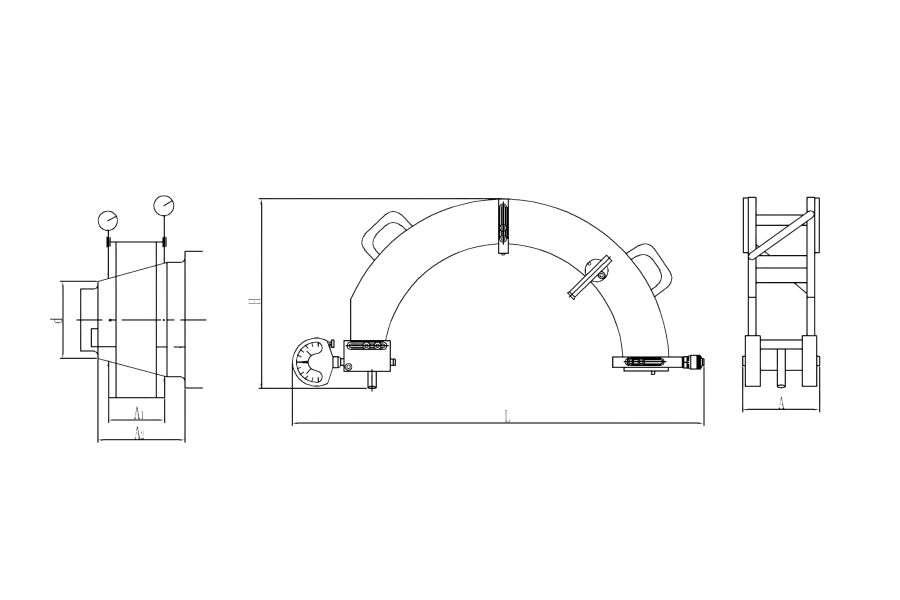

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Product number

DMB 4/5.5-DMB 32/36

Taper MIN diameter (d)

40mm-320mm

Taper MAX diameter (d)

55mm-360mm

Width

36mm-114mm

Distance (A1)

18mm-90mm

Height (H)

140mm-290mm

Mass taper gauge

2.5kg-10.0kg

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN/VDEh,DIN/VDEh

Brand

QIBR/OEM/Neutral

Package

Standard Export Package

| NO. | Product | Product Number | Height (H) | Mass | Taper MAX diameter (d) | Taper MIN diameter (d) | Width (A) |

|---|---|---|---|---|---|---|---|

| 1 |

|

DMB 4/5.5 | 140 mm | 2.5 kg | 55 mm | 40 mm | 36 mm |

| 2 |

|

DMB 5/8.5 | 160 mm | 2.5 kg | 85 mm | 50 mm | 38 mm |

| 3 |

|

DMB 8/12 | 190 mm | 3.0 kg | 120 mm | 80 mm | 48 mm |

| 4 |

|

DMB 12/16 | 190 mm | 3.5 kg | 160 mm | 120 mm | 58 mm |

| 5 |

|

DMB 16/20 | 190 mm | 4.5 kg | 200 mm | 160 mm | 74 mm |

| 6 |

|

DMB 20/24 | 215 mm | 5.5 kg | 240 mm | 200 mm | 84 mm |

| 7 |

|

DMB 24/28 | 240 mm | 7.0 kg | 280 mm | 240 mm | 99 mm |

| 8 |

|

DMB 28/32 | 265 mm | 8.5 kg | 320 mm | 280 mm | 114 mm |

| 9 |

|

DMB 32/36 | 290 mm | 10 kg | 360 mm | 320 mm | 114 mm |

Functions of DMB taper gauges

1. Dimension Measurement

Ensures that the dimensions of bearings conform to design specifications.

2. Angle inspection

Verifies that the taper angles meet production requirements, preventing bearing failures caused by assembly errors.

3. Quality control

Serves as part of production quality control, helping to check and verify the accuracy of products.

Measurement using DMB taper gauges

The gauge pins and the radial stops can be set to measure any taper angle between 0°and 6°and any diameter within the range of the gauge. Markings on the scales show the set-tings for 1:12 and 1:30 tapers.