the design of the cylindrical rollers, thrust cylindrical roller bearings have high rigidity. It can effectively reduce axial deformation, provide more stable movement and higher load capacity, suitable for high-precision, high-load applications.

3. Good durability

This type of bearing has high durability because its rolling friction characteristics reduce wear on the contact surface. The roller design ensures uniform load distribution and extends the service life of the bearing.

4. Simple maintenance

Due to the simple structure and fewer moving parts of thrust cylindrical roller bearings, they are generally easy to maintain and inspect. Regular lubrication and inspection help to extend their service life.

QIBR thrust cylindrical roller bearing performance improvement and solutions

1. Improve material selection

High-performance materials: Use high-strength, high-wear-resistant materials to improve the durability of bearings.

High-temperature resistant materials: When working in a high-temperature environment, choosing high-temperature resistant materials can maintain the performance of the bearing and prevent material deformation or failure due to excessive temperature.

2. Optimize roller design

Optimize roller shape: By optimizing the geometry and size of the rollers, the bearing's load capacity and working performance can be improved.

Improve the uniformity of roller spacing: Improve the design of the cage to ensure that the rollers maintain a uniform spacing during operation, thereby improving the uniformity of the load distribution of the bearing and reducing local overload and wear.

Increase the number of rollers: Increasing the number of rollers inside the bearing can further improve the bearing's load capacity, especially for high-load bearing occasions.

3. Improve manufacturing accuracy

Higher bearing manufacturing accuracy: Improve the operating accuracy and stability of the bearing by improving processing accuracy, controlling tolerances and optimizing production processes.

4. Optimize lubrication management

Choose the right lubricant: Choose the right lubricant or grease according to the temperature, load and speed of the working environment to ensure that the bearing maintains proper lubrication during operation and reduces friction and wear.

Regular lubrication and maintenance: Check the lubrication status regularly, replace the lubricant or grease in time, avoid lubricant deterioration or contamination, and ensure long-term stable operation of the bearing.

Main application areas of QIBR thrust cylindrical roller bearings

1. Heavy machinery and equipment

Thrust cylindrical roller bearings are widely used in various heavy machinery and equipment, such as:

Mining equipment: such as crushers, screening machines, vibrating screens, etc.

Metallurgical equipment: such as rolling mills, smelting furnaces, etc.

Crane: such as port cranes, large bridge cranes, etc., to bear the axial load of heavy objects.

2. Ships and marine engineering

Thrust cylindrical roller bearings play an important role in the power system of ships and offshore platforms, especially:

Ship propulsion system: bearings used for ship main engines, which can withstand high-load axial forces.

Offshore platform equipment: such as drilling equipment, offshore lifting systems, etc., which withstand large axial pressure and environmental vibration.

3. High-speed railways and rail transit

Thrust cylindrical roller bearings are also used in the field of railway transportation, especially:

EMU/high-speed rail: in the transmission system, used to withstand axial loads at high speeds.

Railway car: in the traction system of the vehicle, as a key component that bears high-strength axial forces.

4. Industrial transmission equipment

Thrust cylindrical roller bearings are widely used in many industrial transmission equipment, especially:

Automobile transmission systems: such as transmissions, differentials and other components, need to bear large axial loads.

Mechanical transmission devices: such as gearboxes, pumps, compressors, etc., all require thrust bearings to support axial loads.