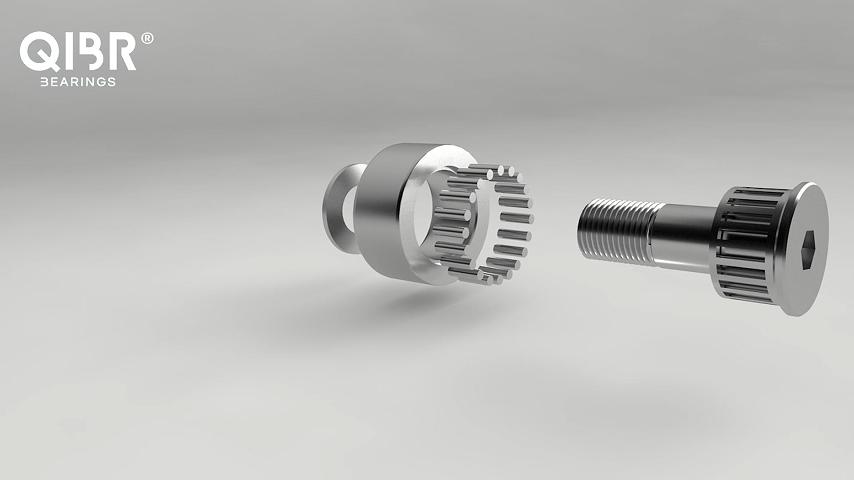

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100/100Cr6/SUJ2/Stainless Steel

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Outer diameter

16~90mm

Total length

28~100mm

Applications

Automotive Industry, Material Handling Equipment, Construction Machinery, Agricultural Equipment, etc

| NO. | Product | Product Number | Outer diameter (D) | Width (B) | Attachment diameter (d) | Length shank on stud (B1) | Length thread (G1) | Pitch of screws |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

CCF-1 1/2-S | 1.500 inch | 0.875 inch | 0.625 inch | 1 1/2 inch | 3/4 inch | 5/8-18 |

| 2 |

|

CCF-1 1/2-SB | 1.500 inch | 0.875 inch | 0.625 inch | 1 1/2 inch | 3/4 inch | 5/8-18 |

| 3 |

|

CCF-1 1/4-S | 1.250 inch | 0.750 inch | 0.500 inch | 1 1/4 inch | 5/8 inch | 1/2-20 |

| 4 |

|

CCF-1 1/4-SB | 1.250 inch | 0.750 inch | 0.500 inch | 1 1/4 inch | 5/8 inch | 1/2-20 |

| 5 |

|

CCF-1 1/8-S | 1.125 inch | 0.625 inch | 0.4375 inch | 1 inch | 1/2 inch | 7/16-20 |

| 6 |

|

CCF-1 1/8-SB | 1.125 inch | 0.625 inch | 0.4375 inch | 1 inch | 1/2 inch | 7/16-20 |

| 7 |

|

CCF-1 3/4-S | 1.750 inch | 1.000 inch | 0.750 inch | 1 3/4 inch | 7/8 inch | 3/4-16 |

| 8 |

|

CCF-1 3/4-SB | 1.750 inch | 1.000 inch | 0.750 inch | 1 3/4 inch | 7/8 inch | 3/4-16 |

| 9 |

|

CCF-1 3/8-S | 1.375 inch | 0.750 inch | 0.500 inch | 1 1/4 inch | 5/8 inch | 1/2-20 |

| 10 |

|

CCF-1 3/8-SB | 1.375 inch | 0.750 inch | 0.500 inch | 1 1/4 inch | 5/8 inch | 1/2-20 |

| 11 |

|

CCF-1 5/8-S | 1.625 inch | 0.875 inch | 0.625 inch | 1 1/2 inch | 3/4 inch | 5/8-18 |

| 12 |

|

CCF-1 5/8-SB | 1.625 inch | 0.875 inch | 0.625 inch | 1 1/2 inch | 3/4 inch | 5/8-18 |

| 13 |

|

CCF-1 7/8-S | 1.850 inch | 1.000 inch | 0.750 inch | 1 3/4 inch | 7/8 inch | 3/4-16 |

| 14 |

|

CCF-1 7/8-SB | 1.850 inch | 1.000 inch | 0.750 inch | 1 3/4 inch | 7/8 inch | 3/4-16 |

