QACB30.1541.8H7

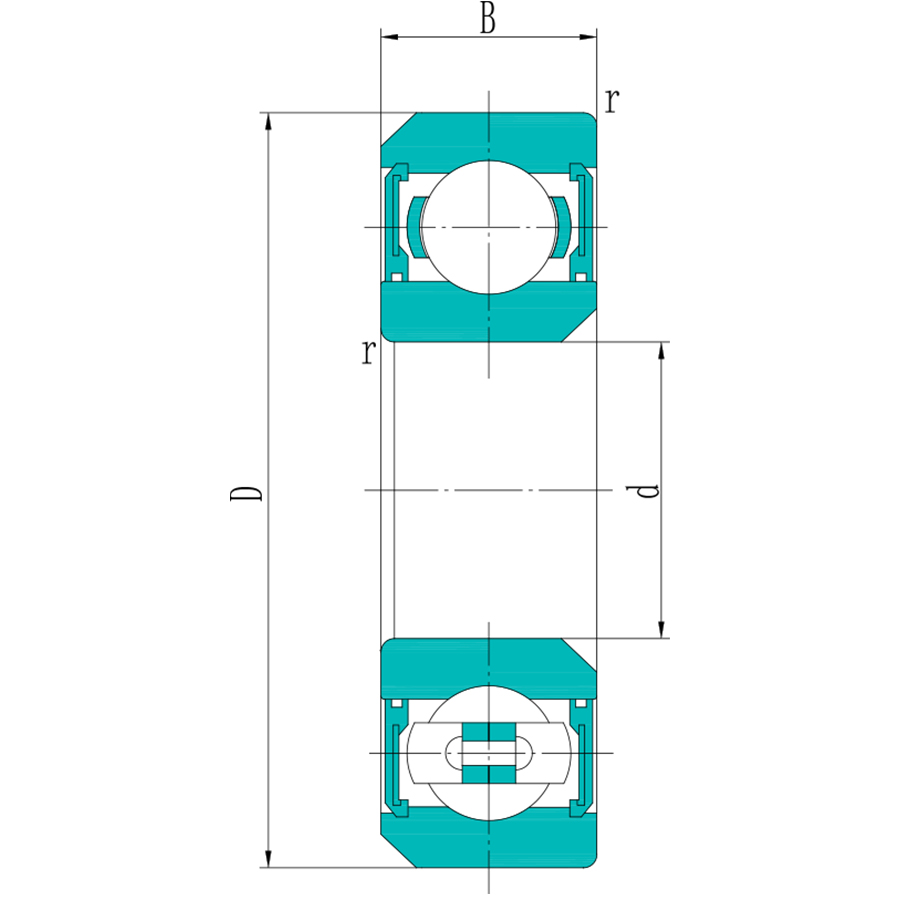

- Outer diameter (D)

- 41.8 mm

- Inner diameter (d)

- 30.15 mm

- Overall width (B)

- 7 mm

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Bicycle bearing series Seris - QACB30.1541.8H7

Description

QIBR - QACB30.1541.8H7 Bicycle Bearing Advantages and Applications

QACB30.1541.8H7 Bicycle Bearing, high speed, lightweight, Inner diameter (d) is 30.15 mm, Outer diameter (D) is 41.8 mm, Overall width (B) is 7 mm, Weight is 0.023 kg, suitable for mountain bikes, road bikes, city bikes and electric bikes, etc., and is the most widely used bearing in working conditions with high speed requirements.

QIBR - QACB30.1541.8H7 Bicycle Bearing Characteristics

QACB30.1541.8H7 Bicycle Bearing, long life, high reliability, easy installation and maintenance. QACB30.1541.8H7 Bicycle Bearing, can bear radial load and certain axial load at the same time, suitable for mechanical equipment with high precision requirements.

QACB30.1541.8H7 Bicycle Bearing Product Product Features and Advantages

Reduced Friction: Capable of simultaneously bearing large radial and axial loads, suitable for various load conditions.

Durability: Made from wear-resistant materials, capable of withstanding heavy loads while significantly reducing rotational resistance under load conditions.

Lightweight Design: Low-density design reduces the overall weight of the bicycle, enhancing handling and riding comfort.

Precise Steering: Low friction coefficient, resulting in low noise during operation, suitable for high-speed applications.

Application: Widely used in key parts such as wheels, bottom brackets, pedals, frames, derailleurs, sports and racing bicycles, and electric bicycles.

QIBR - QACB30.1541.8H7 Bicycle Bearing Optimization

Modular Design: Bearings are designed modularly according to customer needs, making replacement and maintenance easier.

High-Performance Materials: Lubricants can be chosen based on bearing operational needs, such as SKF LGED 2, Mobil SHC Polyrex 102 EM, etc.

Sealing Materials: Different sealing materials can be chosen based on customer needs, such as rubber, POM, polyurethane, etc.

Lubricants: Suitable lubricants are selected based on bearing working conditions and different bearing locations, such as SKF LGLT 2, Klüber ISOFLEX TOPAS NB 52, Multemp SRL, etc.

Further Customization: QIBR can design and optimize bearings based on customer working conditions and requirements.

QIBR - QACB30.1541.8H7 Bicycle Bearing Quality Control

Dimension measurement: Multiple professional high-precision instruments are used to measure various dimensions of the bearing, with the highest precision reaching 0.001mm.

Rotation accuracy: A dial indicator is used to measure minor defects or deviations on the bearing surface, with measurement accuracy up to 0.001mm.

Hardness measurement: The surface hardness of the bearing is measured with a hardness tester, with measurement accuracy up to ±0.5 HRC.

Metallographic analysis: The internal metallographic structure of the metal is analyzed using a professional metallographic microscope.

Geometric tolerance: A contour instrument is used to measure the geometric shape and relative position of the bearing.

Noise monitoring: Vibration instruments are used to monitor vibration during operation and obtain noise data.

Raw material control: Steel and parts are procured from suppliers with ISO 14001 certification, ensuring product stability while promoting sustainable development.

Features & Benefits

Bicycle bearings are essential components that enable smooth rotation in various parts of the bike, such as the wheels, bottom bracket, headset, and pedals. They reduce friction and wear between moving parts, ensuring efficient transfer of energy and a comfortable ride. Bearings come in different types, including ball bearings, roller bearings, and cartridge bearings, each suited for specific applications. Proper maintenance and lubrication are crucial to extend their lifespan and ensure optimal performance. Selecting the right bearing type and quality can significantly impact the bike's efficiency and longevity.

Downloads