The slewing bearings of QIBR were delivered to a customer in Montreal, Canada, to enhance the stability and durability of the blow molding machine

- Continent

- North America

- Country

- Canada

- Date

- 2016-08-18

- Categories

-

Slewing Bearing

- Applications

- Blow Molding Machine

Products Used

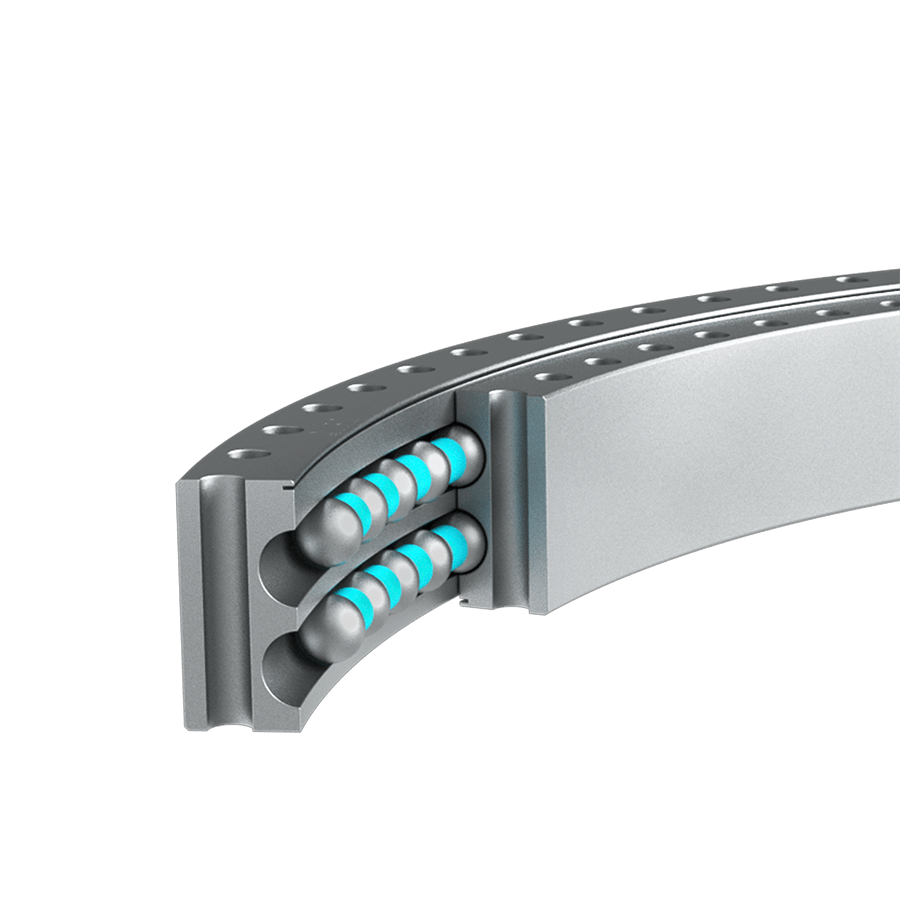

Slewing Bearing

1. High load capacity: The Q16283001 slewing bearings can simultaneously bear large radial, axial and overturning moments, achieving high load-bearing capacity within a small space, improving the overall stability and reliability of the blow molding machine. They maintain stability under the high-load operating conditions of the blow molding machine.

2. Precise Positioning: The Q16283001 slewing bearings have a high-precision rolling element contact mode, ensuring that the positioning accuracy of the blow molding machine is very high during high-speed rotation and frequent start-stop processes. This ensures that the bottles can be evenly heated and formed.

3. Reduction of Vibration and Noise: The Q16283001 slewing bearings can effectively reduce vibration and noise, reduce the wear of the machine, and avoid precision errors caused by vibration. They ensure that the blow molding machine is not affected by excessive vibration, reduce the instability in the production process, and guarantee the product quality.

Additional Notes:

The Canadian customer decided to purchase the Q16283001 slewing bearings of QIBR Company to improve the stability and durability of the blow molding machine. The Q16283001 slewing bearings adopt advanced precision machining technologies to ensure that the bearings meet the high standards of the industry in terms of size, surface finish and tolerance control, ensuring that the blow molding machine maintains excellent running stability during high-speed rotation and frequent movements. The Q16283001 slewing bearings are made of high-strength alloy steel materials and undergo strict heat treatment processes, having a higher load-bearing capacity. The blow molding machine can operate stably for a long time under high-load working environments, reducing the downtime.