| 15 |

|

CCF-1-S | 1.000 inch | 0.625 inch | 0.4375 inch | 1 inch | 1/2 inch | 7/16-20 |

| 16 |

|

CCF-1-SB | 1.000 inch | 0.625 inch | 0.4375 inch | 1 inch | 1/2 inch | 7/16-20 |

| 17 |

|

CCF-1/2-N-S | 0.500 inch | 0.344 inch | 0.19 inch | 1/2 inch | 1/4 inch | 10-32 |

| 18 |

|

CCF-1/2-N-SB | 0.500 inch | 0.344 inch | 0.19 inch | 1/2 inch | 1/4 inch | 10-32 |

| 19 |

|

CCF-1/2-S | 0.500 inch | 0.375 inch | 0.190 inch | 5/8 inch | 1/4 inch | 10-32 |

| 20 |

|

CCF-1/2-SB | 0.500 inch | 0.375 inch | 0.190 inch | 5/8 inch | 1/4 inch | 10-32 |

| 21 |

|

CCF-10-S | 10.000 inch | 5.250 inch | 4.250 inch | 10 inch | 4 3/4 inch | 3 1/2-4 |

| 22 |

|

CCF-11/16-S | 0.6875 inch | 0.4375 inch | 0.250 inch | 3/4 inch | 5/16 inch | 1/4-28 |

| 23 |

|

CCF-11/16-SB | 0.6875 inch | 0.4375 inch | 0.250 inch | 3/4 inch | 5/16 inch | 1/4-28 |

| 24 |

|

CCF-2 1/2-S | 2.500 inch | 1.500 inch | 1.000 inch | 2 1/4 inch | 1 1/8 inch | 1-14 |

| 25 |

|

CCF-2 1/2-SB | 2.500 inch | 1.500 inch | 1.000 inch | 2 1/4 inch | 1 1/8 inch | 1-14 |

| 26 |

|

CCF-2 1/4-S | 2.250 inch | 1.250 inch | 0.875 inch | 2 inch | 1 inch | 7/8-14 |

| 27 |

|

CCF-2 1/4-SB | 2.250 inch | 1.250 inch | 0.875 inch | 2 inch | 1 inch | 7/8-14 |

| 28 |

|

CCF-2 3/4-S | 2.750 inch | 1.500 inch | 1.000 inch | 2 1/4 inch | 1 1/8 inch | 1-14 |

| 29 |

|

CCF-2 3/4-SB | 2.750 inch | 1.500 inch | 1.000 inch | 2 1/4 inch | 1 1/8 inch | 1-14 |

| 30 |

|

CCF-2-S | 2.000 inch | 1.250 inch | 0.875 inch | 2 inch | 1 inch | 7/8-14 |

| 31 |

|

CCF-2-SB | 2.000 inch | 1.250 inch | 0.875 inch | 2 inch | 1 inch | 7/8-14 |

| 32 |

|

CCF-3 1/2-S | 3.500 inch | 2.000 inch | 1.375 inch | 2 3/4 inch | 1 3/8 inch | 1 3/8-12 |

| 33 |

|

CCF-3 1/2-SB | 3.500 inch | 2.000 inch | 1.375 inch | 2 3/4 inch | 1 3/8 inch | 1 3/8-12 |

| 34 |

|

CCF-3 1/4-S | 3.250 inch | 1.750 inch | 1.250 inch | 2 1/2 inch | 1 1/4 inch | 1 1/4-12 |

| 35 |

|

CCF-3 1/4-SB | 3.250 inch | 1.750 inch | 1.250 inch | 2 1/2 inch | 1 1/4 inch | 1 1/4-12 |

| 36 |

|

CCF-3-S | 3.000 inch | 1.750 inch | 1.250 inch | 2 1/2 inch | 1 1/4 inch | 1 1/4-12 |

| 37 |

|

CCF-3-SB | 3.000 inch | 1.750 inch | 1.250 inch | 2 1/2 inch | 1 1/4 inch | 1 1/4-12 |

| 38 |

|

CCF-3/4-S | 0.750 inch | 0.500 inch | 0.375 inch | 7/8 inch | 3/8 inch | 3/8-24 |

