Delivery of QIBR Ultra-Precision Angular Contact Ball Bearings and High-Speed Deep Groove Ball Bearings to a Customer in the UK for Enhancing Precision and Speed of Machine Tool Spindles and Electric Spindles

- Continent

- Europe

- Country

- United Kingdom

- Date

- 2016-01-17

- Applications

- Electrical,Machine tool spindle

Products Used

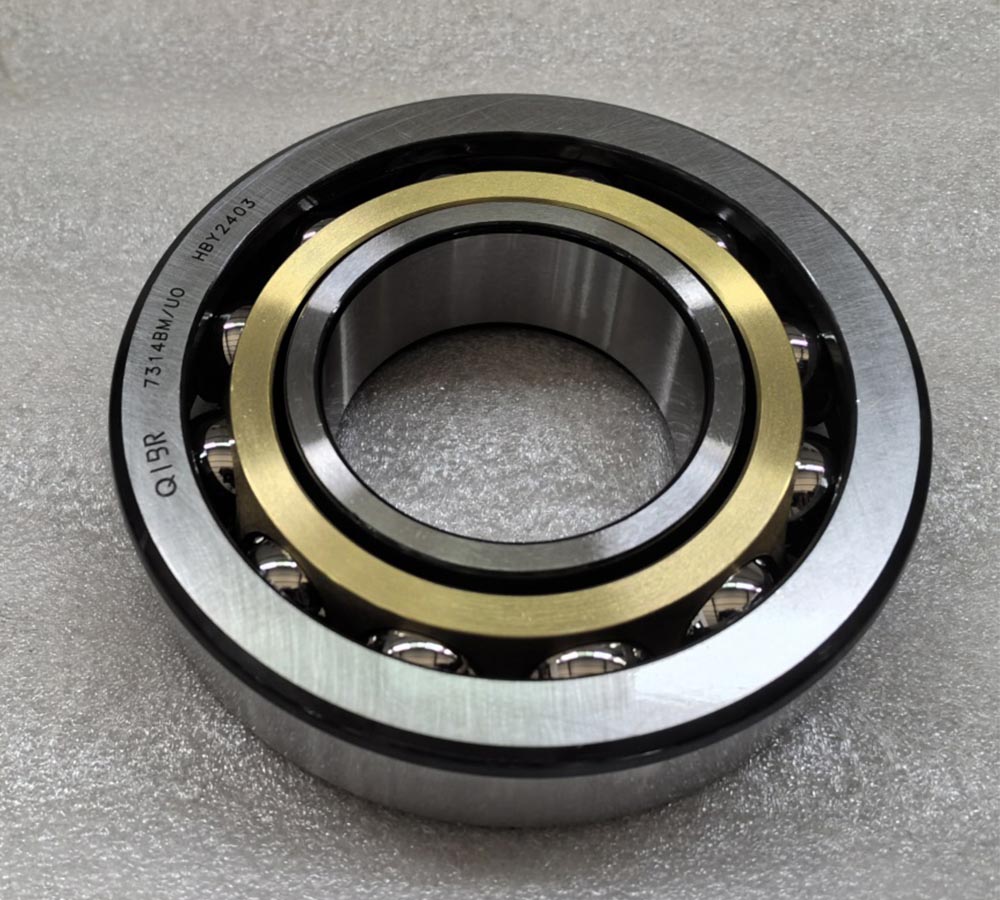

Ultra-Precision Angular Contact Ball Bearings & High-Speed Deep Groove Ball Bearings

1. High-Speed Performance: QIBR’s angular contact ball bearings are designed with an optimized contact angle between the rolling elements and the inner and outer rings, allowing them to handle both radial and axial loads at high speeds.

High-Speed Deep Groove Ball Bearings: Made from high-quality steel and precision-machined, these bearings ensure high-speed performance while maintaining low noise and vibration levels.

2. High Rigidity: Angular Contact Ball Bearings: Designed with preload, these bearings offer significantly increased rigidity, reducing displacement caused by load variations during operation.

Deep Groove Ball Bearings: The deep groove design provides a large contact area, allowing the rolling elements to better handle radial and axial loads. This large contact area helps distribute the load, reducing deformation and improving rigidity.

3. High Precision: Ultra-Precision Angular Contact Ball Bearings: With precision up to P4 grade, QIBR’s angular contact ball bearings meet the stringent accuracy requirements of high-speed CNC machine tool spindles.

High-Speed Deep Groove Ball Bearings: These bearings achieve P2 grade precision, providing excellent rotational accuracy while ensuring high-speed performance.

Additional Notes:

The UK customer chose QIBR’s high-precision deep groove ball bearings and ultra-precision angular contact ball bearings as an equivalent replacement for NMB bearings to meet the precision and high-speed requirements of machine tool spindles and electric spindles. QIBR’s bearings use advanced manufacturing processes to ensure exceptional geometric precision and surface finish. This precision design allows the bearings to remain stable at high speeds, reducing vibration and noise, and enhancing the overall accuracy of machine tool spindles and electric spindles. QIBR’s high-precision deep groove ball bearings and angular contact ball bearings are ideal choices due to their high precision, rigidity, speed, durability, and ease of maintenance, making them perfect for demanding spindle applications.