The slewing bearings of QIBR were delivered to the customer in Mumbai, India, to improve the smoothness and durability of the fire truck

- Continent

- Asia

- Country

- India

- Date

- 2016-08-31

- Categories

-

Slewing Bearing

- Applications

- Fire Truck

Products Used

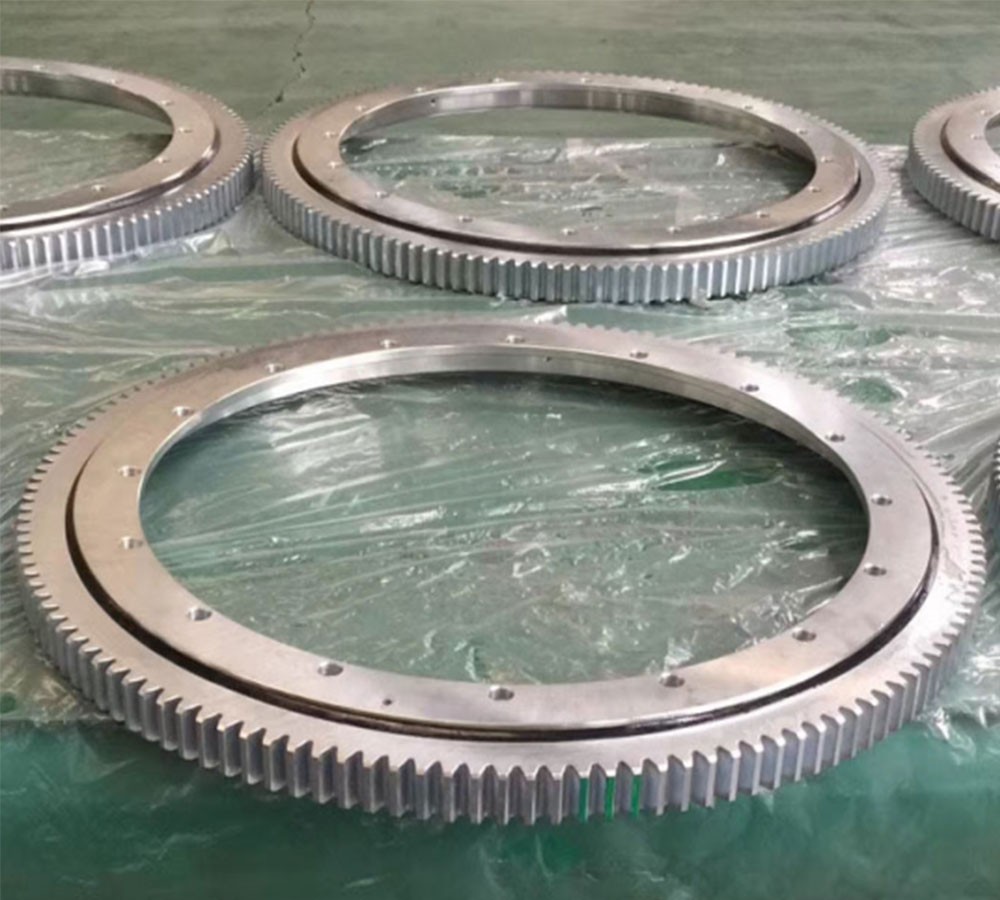

Slewing Bearing

1. High load capacity: The 112.25.630 slewing bearings can simultaneously bear large radial, axial and overturning moments. When operating on uneven ground or slopes, they can provide the necessary support and stability for the fire truck. The 112.25.630 slewing bearings can effectively absorb the impact forces generated by the fire truck during rapid movement and sudden stops, keeping the fire truck operating normally.

2. Durability and Reliability: The 112.25.630 slewing bearings are made of high-performance materials and advanced manufacturing processes, possessing good wear resistance and fatigue resistance. They can maintain stable performance under high loads and in harsh environments, reducing the maintenance frequency.

3. Excellent Rotational Precision: The 112.25.630 slewing bearings can operate flexibly within a large rotation angle. They can maneuver and adjust in a narrow space to quickly position the nozzle. They provide a smooth rotational movement, improving the accuracy and safety of the operation.

Additional Notes:

The Indian customer decided to purchase the 112.25.630 slewing bearings of QIBR Company to meet the requirements of improving the smoothness and durability of the fire truck. QIBR Company has advanced manufacturing technologies and equipment. The 112.25.630 slewing bearings have undergone strict quality control to ensure the high precision and consistency of the bearings. The bearings are made of high-performance materials and have a precise design, with superior load-bearing capacity, ensuring the smoothness and durability of the vehicle under high-load conditions. The 112.25.630 slewing bearings are coated with special coatings and made of materials that are resistant to high temperatures and corrosion, ensuring that they can maintain their best performance under harsh working conditions.