| 39 |

|

CCF-3/4-SB | 0.750 inch | 0.500 inch | 0.375 inch | 7/8 inch | 3/8 inch | 3/8-24 |

| 40 |

|

CCF-4-S | 4.000 inch | 2.250 inch | 1.500 inch | 3 1/2 inch | 1 1/2 inch | 1 1/2-12 |

| 41 |

|

CCF-4-SB | 4.000 inch | 2.250 inch | 1.500 inch | 3 1/2 inch | 1 1/2 inch | 1 1/2-12 |

| 42 |

|

CCF-5-S | 5.000 inch | 2.750 inch | 2.000 inch | 5 1/16 inch | 2 9/16 inch | 2-12 |

| 43 |

|

CCF-5/8-N-S | 0.625 inch | 0.406 inch | 0.250 inch | 5/8 inch | 5/16 inch | 1/4-28 |

| 44 |

|

CCF-5/8-N-SB | 0.625 inch | 0.406 inch | 0.250 inch | 5/8 inch | 5/16 inch | 1/4-28 |

| 45 |

|

CCF-5/8-S | 0.625 inch | 0.4375 inch | 0.250 inch | 3/4 inch | 5/16 inch | 1/4-28 |

| 46 |

|

CCF-5/8-SB | 0.625 inch | 0.4375 inch | 0.250 inch | 3/4 inch | 5/16 inch | 1/4-28 |

| 47 |

|

CCF-6-S | 6.000 inch | 3.250 inch | 2.500 inch | 6 inch | 3 inch | 2 1/2-12 |

| 48 |

|

CCF-7-S | 7.000 inch | 3.750 inch | 3.000 inch | 7 11/16 inch | 4 1/8 inch | 3-12 |

| 49 |

|

CCF-7/8-S | 0.875 inch | 0.500 inch | 0.375 inch | 7/8 inch | 3/8 inch | 3/8-24 |

| 50 |

|

CCF-7/8-SB | 0.875 inch | 0.500 inch | 0.375 inch | 7/8 inch | 3/8 inch | 3/8-24 |

| 51 |

|

CCF-8-S | 8.000 inch | 4.250 inch | 3.250 inch | 8 1/2 inch | 4 1/4 inch | 3 1/4-4 |

| 52 |

|

CCF-9-S | 9.000 inch | 4.750 inch | 3.750 inch | 9 1/2 inch | 4 3/4 inch | 3 1/2-4 |

| 53 |

|

CCF-9/16-S | 0.5625 inch | 0.375 inch | 0.190 inch | 5/8 inch | 1/4 inch | 10-32 |

| 54 |

|

CCF-9/16-SB | 0.5625 inch | 0.375 inch | 0.190 inch | 5/8 inch | 1/4 inch | 10-32 |

