32020X

- Inner diameter:

- 100 mm

- Outer diameter:

- 150 mm

- Width:

- 32 mm

- Mass:

- 1.89 kg

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - 32020X

Description

QIBR - 32020X Tapered Roller Bearing Advantages and Applications

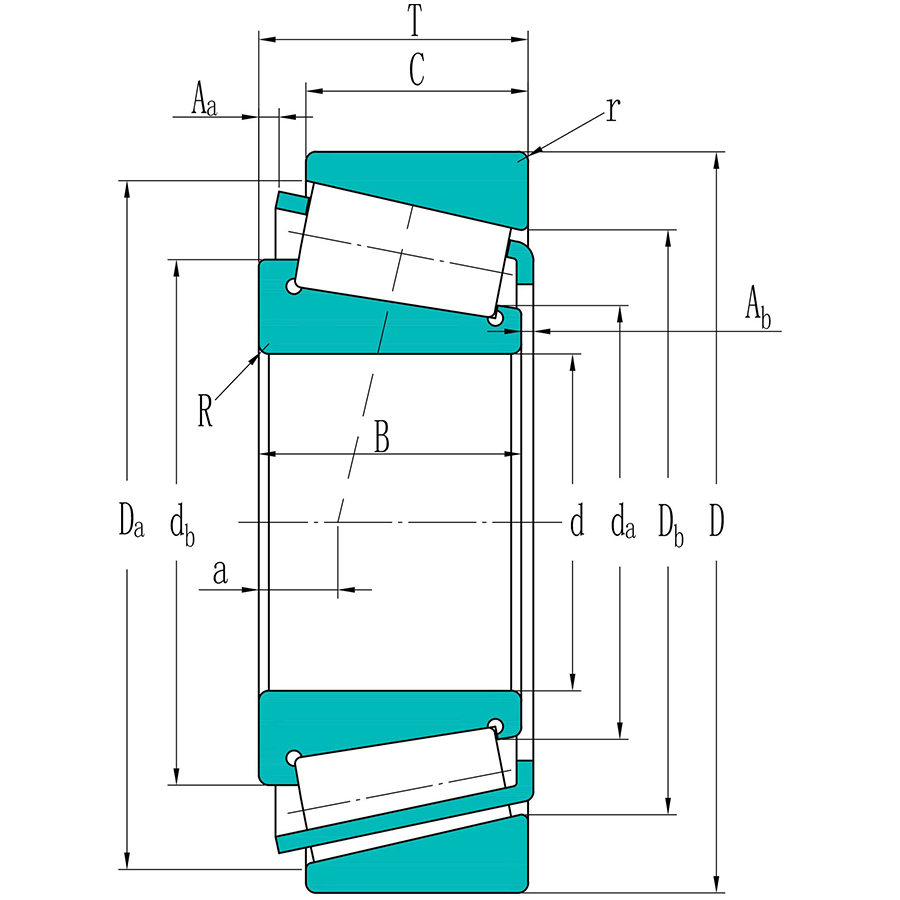

32020X Tapered Roller Bearing, high load-bearing capacity, high rigidity, Bore is 100 mm, Cup outer diameter (D) is 150 mm, Bearing width (T) is 32 mm, Weight is 1.89 kg, suitable for wheelsets and axle boxes of locomotives, gearboxes and harvesters, etc., and is the most widely used bearing in working conditions with high load-bearing capacity requirements.

QIBR - 32020X Tapered Roller Bearing Characteristics

32020X Tapered Roller Bearing, long life, easy installation and maintenance, strong adaptability. 32020X Tapered Roller Bearing, can withstand radial load, certain axial load and overturning moment, suitable for mechanical equipment with high durability requirements.

32020X Tapered Roller Bearings Features and Advantages

Strong Load Capacity: Tapered roller bearings can withstand significant radial and axial forces, making them particularly suitable for handling combined loads. The axial load capacity depends on the contact angle; the larger the contact angle, the greater the axial load capacity.

High Precision: These bearings are manufactured using grinding processes, ensuring high precision, which is essential for applications requiring exacting standards.

Adjustable Clearance: During installation, the clearance can be adjusted by modifying the relative positions of the inner and outer rings, optimizing performance.

Good Rigidity and Impact Resistance: The compact structure of tapered roller bearings provides excellent rigidity and outstanding impact resistance.

Application: They are widely used in fields such as gearboxes, lifting equipment, rolling mills, automotive, metallurgy, petroleum, mining machinery, mechanical manufacturing, and aerospace.

QIBR - 32020X Tapered Roller Bearings Optimization

Heat Treatment: The manufacturing process is optimized through martensitic quenching (standard) and surface hardening heat treatment.

Cage Type: The type of cage is selected based on customer requirements and operating conditions, including options like stamped cages, glass fiber reinforced PA66 cages, and PEEK cages.

Special Variants: For specific application requirements, options include solid oil bearings, INSOCOAT insulated bearings, and NoWear non-wearing coated bearings.

More customization: QIBR can design and optimize bearings based on customer drawings and operational needs.

QIBR - 32020X Tapered Roller Bearings Quality Control

Dimension measurement: Various high-precision instruments are used to measure multiple dimensions of the bearings, achieving a maximum precision of 0.001mm.

Rotation accuracy: A dial gauge is employed to measure minor surface imperfections or deviations, with a measurement precision of up to 0.001mm.

Hardness measurement: Surface hardness is measured using a hardness tester, with a precision of ±0.5 HRC.

Metallographic analysis: Professional metallographic microscopes are used to analyze the internal metallographic structure of the metal.

Geometric tolerance: A profile meter measures the geometric shape and relative positions of the bearings.

Noise monitoring: Vibration monitoring devices assess the vibration conditions during operation to derive noise data.

Raw material control: Steel and parts are sourced from ISO 14001-certified suppliers, ensuring product stability while promoting sustainable development.

Features & Benefits

Tapered roller bearings feature a cup and cone assembly. The cup is comprised of the outer ring and the cone assembly consists of inner ring, rollers, and cage. This bearing construction accommodates combined loads and provides low friction during operation. By adjusting one single row tapered roller bearing against a second tapered roller bearing and applying a preload, a rigid bearing application can be achieved.

Downloads