QIBR 020.50.2000 Slewing Bearing Delivered to a UK Customer in London for Enhanced Safety in Metallurgical Furnaces

- Continent

- Europe

- Country

- United Kingdom

- Date

- 2016-02-19

- Categories

-

Slewing Bearing

- Applications

- Metallurgy,Furnace

Products Used

Slewing Bearing

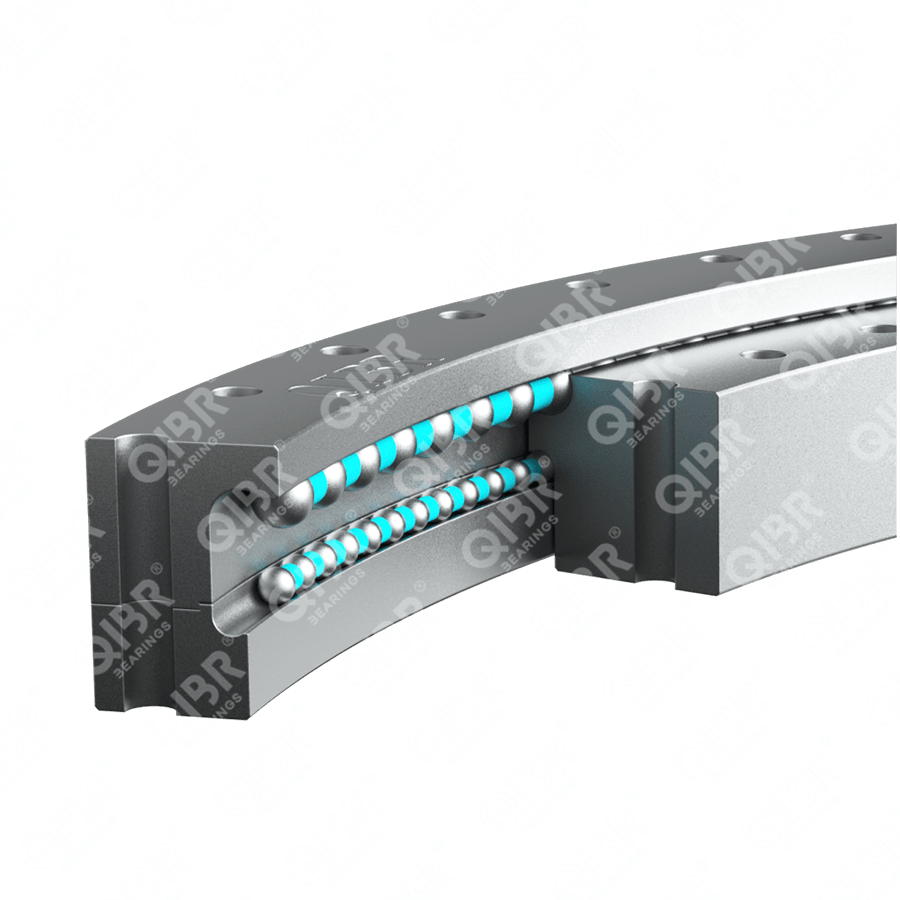

1. High Load Capacity: The 020.50.2000 slewing bearing can withstand large radial, axial loads, and overturning moments simultaneously. During the metallurgical process, furnaces endure high temperatures and heavy loads. The high load capacity of the 020.50.2000 slewing bearing ensures the safe and stable operation of the equipment.

2. Stability and Reliability: The 020.50.2000 slewing bearing effectively distributes loads, reduces stress concentration, and improves stability and reliability. Manufactured from high-strength, wear-resistant materials, it offers excellent mechanical properties and fatigue resistance, which are critical for the continuous operation of metallurgical furnaces. This reduces failure rates and extends the service life of the equipment.

3. Vibration Resistance: The 020.50.2000 slewing bearing effectively resists vibration and impact loads. Its double-row roller design enhances load distribution and vibration resistance. Multiple rollers work simultaneously, countering vibrations and shocks from various directions, ensuring the stability of the equipment in dynamic operating conditions.

Additional Notes:

The UK customer decided to purchase QIBR's 020.50.2000 slewing bearing to meet the safety and stability requirements of their metallurgical furnace. The well-designed structure of the 020.50.2000 slewing bearing enhances safety and helps reduce failure rates. QIBR bearings undergo strict quality control and testing to ensure reliability under high-load and high-temperature conditions. Customers can use them with confidence, minimizing safety risks caused by bearing failures.