| 55 |

|

CCFE-1 1/2-S | 1.500 inch | 0.875 inch | 1 1/2 inch | 3/4 inch | 5/8-18 | |

| 56 |

|

CCFE-1 1/2-SB | 1.500 inch | 0.875 inch | 1 1/2 inch | 3/4 inch | 5/8-18 | |

| 57 |

|

CCFE-1 1/4-S | 1.250 inch | 0.750 inch | 1 1/4 inch | 5/8 inch | 1/2-20 | |

| 58 |

|

CCFE-1 1/4-SB | 1.250 inch | 0.750 inch | 1 1/4 inch | 5/8 inch | 1/2-20 | |

| 59 |

|

CCFE-1 1/8-S | 1.125 inch | 0.625 inch | 1 inch | 1/2 inch | 7/16-20 | |

| 60 |

|

CCFE-1 1/8-SB | 1.125 inch | 0.625 inch | 1 inch | 1/2 inch | 7/16-20 | |

| 61 |

|

CCFE-1 3/4-S | 1.750 inch | 1.000 inch | 1 3/4 inch | 7/8 inch | 3/4-16 | |

| 62 |

|

CCFE-1 3/4-SB | 1.750 inch | 1.000 inch | 1 3/4 inch | 7/8 inch | 3/4-16 | |

| 63 |

|

CCFE-1 3/8-S | 1.375 inch | 0.750 inch | 1 1/4 inch | 5/8 inch | 1/2-20 | |

| 64 |

|

CCFE-1 3/8-SB | 1.375 inch | 0.750 inch | 1 1/4 inch | 5/8 inch | 1/2-20 | |

| 65 |

|

CCFE-1 5/8-S | 1.625 inch | 0.875 inch | 1 1/2 inch | 3/4 inch | 5/8-18 | |

| 66 |

|

CCFE-1 5/8-SB | 1.625 inch | 0.875 inch | 1 1/2 inch | 3/4 inch | 5/8-18 | |

| 67 |

|

CCFE-1 7/8-S | 1.875 inch | 1.000 inch | 1 3/4 inch | 7/8 inch | 3/4-16 | |

| 68 |

|

CCFE-1 7/8-SB | 1.875 inch | 1.000 inch | 1 3/4 inch | 7/8 inch | 3/4-16 | |

| 69 |

|

CCFE-1-S | 1.000 inch | 0.625 inch | 1 inch | 1/2 inch | 7/16-20 | |

| 70 |

|

CCFE-1-SB | 1.000 inch | 0.625 inch | 1 inch | 1/2 inch | 7/16-20 | |

| 71 |

|

CCFE-1/2-N-S | 0.500 inch | 0.344 inch | 1/2 inch | 1/4 inch | 10-32 | |

| 72 |

|

CCFE-1/2-N-SB | 0.500 inch | 0.344 inch | 1/2 inch | 1/4 inch | 10-32 | |

| 73 |

|

CCFE-1/2-S | 0.500 inch | 0.375 inch | 5/8 inch | 1/4 inch | 10-32 | |

| 74 |

|

CCFE-1/2-SB | 0.500 inch | 0.375 inch | 5/8 inch | 1/4 inch | 10-32 | |

| 75 |

|

CCFE-11/16-S | 0.6875 inch | 0.4375 inch | 3/4 inch | 5/16 inch | 1/4-28 | |

| 76 |

|

CCFE-11/16-SB | 0.6875 inch | 0.4375 inch | 3/4 inch | 5/16 inch | 1/4-28 | |

| 77 |

|

CCFE-2 1/2-S | 2.500 inch | 1.500 inch | 2 1/4 inch | 1 1/8 inch | 1-14 | |

| 78 |

|

CCFE-2 1/2-SB | 2.500 inch | 1.500 inch | 2 1/4 inch | 1 1/8 inch | 1-14 | |

| 79 |

|

CCFE-2 1/4-S | 2.250 inch | 1.250 inch | 2 inch | 1 inch | 7/8-14 | |

| 80 |

|

CCFE-2 1/4-SB | 2.250 inch | 1.250 inch | 2 inch | 1 inch | 7/8-14 | |

| 81 |

|

CCFE-2 3/4-S | 2.750 inch | 1.500 inch | 2 1/4 inch | 1 1/8 inch | 1-14 | |

| 82 |

|

CCFE-2 3/4-SB | 2.750 inch | 1.500 inch | 2 1/4 inch | 1 1/8 inch | 1-14 | |

| 83 |

|

CCFE-2-S | 2.000 inch | 1.250 inch | 2 inch | 1 inch | 7/8-14 | |

| 84 |

|

CCFE-2-SB | 2.000 inch | 1.250 inch | 2 inch | 1 inch | 7/8-14 | |

| 85 |

|

CCFE-3 1/2-S | 3.500 inch | 2.000 inch | 2 3/4 inch | 1 3/8 inch | 1 3/8-12 | |

| 86 |

|

CCFE-3 1/2-SB | 3.500 inch | 2.000 inch | 2 3/4 inch | 1 3/8 inch | 1 3/8-12 | |

| 87 |

|

CCFE-3 1/4-S | 3.250 inch | 1.750 inch | 2 1/2 inch | 1 1/4 inch | 1 1/4-12 | |

| 88 |

|

CCFE-3 1/4-SB | 3.250 inch | 1.750 inch | 2 1/2 inch | 1 1/4 inch | 1 1/4-12 | |

| 89 |

|

CCFE-3-S | 3.000 inch | 1.750 inch | 2 1/2 inch | 1 1/4 inch | 1 1/4-12 | |

| 90 |

|

CCFE-3-SB | 3.000 inch | 1.750 inch | 2 1/2 inch | 1 1/4 inch | 1 1/4-12 | |

| 91 |

|

CCFE-3/4-S | 0.750 inch | 0.500 inch | 7/8 inch | 3/8 inch | 3/8-24 | |

| 92 |

|

CCFE-3/4-SB | 0.750 inch | 0.500 inch | 7/8 inch | 3/8 inch | 3/8-24 | |

| 93 |

|

CCFE-4-S | 4.000 inch | 2.250 inch | 3 1/2 inch | 1 1/2 inch | 1 1/2-12 | |

| 94 |

|

CCFE-4-SB | 4.000 inch | 2.250 inch | 3 1/2 inch | 1 1/2 inch | 1 1/2-12 | |

| 95 |

|

CCFE-5/8-S | 0.625 inch | 0.4375 inch | 3/4 inch | 5/16 inch | 1/4-28 | |

| 96 |

|

