QIBR Crossed Roller Bearings were delivered to a customer in Rome, Italy, to enhance the high precision and load-bearing capacity of the rotary table of a CNC machine tool

- Continent

- Europe

- Country

- Italy

- Date

- 2016-08-17

- Categories

-

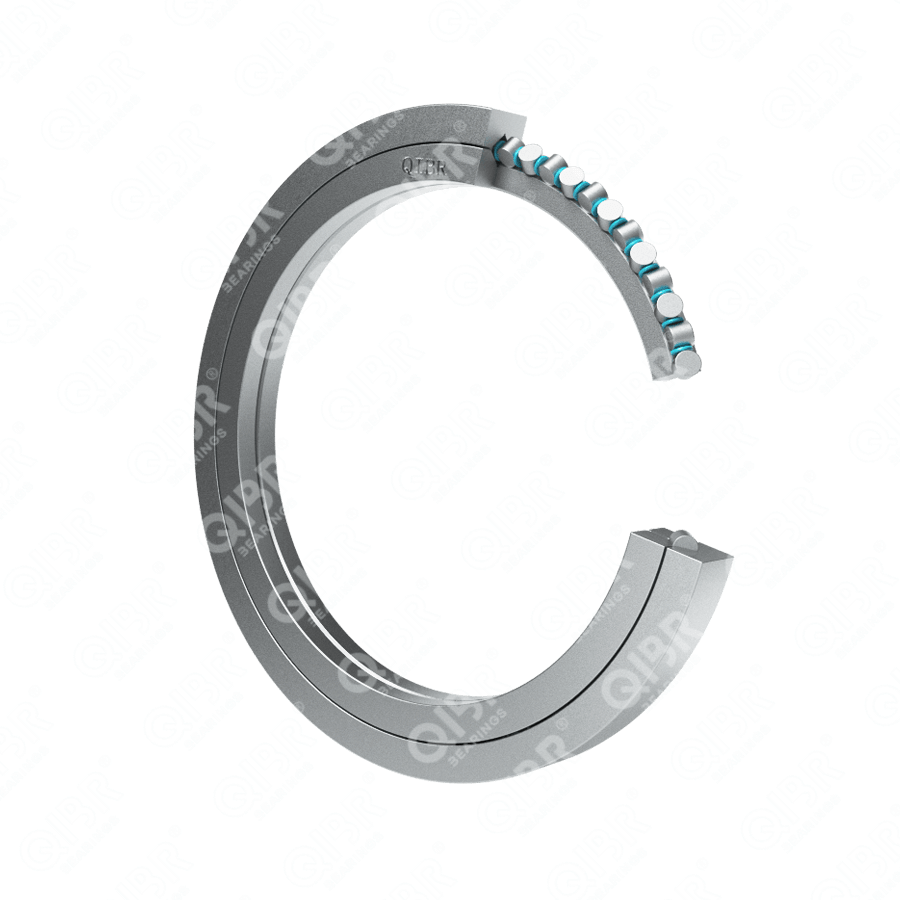

Cross Roller Bearing

- Applications

- Rotary Table of CNC Machine Tool

Products Used

Crossed Roller Bearings

1. High Load Capacity: The QXR496051 crossed roller bearings, with their precisely arranged roller structure, have numerous contact points and a wide load-bearing surface. They can withstand large radial, axial, and tilting loads. During the rotary motion of the machine tool, they can effectively reduce deformation and motion errors, keeping the worktable stable.

2. Precision Positioning: The rotary table of a CNC machine tool demands extremely high precision. The QXR496051 crossed roller bearings possess the characteristic of low backlash and provide precise positioning during rotation. They can offer high rotational precision and low errors and maintain stability even under long-term, high-load working conditions.

3. Self-locking and Anti-vibration Properties: The QXR496051 crossed roller bearings have a certain self-locking property when under force. When operating under high load and at high speed, they can effectively prevent the worktable from reverse rotation or vibration, maintaining the high precision and stability of the machine tool.

Additional Notes:

The Italian customer decided to purchase the QXR496051 crossed roller bearings from QIBR Company to meet the requirements of high precision and load-bearing capacity for the rotary table of their CNC machine tool. The QXR496051 crossed roller bearings feature a unique design with internal rollers arranged in a vertically crossed manner, enabling them to bear loads in multiple directions simultaneously. They are suitable for the rotary table of CNC machine tools that require high precision and high stability. The QXR496051 crossed roller bearings can provide extremely high radial and axial rigidity and maintain excellent stability during high-speed rotation. By using QIBR's bearings, the Italian customer's machine tool can maintain higher precision during high-speed machining, reduce machining errors caused by vibration and instability, and improve the overall quality and consistency of the products.