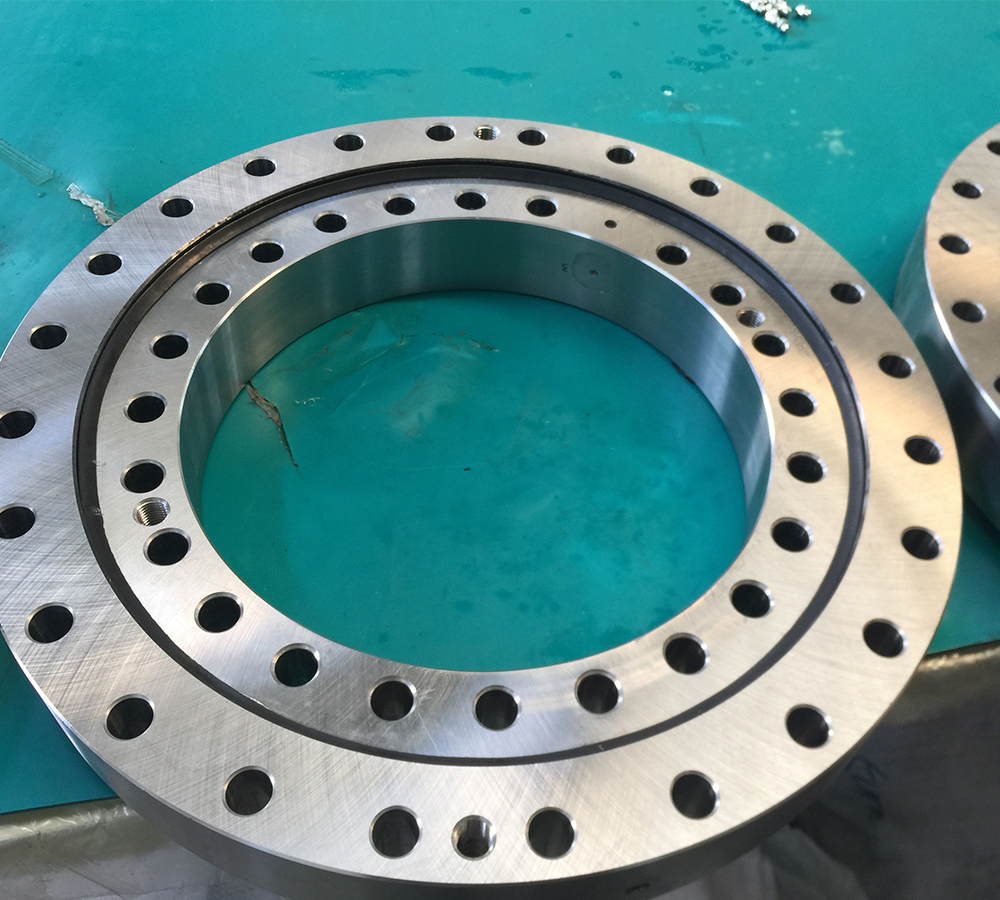

QIBR delivered the Q16337001 slewing bearing to a customer in Frankfurt, Germany, for use in a filling machine in the chemical industry, enhancing stability and precision.

- Continent

- Europe

- Country

- Germany

- Date

- 2016-03-24

- Categories

-

Slewing Bearing

- Applications

- Chemical Industry Filling Machine

Products Used

Slewing bearing

1. High Load Capacity: The Q16337001 slewing bearing features a large diameter and wide contact surface design, effectively dispersing loads and reducing localized pressure. It can handle radial, axial, and overturning moments, ensuring stability for heavy equipment and high-load operations in the filling machine.

2. Precise Positioning Ability: Made from high-strength, high-hardness, and wear-resistant materials, the Q16337001 can support significant loads while minimizing deformation, providing high-precision rotation and control over each action in the filling process, crucial for production efficiency and product quality.

3. Low Friction and High Efficiency: The Q16337001 is crafted with precision to ensure optimal fit between rolling elements, raceways, and other components, reducing friction losses. This results in lower energy consumption and increased operational efficiency of the equipment.

Additional Notes:

Stability and precision in filling machines are vital for ensuring production efficiency and product quality in the chemical industry. After considering various factors, the German client chose the QIBR Q16337001 slewing bearing to meet their high production standards. QIBR’s engineering team designed the Q16337001 with the chemical industry's specific needs in mind, ensuring excellent performance under heavy loads and complex working conditions, thus enhancing the overall performance of the filling machine. Stable equipment performance leads to higher production efficiency, shorter production cycles, increased output, and ultimately greater corporate profits.