CCFE-5/8-SB | 0.625 inch | 0.4375 inch | 3/4 inch | 5/16 inch | 1/4-28 | |

| 97 |

|

CCFE-7/8-S | 0.875 inch | 0.500 inch | 7/8 inch | 3/8 inch | 3/8-24 | |

| 98 |

|

CCFE-7/8-SB | 0.875 inch | 0.500 inch | 7/8 inch | 3/8 inch | 3/8-24 | |

| 99 |

|

CCFE-9/16-S | 0.5625 inch | 0.375 inch | 5/8 inch | 1/4 inch | 10-32 | |

| 100 |

|

CCFE-9/16-SB | 0.5625 inch | 0.375 inch | 5/8 inch | 1/4 inch | 10-32 |

Features and advantages of QIBR cam followers cylindrical roller bearings

Cam followers cylindrical roller bearings solve several key problems in various fields, mainly reflected in the following aspects:

1. Easy installation

This type of bearing uses a bolt fixing method, allowing users to quickly install or remove it without complicated alignment operations. This makes it more convenient for maintenance and replacement, suitable for large equipment or applications with high maintenance demands.

2. High reliability

Cam followers cylindrical roller bearings typically offer strong durability, working stably in harsh environments. Their structural design reduces wear, friction, and fatigue damage, extending service life.

3. Compact structure

Cam followers cylindrical roller bearings are usually designed to be compact, making them suitable for use in space-limited equipment.

4. Easy maintenance

Due to their simple structure and easy installation method, cam followers cylindrical roller bearings generally have lower maintenance costs and are easier to replace and inspect.

Performance improvement and solutions for cam followers cylindrical roller bearings

1. Optimizing lubricants: Selecting the right oil or grease and adding and blending it appropriately can reduce friction and improve wear resistance. Using synthetic lubricants or nano lubricants can significantly improve bearing efficiency and longevity.

2. Optimizing raceways: Improving the geometry of the inner and outer ring raceways, such as increasing raceway precision and enhancing surface finish, reduces friction and energy loss, thus improving bearing operation efficiency.

3. Using high-temperature and corrosion-resistant sealing materials

To adapt to special environments like high temperatures and high humidity, using more heat-resistant and corrosion-resistant sealing materials can significantly improve bearing reliability.

4. Corrosion-resistant design: For demanding work environments (such as marine, chemical, etc.), stainless steel, corrosion-resistant coatings, or surface treatment technologies can be used to improve the bearing's anti-corrosion performance.

Main application fields of cam followers cylindrical roller bearings

1. Conveyor systems

Cam followers cylindrical roller bearings are commonly used in conveyor belts and roller conveyor systems to help transport various goods and items. The rollers reduce friction, making the transportation process more efficient and smooth.

2. Automation equipment

In automated production lines, cam followers cylindrical roller bearings are widely used in logistics conveyors, assembly lines, and other equipment, playing a role in guiding, supporting, and pushing items.

3. Wheels and chassis components

In automotive chassis design, cam followers cylindrical roller bearings can serve as part of the wheel support structure, helping reduce friction between the tires and the ground, thus improving vehicle motion efficiency.

4. Automated warehousing

In automated warehouses, cam followers cylindrical roller bearings can work in conjunction with automated handling equipment to improve the precision and speed of item transportation.