The slewing bearings of QIBR were delivered to the customer in Lyon, France, to improve the smoothness and load-bearing capacity of the disc feeder

- Continent

- Europe

- Country

- France

- Date

- 2016-07-01

- Categories

-

Slewing Bearing

- Applications

- Disc feeder

Products Used

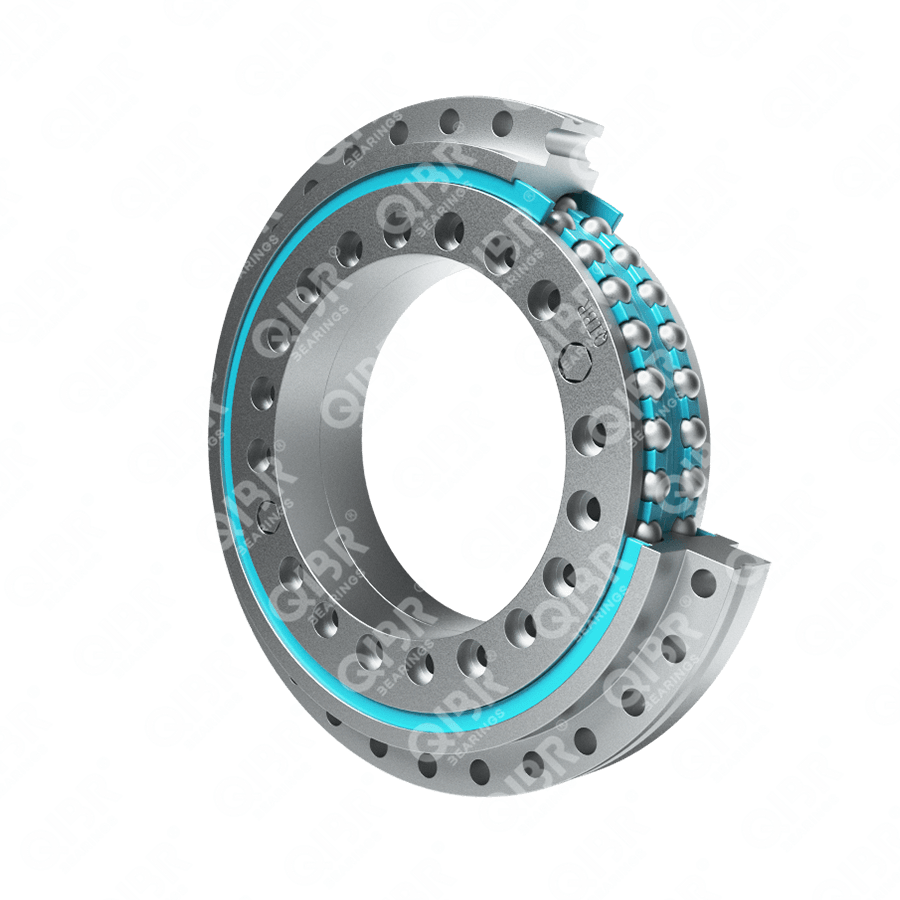

Slewing bearing

1. Strong Load Capacity: The ZKLDF120 slewing bearing is made of high-strength alloy steel material, possessing excellent compressive and flexural resistance properties and being able to bear larger loads. The ZKLDF120 slewing bearing can simultaneously withstand relatively large radial and axial loads, remaining stable during the handling of heavy materials when the disc feeder is in operation, thus reducing the risk of failures caused by uneven loading.

2. Compact Structure: The ZKLDF120 slewing bearing integrates multiple functional components together, reducing the number of components and lowering the complexity and volume of the overall structure. It realizes efficient rotation functions within a limited space, facilitating installation and maintenance.

3. Smooth Rotatio: The ZKLDF120 slewing bearing, through advanced processing technologies, ensures the fitting accuracy and surface finish among various components, having good rotation performance and being able to ensure that the disc feeder transports materials smoothly and noiselessly during its operation.

Additional Notes:

The French customer decided to purchase the ZKLDF120 slewing bearings of QIBR Company with the aim of enhancing the smoothness and load-bearing capacity of their disc feeder. The ZKLDF120 slewing bearing adopts high-end materials and advanced technologies, possessing excellent wear resistance and durability. It maintains good performance in extreme working environments and reduces the incidence of failures. The ZKLDF120 slewing bearing, through optimized design and precise manufacturing processes, can effectively disperse loads and improve the load-bearing capacity. The disc feeder can handle larger material loads, improving the overall production efficiency and reducing the risk of damage caused by overloading.